Process for making dilation vitrified microbead and rotary floating dilation vitrification furnace

The technology of expanded vitrified microbeads and expanded vitrified furnace is applied in the field of rotary-floated expanded vitrified furnace, which can solve the problems of difficult to solve the control of the production process, unable to form spherical vitrified particles, not meeting the requirements of energy-saving development, and the like. The effect of increasing residence heating time, compact structure and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

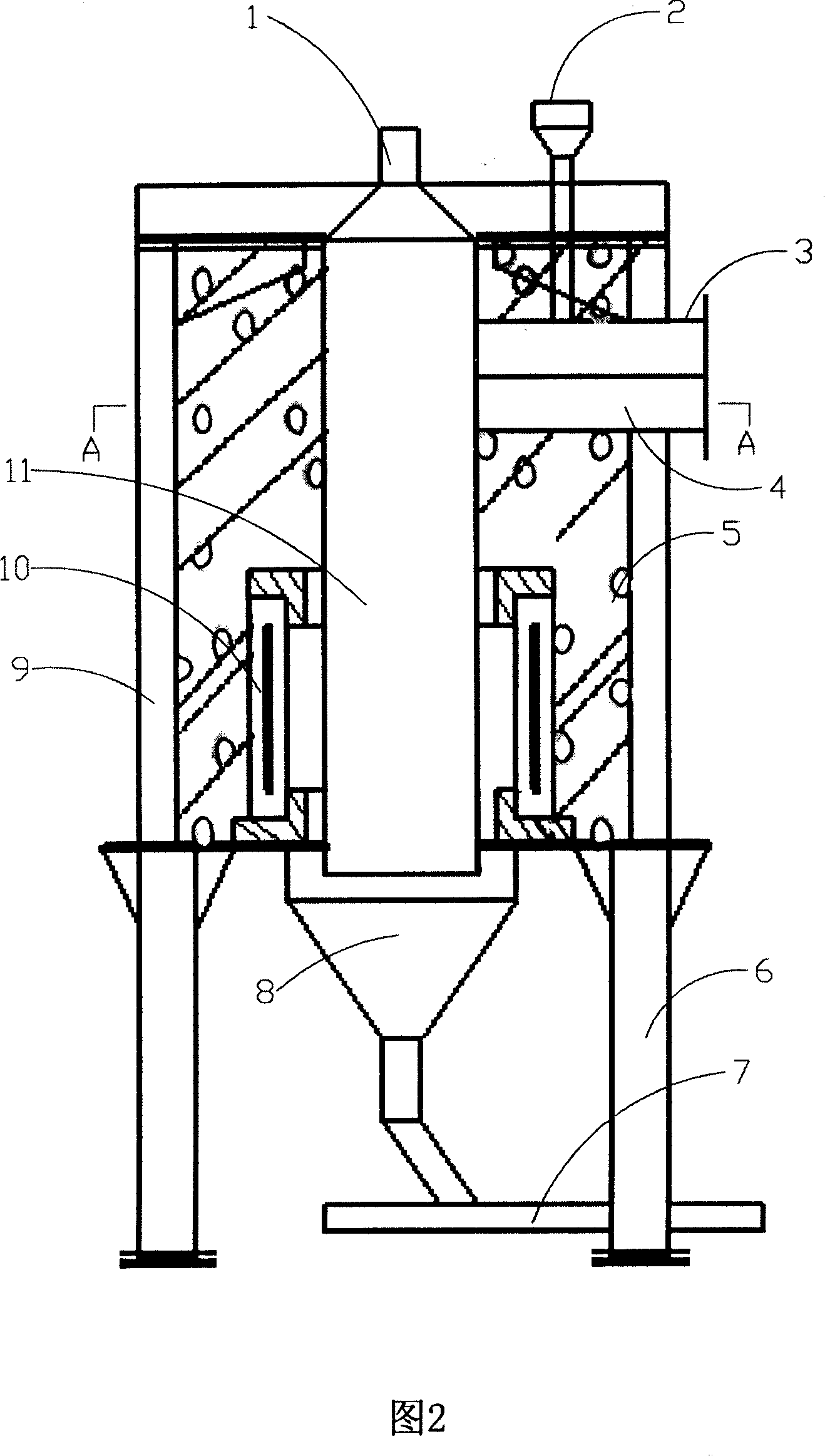

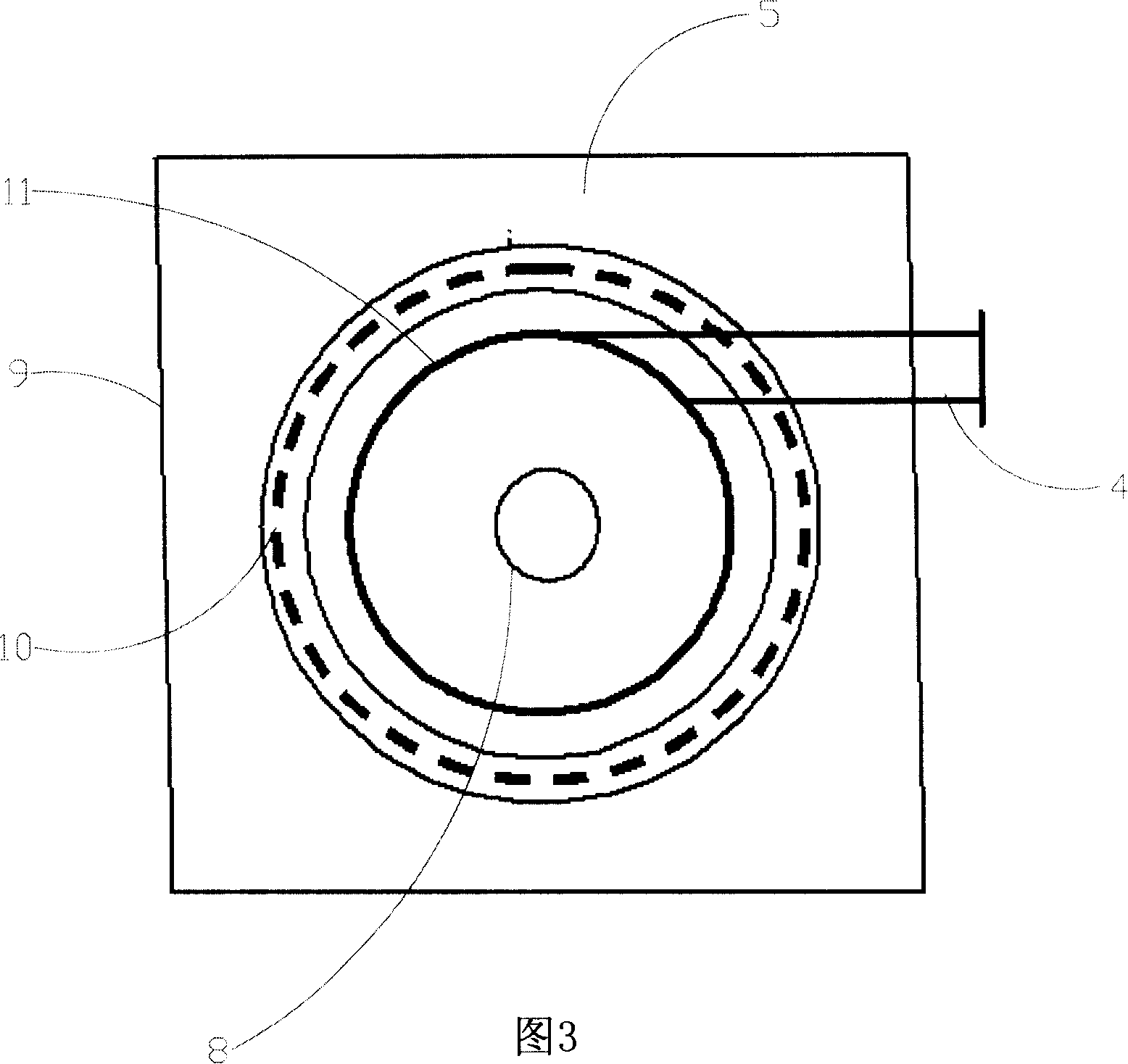

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] As shown in Fig. 2 and Fig. 3, a kind of rotary-floating expansion vitrification furnace that the present invention relates to comprises a furnace shell, a furnace body and a furnace body support, and the furnace body shell and the furnace body are arranged on the furnace body support Above, it also includes a lower sand hopper, a lower sand preheating gas pipe, and an expansion gas pipe. The sand bucket communicates with the lower sand preheating gas pipe, and there may be one or several expansion gas pipes, which are respectively arranged below the lower sand preheating gas pipe.

[0027] The lower sand bucket is arranged above the lower sand preheating gas pipe.

[0028] An electric heating tube is arranged on the lower side of the furnace body.

[0029] The lower part of the furnace body is provided with a cooling collection bucket connected thereto, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com