Transforming anti-corrosion enhanced coating for absorbing environmental corrosive substances

An environmental corrosion and anti-corrosion technology, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, rubber derivative coatings, etc., can solve problems such as difficult to reach the design service life, unsatisfactory anti-corrosion effect, difficult construction, etc., to improve mechanical properties. Performance and anti-corrosion performance, increased chlorine content of resin, effect of dense coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

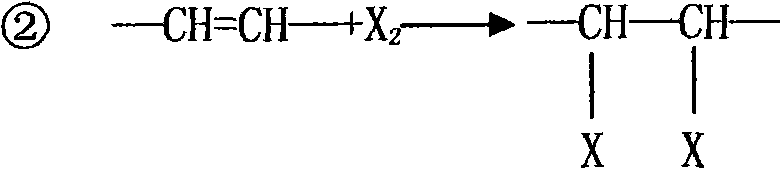

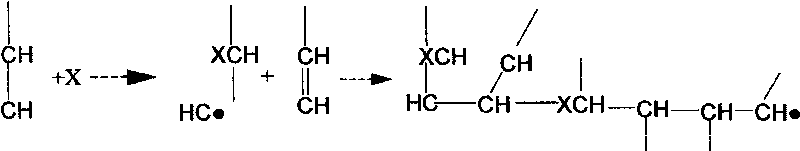

Method used

Image

Examples

Embodiment 1

[0022] Mix 20kg of 50% chlorinated rubber xylene resin solution and 30kg of 50% oleic acid epoxy ester xylene solution with 60% oil, add 10kg of iron-titanium material, 10kg of titanium dioxide, 13kg of precipitated barium sulfate, and disperse at high speed for 1 hour After dispersing evenly, grind until the fineness is less than 25 μm, add the remaining 4.2kg of additives, and stir evenly to prepare the finished anti-corrosion enhanced coating for absorbing environmental corrosive substances.

Embodiment 2

[0024] Acrylic resin 10kg, perchloroethylene resin 20kg, octyl maleate 5kg, 6101 epoxy diacrylate 20kg, put into 10kg xylene respectively, butyl acetate 5kg, cyclohexanone 5kg, stir to dissolve completely, under low stirring Add 15kg of mica iron oxide red and 20kg of talcum powder respectively, stir at high speed for 1 hour, grind to a fineness of less than 30μm, add 3.2kg of additives, and stir evenly to obtain a finished product that absorbs environmental corrosive substances and transforms into an anti-corrosion enhanced coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com