Method for remaking common window into thermal insulation energy saving window

A common window technology, which is applied in the field of transforming ordinary windows into heat-insulating and energy-saving windows, which can solve the problems of high cost and complicated window manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

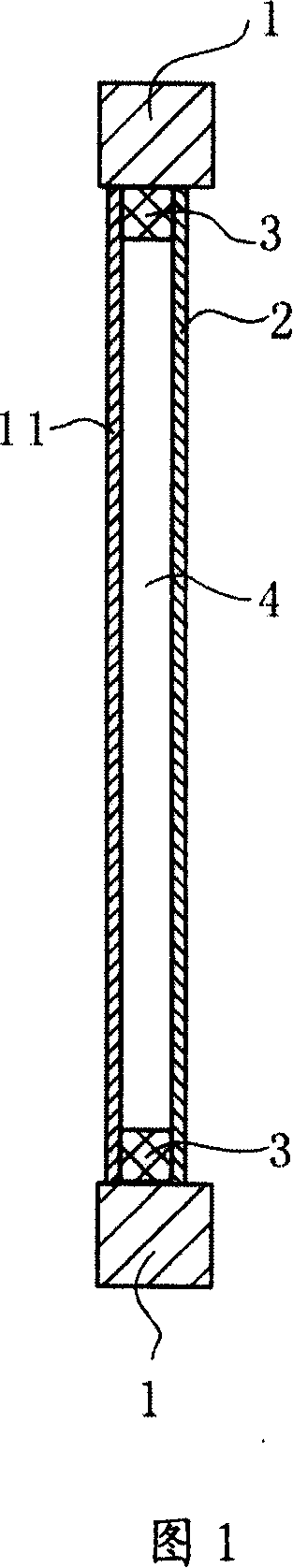

[0016] A method of transforming ordinary windows into heat-insulating and energy-saving windows is completed by using soft glass 2 and pasting strips 3 directly purchased from the market on the basis of ordinary windows 1:

[0017] First, the soft glass 2 is cut to the size of the window glass 11;

[0018] Then, stick the sticker 3 around the soft glass 2 with glue or double-sided self-adhesive;

[0019] Finally, use glue or double-sided self-adhesive to adsorb the soft glass with the sticker 3 on the window glass 11.

[0020] Finally, the structure of the heat-insulating and energy-saving window after transformation is shown in FIG. 1 . The soft glass 2 and the window glass 11 are separated by strips 3 to form a non-flowing air layer 4 .

[0021] The thickness of the sticker 3 is 12-16mm, and the soft glass 2 is coated colored soft glass or transparent colorless soft glass. Of course, this method can also be used to transform ordinary windows into thermal insulation and ene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com