Magnesia-alumina spinel stemming

The technology of magnesia-aluminum spinel and taphole clay is applied in the field of metallurgical refractory materials, which can solve the problems of cracks in taphole clay, infiltration of taphole clay, and erosion damage, etc. Good thermal shock resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

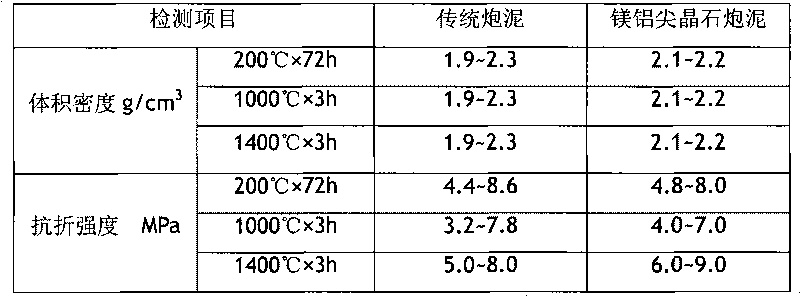

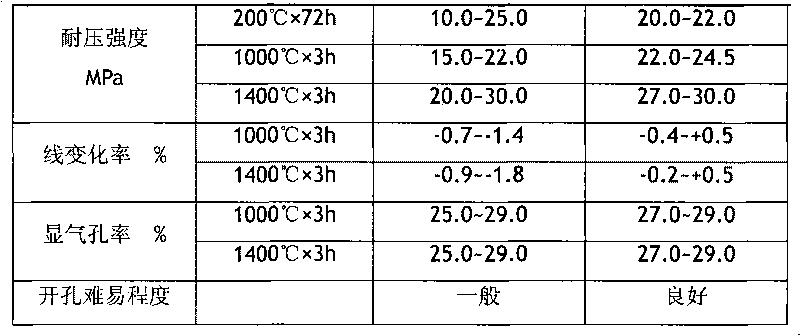

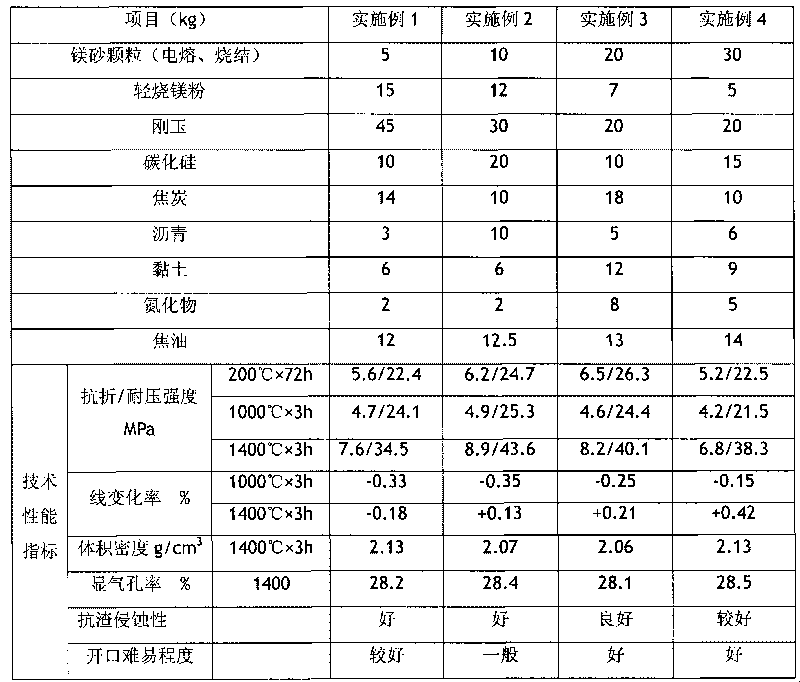

[0028] Table 2 lists the raw materials of the present invention for the magnesia-aluminum spinel blast furnace clay for tapping holes, their contents measured in parts by weight, and main technical performance indicators.

[0029] Table 2 each embodiment and performance

[0030]

[0031] The manufacture method of each embodiment is identical, and its method is as follows:

[0032] First, according to the mass measurement ratio in Table 2, weigh magnesia particles, lightly burned magnesium powder, corundum, asphalt, clay, silicon carbide, coke, nitride and various refractory raw materials, mix them evenly and put them in bags for later use.

[0033] Pour the mixed bulk material into the test mixer, add an appropriate amount of tar and mix it for about 30 minutes. After the tar wets the bulk material evenly, measure the Masha value with a Masha instrument, and record the temperature of the clay at that time. When the temperature is suitable for plasticity, it can be rammed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com