A kind of high temperature resistant heat insulation material using industrial tailings and its preparation method

A technology for thermal insulation and industrial tailings, applied in the field of thermal insulation materials, can solve the problems of high preparation cost, difficult quality control, complicated operation, etc., and achieve the effects of low cost, simple process and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

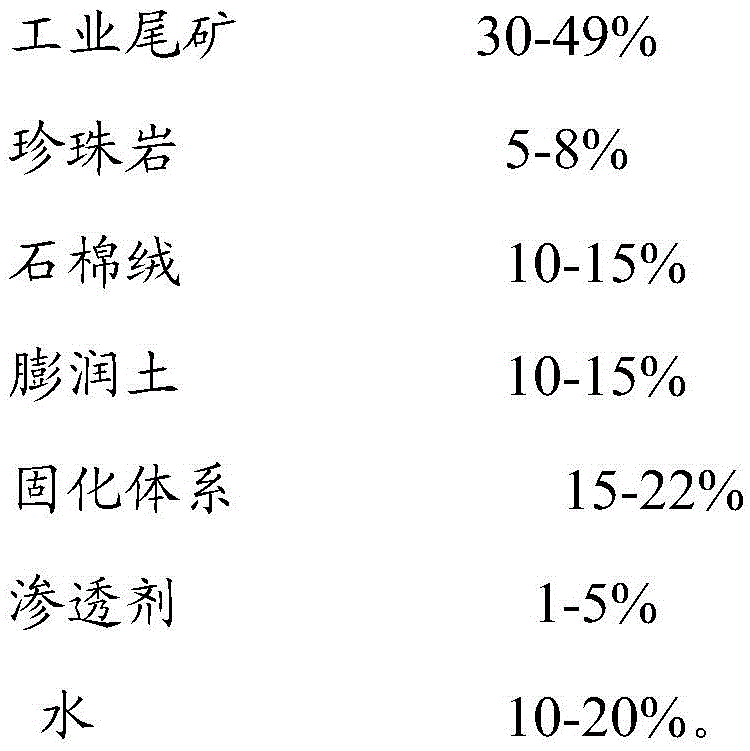

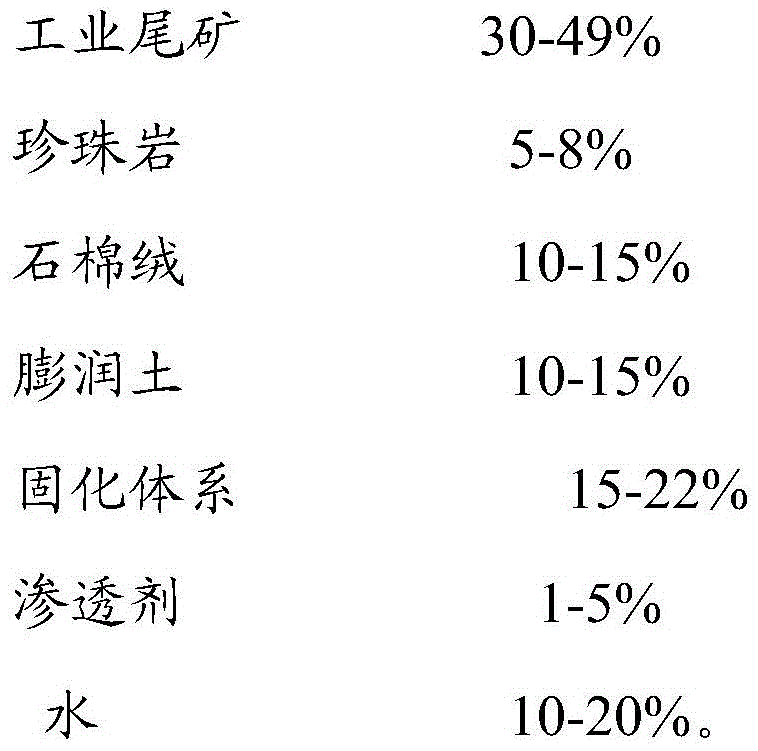

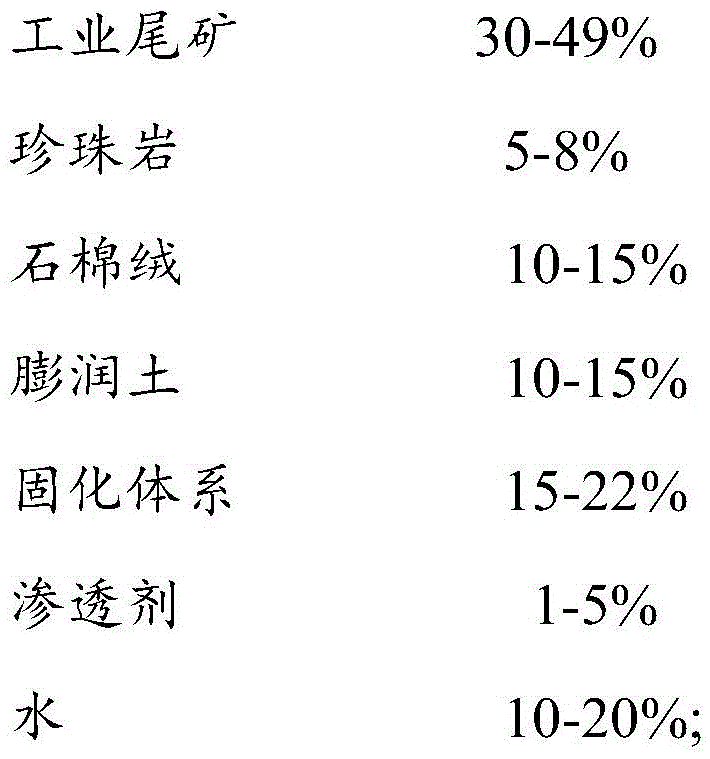

[0027] Correspondingly, the embodiment of the present invention also provides a method for preparing a high-temperature-resistant thermal insulation material using industrial tailings, which includes the following preparation steps:

[0028] S01. Weigh each component according to the formula of the above-mentioned high temperature heat insulation material;

[0029] S02. Weigh each component for mixing treatment to obtain a thick mixture;

[0030] S03, sealing and storing the thick mixture.

[0031] Specifically, in step S01, each component is weighed according to the formula of the above-mentioned high-temperature heat-insulating and heat-insulating material, for example, according to the weight percentage of the above-mentioned industrial tailings, perlite, asbestos wool, bentonite, curing system and penetrant.

[0032] In the above step S02, the time for each component to be mixed can be flexibly adjusted according to the actual production conditions, as long as each component is full...

Embodiment 1

[0037] A high-temperature thermal insulation material using industrial tailings, including industrial tailings 40%, perlite 5%, asbestos wool 10%, bentonite 14%, potassium silicate 16%, aluminum tripolyphosphate 4%, penetrant 1% and water 10%.

[0038] The preparation steps are:

[0039] Step 1: Weigh the raw materials according to the above-mentioned mass ratio;

[0040] Step 2: First soak the asbestos wool in clean water for more than 5 hours, add industrial tailings, perlite, bentonite and penetrant and stir evenly, and finally add potassium water glass and aluminum tripolyphosphate and mix evenly. Add appropriate amount of water to keep it thick during the process shape.

[0041] The third step: bagged and sealed and stored.

[0042] After testing, the properties of the product obtained after curing at 80°C are: 1) Density 697Kg / m 3 2) Compressive strength after 24h is 1.52Mpa; 3) Curing time is 5.5h; 4) Thermal conductivity is 0.113W / m; 5) There is no crack after curing, and the ...

Embodiment 2

[0044] A heat-resistant thermal insulation material using industrial tailings, including industrial tailings 45%, perlite 5%, asbestos wool 14%, bentonite 10%, sodium silicate 10%, aluminum tripolyphosphate 5%, penetrant 1% and water 10%.

[0045] The preparation steps are:

[0046] Step 1: Weigh the raw materials according to the above-mentioned mass ratio;

[0047] Step 2: First soak the asbestos wool in clean water for more than 5 hours, add industrial tailings, perlite, bentonite and penetrant and stir evenly, and finally add potassium water glass and aluminum tripolyphosphate and mix evenly. Add appropriate amount of water to keep it thick during the process shape.

[0048] The third step: bagged and sealed and stored.

[0049] After testing, the performance of the product obtained after curing at room temperature is: 1) Density 655Kg / m 3 2) Compressive strength after 24h is 1.39Mpa; 3) Curing time is 7h; 4) Thermal conductivity is 0.106W / m; 5) There is no crack after curing, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com