Recycling method for zinc dross

A technology of zinc scum and rough zinc, which is applied in the field of wet zinc smelting, can solve the problems of large zinc loss, high investment cost, and large amount of acid and alkali, and achieve the effect of increasing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

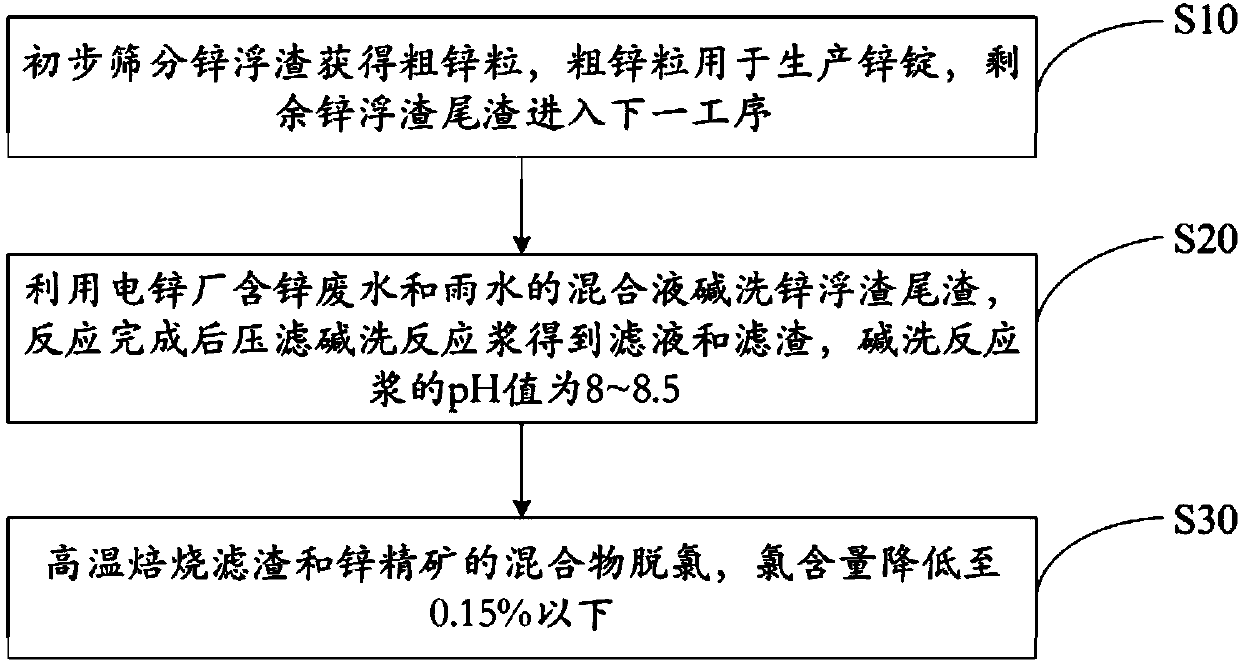

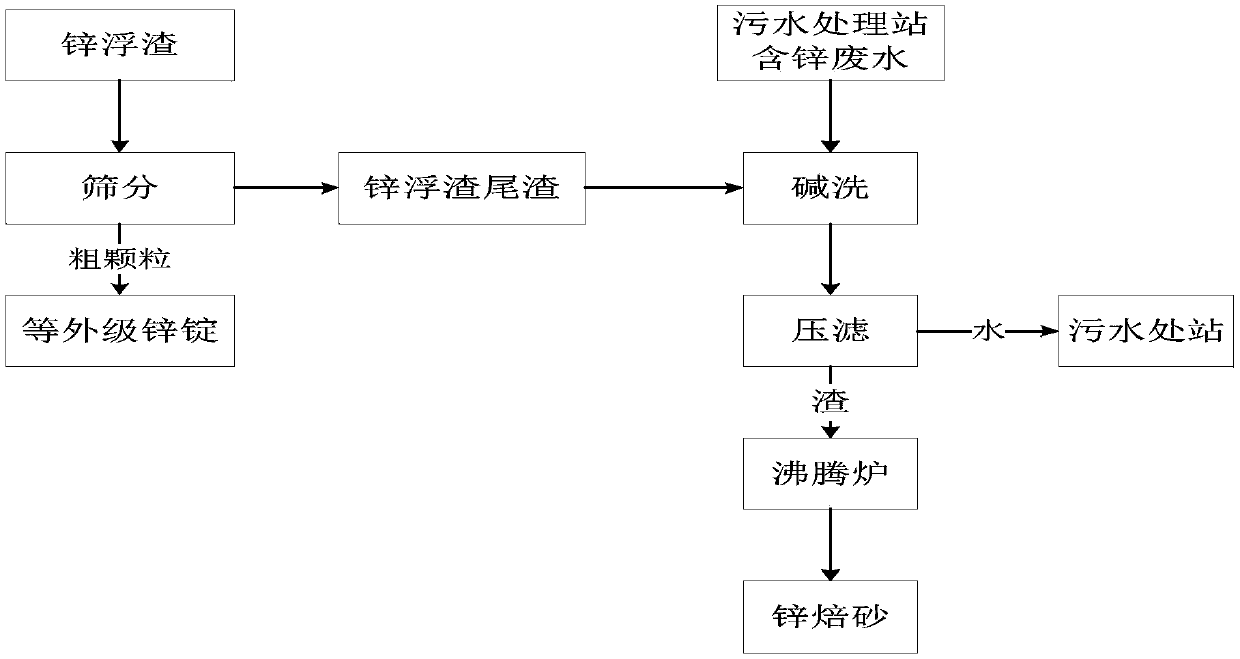

Method used

Image

Examples

Embodiment 1

[0043] Add zinc scum with a chlorine content of 2.352%, a zinc content of 74.46%, and a weight of 4 tons to the Raymond machine for preliminary screening to obtain 0.8 tons of coarse zinc particles and 3.10 tons of zinc scum tailings, and 1.5 tons of zinc scum Add tailings to 18m 3 Add 15 cubic meters of zinc-containing waste water (zinc-containing 165mg / L) and rainwater mixed solution and 40 kg of sodium carbonate in the mixing tank, stir at normal temperature, the stirring speed is 60r / min, the pH value of the alkali cleaning reaction slurry is 8.2 , after the reaction time is 1.5 hours, filter residue and filtrate are obtained by pressure filtration, the weight of filter residue is 1.98 tons, the water content is 30%, and the zinc content of filtrate is 43mg / L, which is returned to the sewage treatment station for processing, and the filter residue is added in the zinc concentrate Put them together into a fluidized fluidized furnace and roast to obtain slag, the roasting te...

Embodiment 2

[0045] Put 2.552% chlorine content, 73.46% zinc content, and 4 tons of zinc scum into the Raymond machine for preliminary screening to obtain 0.8 tons of coarse zinc particles and 3.10 tons of zinc scum tailings, and 1.5 tons of zinc scum Add tailings to 18m 3 Add 15 cubic meters of zinc-containing waste water (zinc-containing 165mg / L) and rainwater mixed solution and 40 kg of sodium carbonate in the stirring tank, stir at normal temperature, the stirring speed is 60r / min, the pH value of the alkali cleaning reaction slurry is 8.1 , after the reaction time is 3 hours, filter residue and filtrate are obtained by press filtration, the weight of filter residue is 1.99 tons, the water content is 30%, and the zinc content of filtrate is 42mg / L, which is returned to the sewage treatment station for processing, and the filter residue is added in the zinc concentrate Put them together into a fluidized fluidized furnace and roast to obtain slag, the roasting temperature is 900° C., and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com