Coating material for platinum material in high-temperature environment and preparation method thereof

A high-temperature environment and coating technology, which is applied in the field of platinum material coating materials and its preparation, can solve the problems of increased parts and large losses, and achieve the effects of reducing the number of parts, avoiding unnecessary losses, and reducing oxidation and volatilization losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

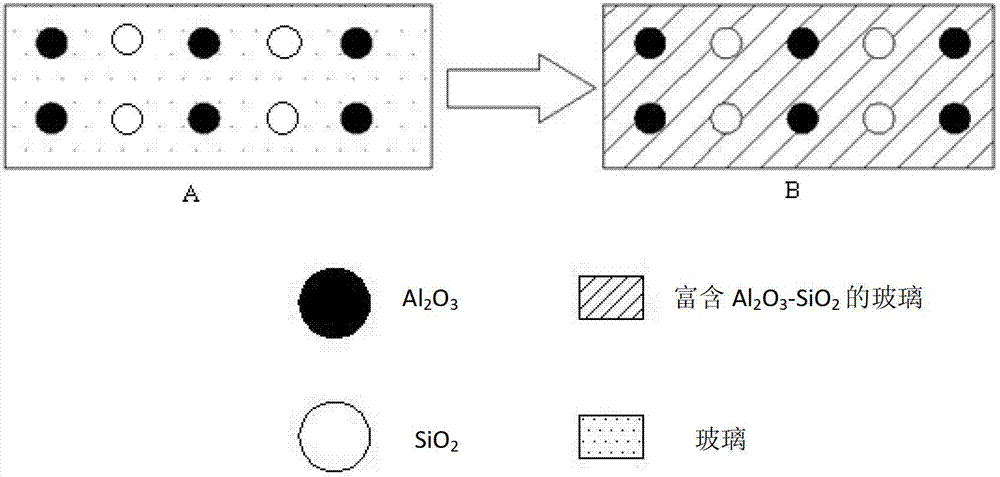

[0024] The coating material of the platinum material used in the high temperature environment of the present invention includes 50% glass powder, 30% alumina particles, 7.5% silica sol, 7.5% silica particles and 5% water according to mass fraction. Glass; wherein the glass powder particle size is less than 30μm, the alumina particle size is less than 20μm, and the silica particle size is less than 100μm.

[0025] The preparation method of the platinum material coating material used in the high temperature environment is: mixing glass powder, alumina particles and silica particles and sintering at 1250°C, then pulverizing the obtained sintered body, and then pulverizing the obtained sintered body Silica sol and water glass are added to the particles to form a coating material for platinum materials used in a high temperature environment; wherein the size of the crushed particles is less than 80 μm.

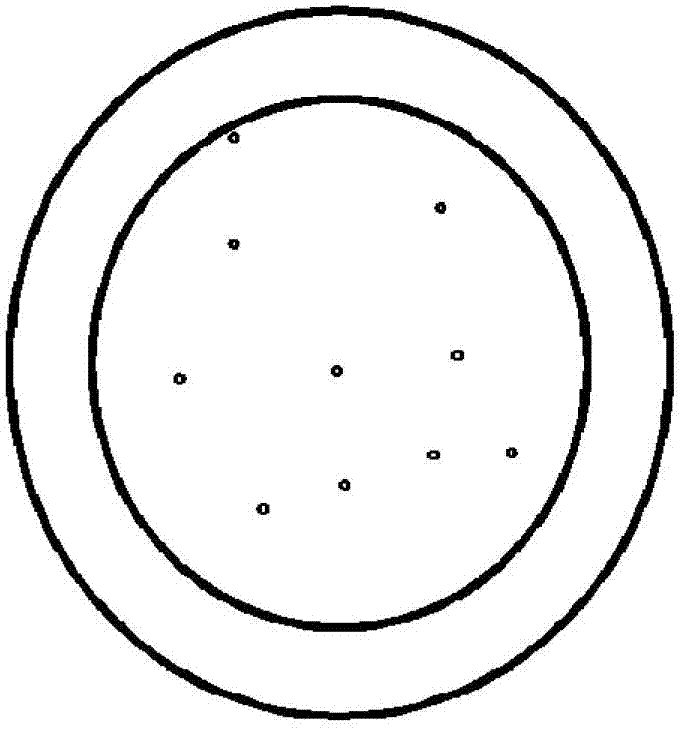

[0026] The coating material of the platinum material used in the high temperature e...

Embodiment 2

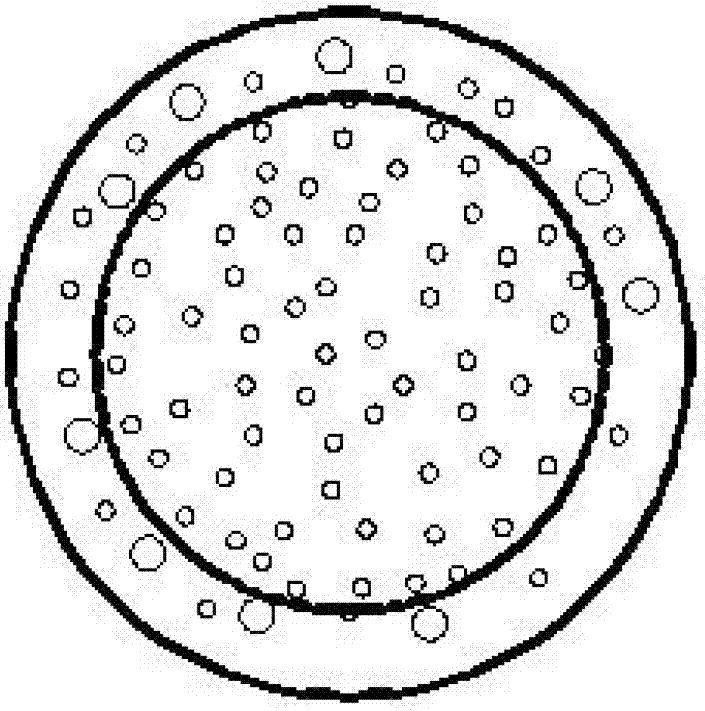

[0028] The coating material of the platinum material used in the high temperature environment of the present invention includes 80% glass powder, 8% alumina particles, 2% alumina fibers, 5% silica sol, and 5% dioxide by mass fraction. Silicon particles; wherein the glass powder particle size is less than 100μm, the alumina particle size is less than 95μm, the silica particle size is less than 80μm, the diameter of the alumina fiber is 20-60μm, and the length is 100-200μm.

[0029] The preparation method of the platinum material coating material used in the high temperature environment is: mixing glass powder, alumina particles and silica particles and sintering at 1320°C, then pulverizing the obtained sintered body, and then pulverizing the obtained sintered body. Silica sol and alumina fibers are added to the particles to form a coating material for platinum materials used in a high-temperature environment; wherein the size of the crushed particles is less than 50 μm.

[0030] The...

Embodiment 3

[0032] The coating material of the platinum material used in the high temperature environment of the present invention includes 60% glass powder, 10% alumina particles, 7% alumina fiber, 20% silica sol and 3% water glass according to mass fraction. Wherein, the glass powder particle size is less than 100μm, the alumina particle size is less than 100μm, the diameter of the alumina fiber is 20-60μm, and the length is 100-200μm.

[0033] The preparation method of the platinum material coating material used in the high temperature environment is: mixing glass powder and alumina particles and sintering at 1600°C, then pulverizing the obtained sintered body, and then adding silica sol to the obtained pulverized particles , Water glass and alumina fiber, that is, the coating material made of platinum material used in high temperature environment; among them, the size of crushed particles is less than 100μm.

[0034] The coating material of platinum material used in the high temperature en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com