Baking-free building block produced by utilizing nonmetallic waste slag and preparation method

A non-metal and block technology, applied in the field of building materials, can solve problems such as defective performance and uneconomical performance, and achieve the effects of small expansion and contraction deformation, energy saving and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

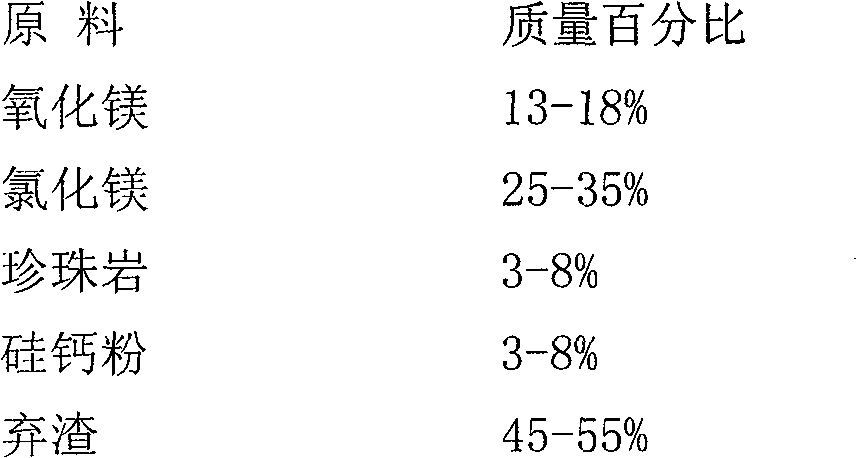

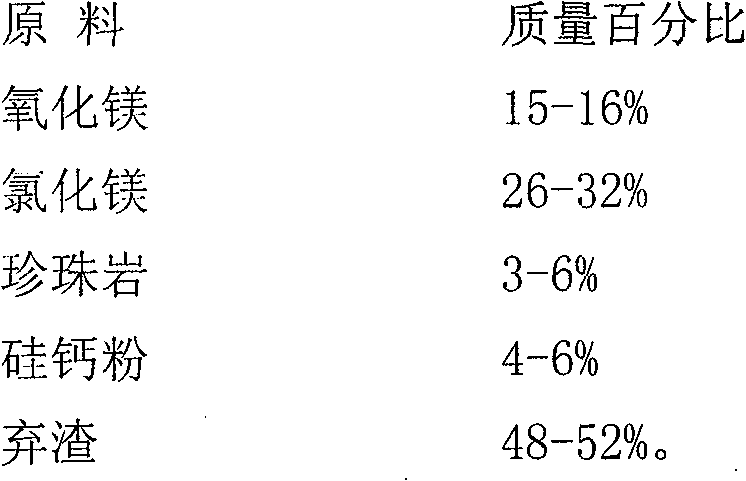

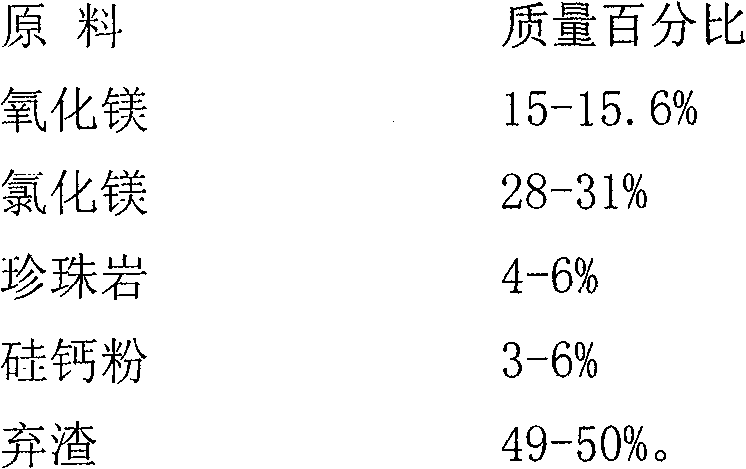

[0034] A kind of proportioning that utilizes non-metallic waste slag to produce unfired block (brick) is as follows (using mass percentage):

[0035]

[0036] Its preparation steps are as follows:

[0037] 1. According to local conditions, waste slag is selected as the additive material (including fly ash, sawdust, river sand, and crop straw powder), the percentage content is greater than 45%, and the particle size and mesh number are above 60. Powder ash, desulfurized gypsum, construction waste, etc. are used; sawdust, river sand, rice husk powder, etc. can be used in rural areas.

[0038] 2, in above-mentioned raw material, add magnesium oxide powder in proportion, preferably select the magnesium oxide powder (its content is more than 80%, and activity is more than 55%) produced in Haicheng, Liaoning, and general addition is 15%.

[0039] 3. Magnesium chloride (with a content of about 46%) is formulated with tap water (24 hours in advance) into a solution of 25Be' (Baume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| drying shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com