Water-based anticorrosive paint, preparation and application in field of concrete structure protection

A water-based technology for anti-corrosion coatings, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of loose paint film, alkali return, large gaps, etc., and achieve dense coating film, excellent anti-corrosion performance, and mechanical properties excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

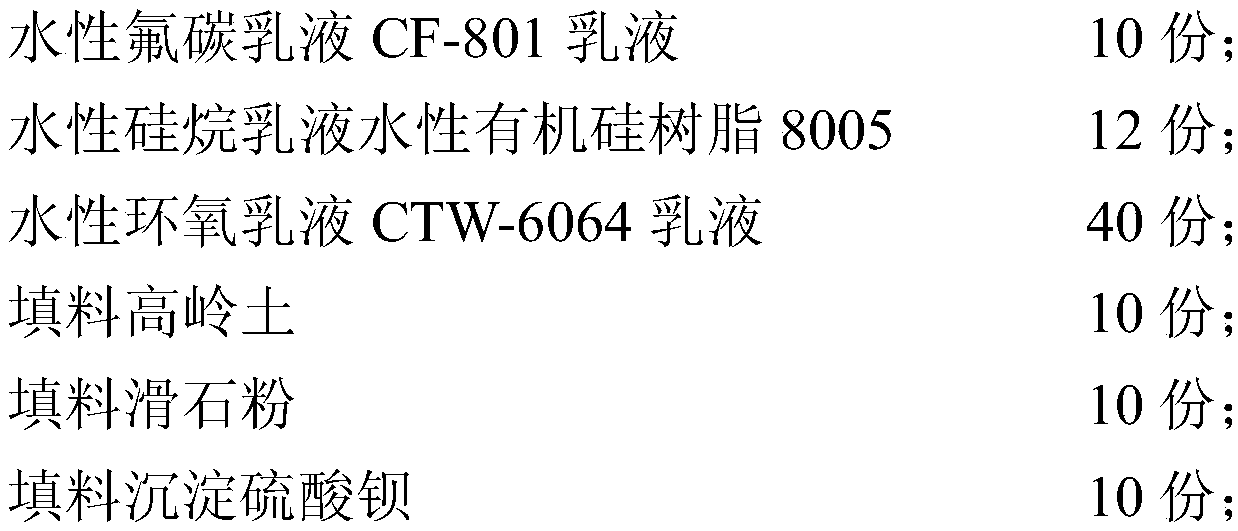

Embodiment 1

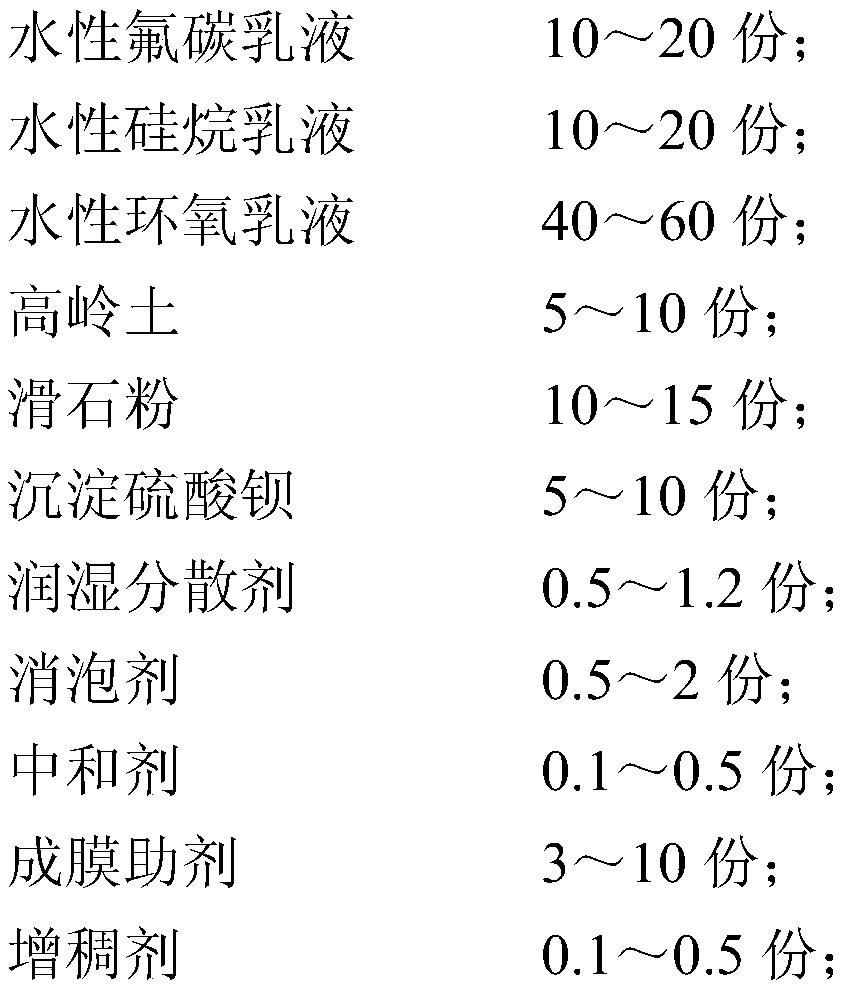

[0042] A kind of water-based anticorrosion paint, comprises A component and B component, wherein, described A component comprises following component by weight:

[0043]

[0044]

[0045] The B component is water-based alicyclic amine curing agent CTW-6061 (B);

[0046] The preparation method of described waterborne anticorrosion paint, comprises the steps:

[0047] (1) Refining stage: Add wetting and dispersing agent, neutralizer, defoamer and part of deionized water into the dispersion tank, disperse at low speed (300r / min) for 10min, then add kaolin and talc powder and precipitated barium sulfate, and disperse at high speed (1000r / min) for 20 minutes. After the dispersion is completed, transfer to a sand mill for grinding until the fineness is ≤40 μm to obtain mixture Ⅰ;

[0048] (2) Paint let-down stage: Add the water-based fluorocarbon emulsion, water-based silane emulsion and water-based epoxy emulsion of the water-based anti-corrosion coating into the dispersion ...

Embodiment 2

[0051] A kind of water-based anticorrosion paint, comprises A component and B component, wherein, described A component comprises following component by weight:

[0052]

[0053]

[0054] The B component is water-based alicyclic amine curing agent STW-703B;

[0055] The preparation method of described waterborne anticorrosion paint, comprises the steps:

[0056] (1) Refining stage: Add wetting and dispersing agent, neutralizer, defoamer and part of deionized water into the dispersion tank, disperse at low speed (400r / min) for 8min, then add kaolin and talc Powder and precipitated barium sulfate were dispersed at high speed (1200r / min) for 15 minutes. After the dispersion was completed, transfer to a sand mill for grinding until the fineness was ≤40 μm to obtain mixture I;

[0057] (2) Paint let-down stage: Add the water-based fluorocarbon emulsion, water-based silane emulsion and water-based epoxy emulsion of the water-based anti-corrosion coating into the dispersion ta...

Embodiment 3

[0060] A kind of water-based anticorrosion paint, comprises A component and B component, wherein, described A component comprises following component by weight:

[0061]

[0062]

[0063] The B component is water-based alicyclic amine curing agent EPIKURET M6870-W-53;

[0064] The preparation method of described waterborne anticorrosion paint, comprises the steps:

[0065] (1) Refining stage: Add wetting and dispersing agent, neutralizer, defoamer and part of deionized water into the dispersion tank, disperse at low speed (500r / min) for 5min, then add kaolin and talc powder and precipitated barium sulfate, and disperse at high speed (1200r / min) for 20 minutes. After the dispersion is completed, transfer to a sand mill for grinding until the fineness is ≤40 μm to obtain mixture Ⅰ;

[0066] (2) Paint let-down stage: Add the water-based fluorocarbon emulsion, water-based silane emulsion and water-based epoxy emulsion of the water-based anti-corrosion coating into the dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com