Preparation of flexible high-resistance multi-layer transparent conductive film

A transparent conductive film, high-resistance technology, applied to conductive layers, coatings, layered products on insulating carriers, etc., can solve the problems of unstable resistance of ITO high-resistance films, short production process flow, and high production efficiency. The film layer is dense, the service life is improved, and the service life is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The inventive method comprises:

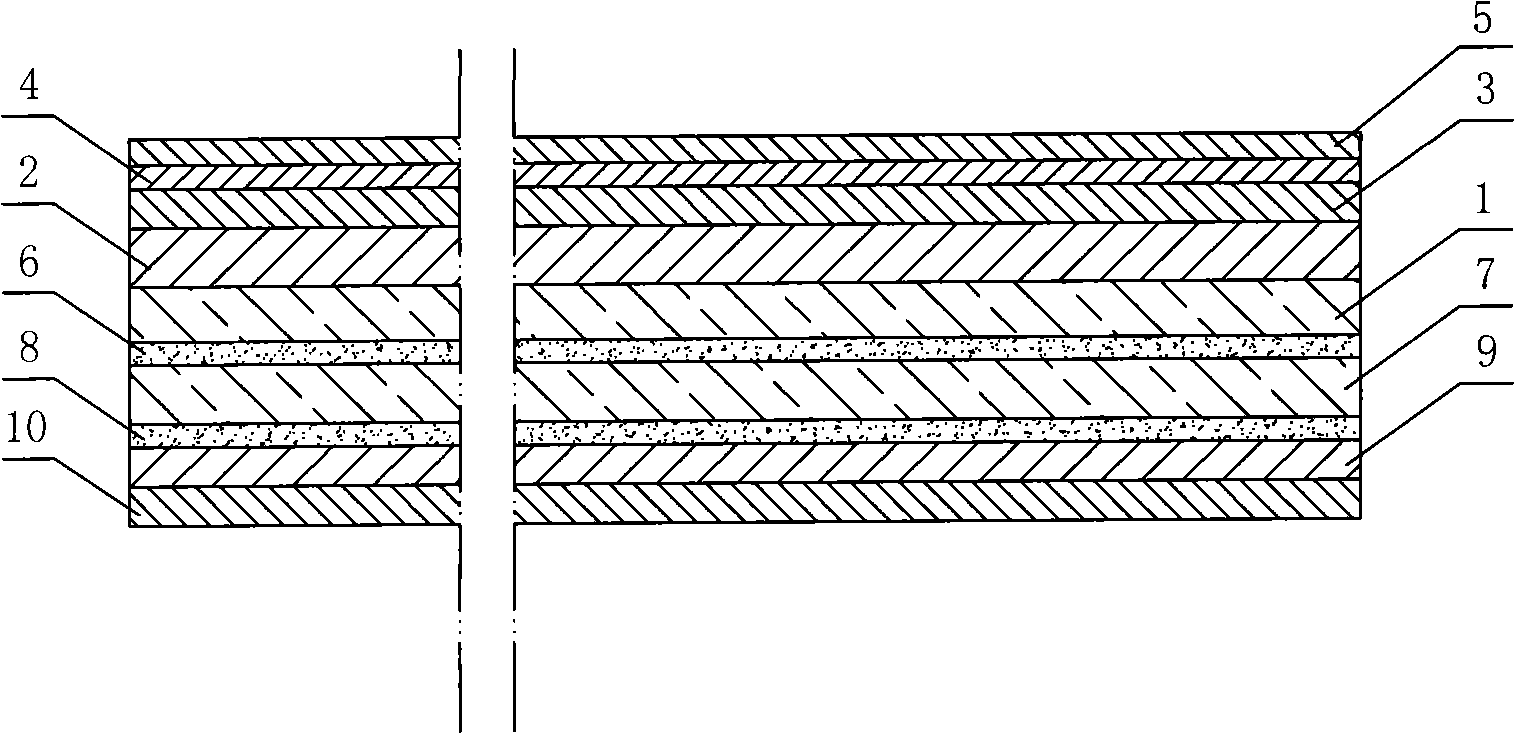

[0021] Using intermediate frequency magnetron sputtering technology to successively form titanium dioxide layer 2, silicon dioxide layer 3, indium tin oxide layer 4, zinc aluminum oxide layer or zinc gallium oxide layer 5 on one side of the flexible substrate PET polyester film 1 In the film-forming process of indium tin oxide layer 4, utilize the heat energy that high-energy particles continuously bombard and deposit on PET polyester film 1 when aforementioned titanium dioxide layer 2 and silicon dioxide layer 3 intermediate-frequency magnetron sputtering film-forming, Make the temperature reach 120°C or higher, and control the oxygen-indium atomic ratio (O / In) in the range of 1.26-1.29, so as to obtain the indium tin oxide layer 4 with a crystalline structure;

[0022] The other side of the flexible substrate PET polyester film 1 is bonded to one side of the second layer of PET polyester film 7 through the adhesive layer 6, and a hard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com