Ultraviolet curing coating composition for tectorial color steel plate

A technology for curing coatings and color steel plates, which is applied in the direction of polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., which can solve the problems of film surface dullness, performance that cannot fully meet the needs, fine cracks, etc., and achieve adhesion fastness Outstanding, excellent adhesion fastness, good flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

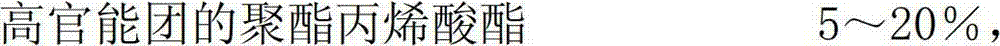

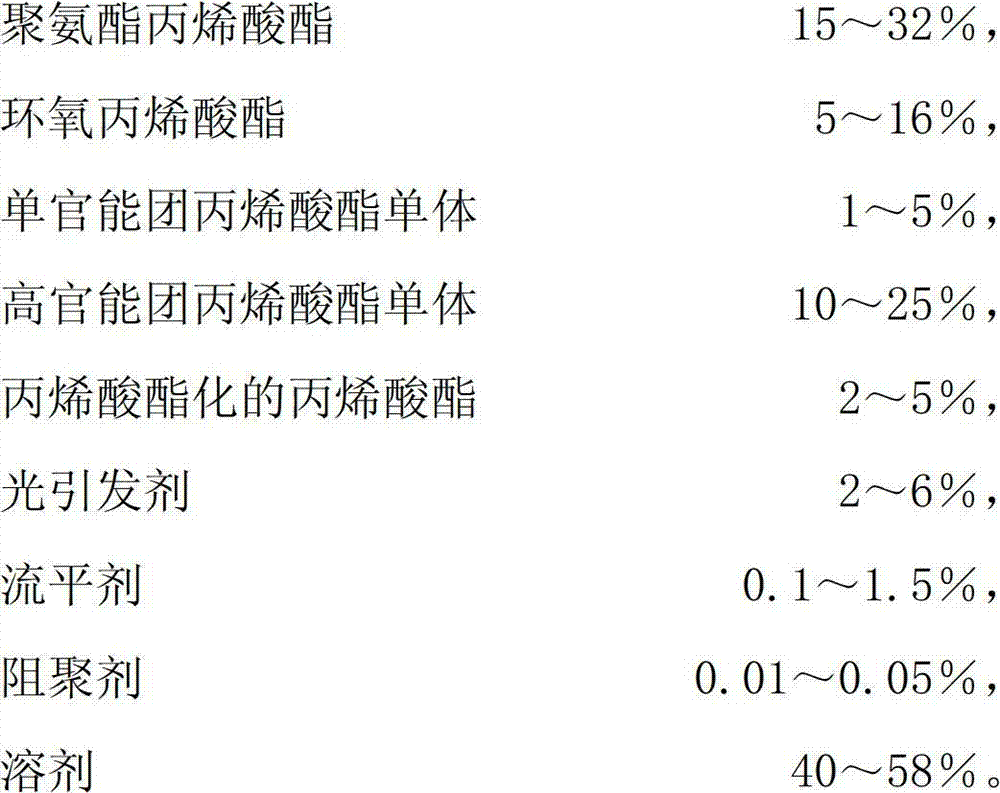

Method used

Image

Examples

Embodiment 1

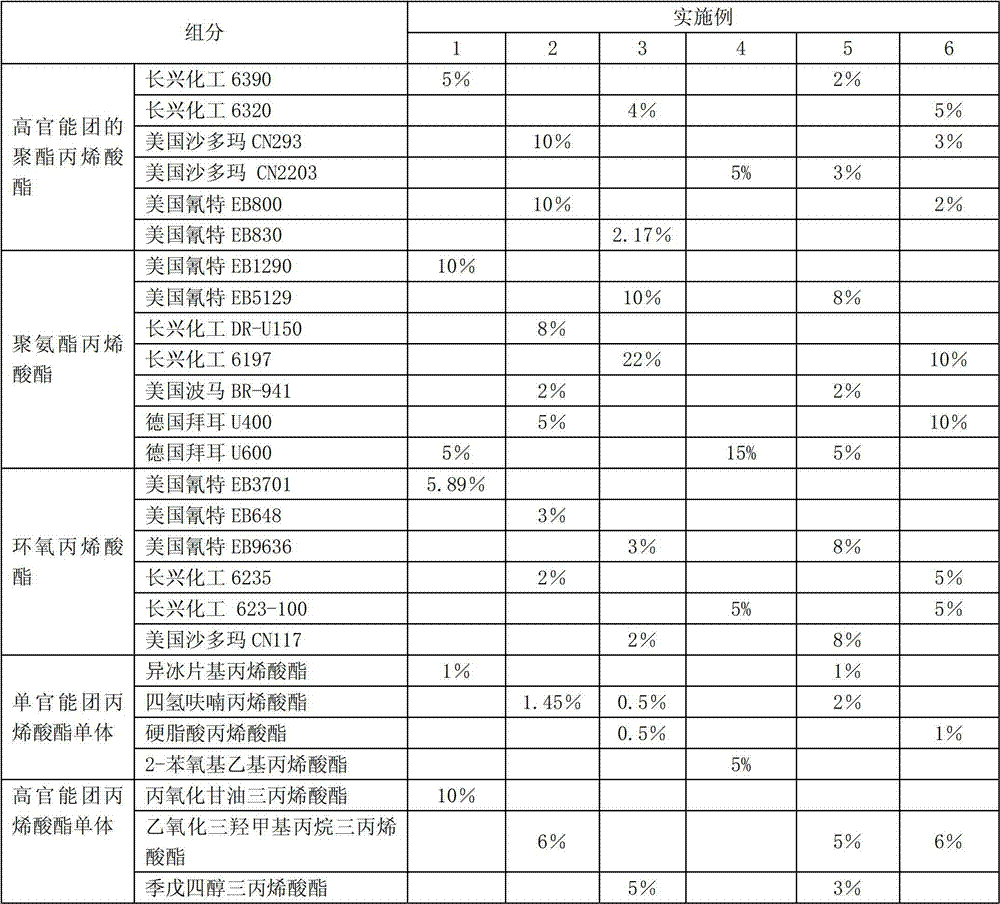

[0034] The UV-curable coating composition for coated color steel plate in this embodiment includes the components in the weight percentages shown in Table 1.

[0035] The coating composition is roll-coated on the PET film, and the coating dry weight is 3-5g / m 2 Between, 65 ℃ infrared leveling for 1 to 2 minutes, the leveling effect is better, after 500mj / cm 2 After the energy is cured, the adhesion fastness between the coating and the PET film is good (100 / 100), the temperature resistance is about 240°C, there is no crack after thermal shock, the organic solvent is resistant to rubbing for 100 times without change, and the surface is resistant to steam for 1 hour. Change, excellent overall performance.

Embodiment 2

[0037] The UV-curable coating composition for coated color steel plate in this embodiment includes the components in the weight percentages shown in Table 1.

[0038] Apply the coating roller to the PET film, the coating dry weight is 3~5g / m 2 Between, 65 ℃ infrared leveling for 1 to 2 minutes, the leveling effect is better, after 500mj / cm 2 After the energy is cured, the adhesion between the coating and the PET film is good (100 / 100). , excellent overall performance.

Embodiment 3

[0040] The UV-curable coating composition for coated color steel plate in this embodiment includes the components in the weight percentages shown in Table 1.

[0041] Apply the coating roller to the PET film, the coating dry weight is 3~5g / m 2 Between, 65 ℃ infrared leveling for 1 to 2 minutes, the leveling effect is better, after 500mj / cm 2 After the energy is cured, the adhesion between the coating and the PET film is good (100 / 100). , excellent overall performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com