Single-component exposed acrylic acid modified polyurethane waterproof paint and preparation method

A polyurethane waterproof and acrylate technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as pinholes, cracking, construction performance, and low strength, and prevent excessive molecular weight, dense and seamless coatings, The effect of good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

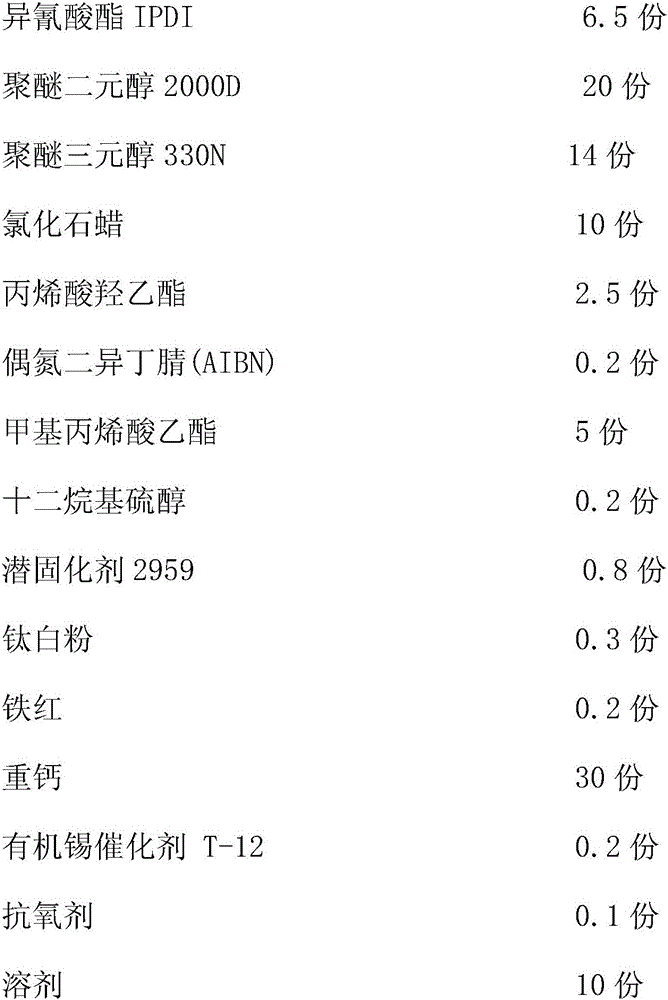

[0022] 1. Raw material ratio of modified polyurethane waterproof coating:

[0023]

[0024] 2. Process of modified polyurethane waterproof coating:

[0025] (1) Add 20 parts by weight of polyether diol 2000D, 14 parts by weight of polyether trihydric alcohol 330N, 10 parts by weight of chlorinated paraffin and 30 parts by weight of heavy calcium, 0.3 parts by weight of titanium dioxide, and 0.2 parts by weight of iron red in the reaction vessel. parts, respectively, stirred and heated to 100°C-120°C, and dehydrated for 2-3 hours under the condition of vacuum of -0.01MPa;

[0026] (2) Lower the temperature to 60°C to 80°C, add 6.5 parts by weight of isocyanate IPDI, and react for 1 to 2 hours under stirring at 80°C;

[0027] (3) Cool down to 60°C, add 2.5 parts by weight of hydroxyethyl acrylate, heat up to 70°C and react for 2 to 3 hours; then maintain the temperature at 70°C, add 0.2 parts by weight of initiator azobisisobutyronitrile (AIBN) , 0.2 parts by weight of chai...

Embodiment 2

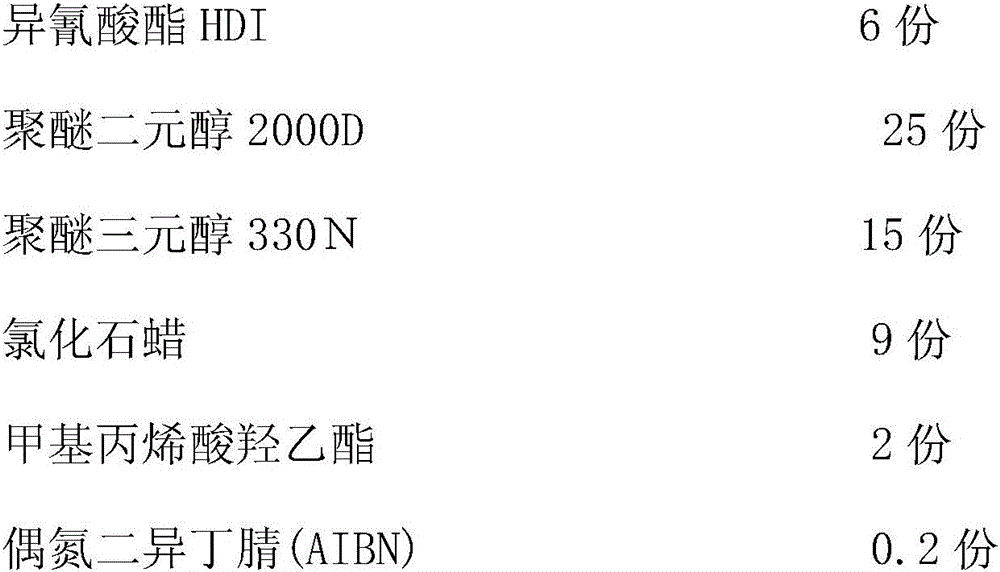

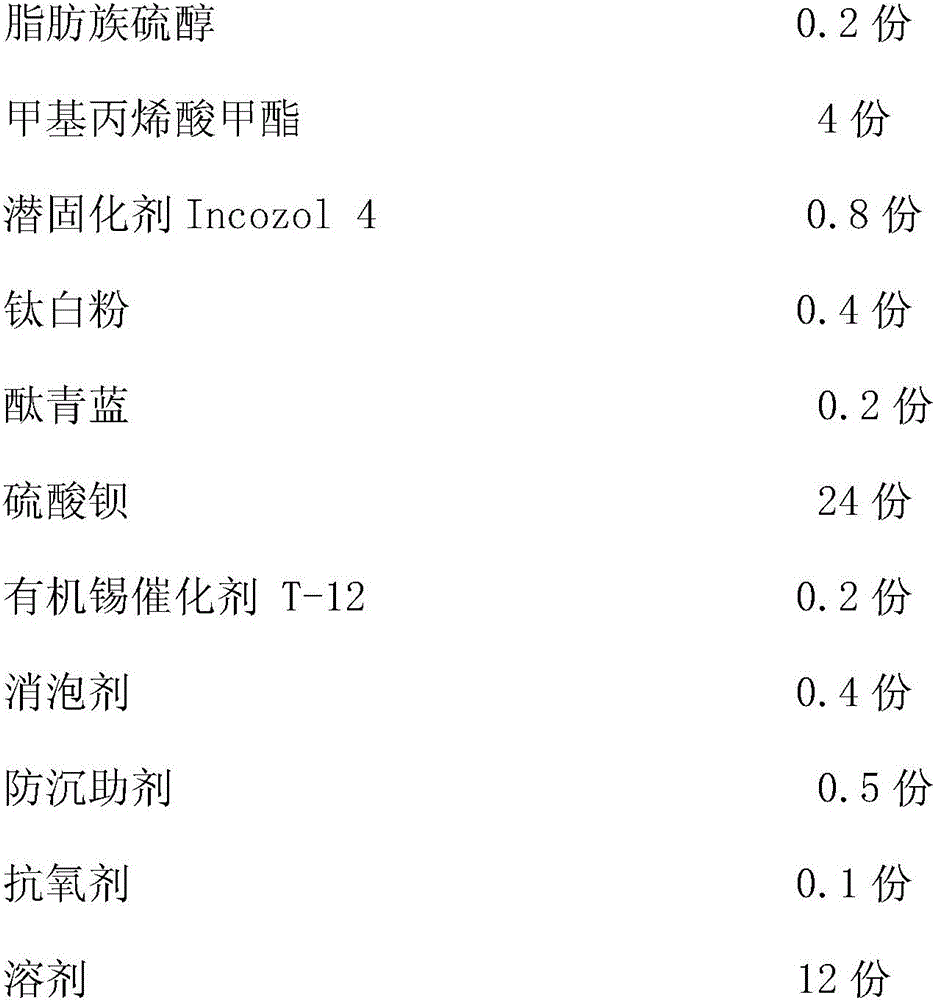

[0031] 1. Raw material ratio of modified polyurethane waterproof coating:

[0032]

[0033]

[0034] 2. Process of modified polyurethane waterproof coating:

[0035] (1) Add 25 parts by weight of polyether diol 2000D, 15 parts by weight of polyether trihydric alcohol 330N, 9 parts by weight of chlorinated paraffin and 24 parts by weight of barium sulfate, 0.4 parts by weight of titanium dioxide, and phthalocyanine blue 0.2 weight, stir separately and heat up to 100 ℃ ~ 120 ℃, dehydration under the condition of -0.01MPa vacuum for 2 ~ 3 hours;

[0036] (2) Lower the temperature to 60°C to 80°C, add 6 parts by weight of isocyanate HDI, and react for 1 to 2 hours under stirring at 80°C;

[0037] (3) Cool down to 60°C, add 2 parts by weight of hydroxyethyl methacrylate, raise the temperature to 70°C for 2-3 hours; then maintain the temperature at 70°C, add 0.2 Parts by weight, chain transfer agent aliphatic mercaptan 0.2 parts by weight, then dropwise add methyl methacrylate...

Embodiment 3

[0041] 1. Raw material ratio of modified polyurethane waterproof coating:

[0042]

[0043]

[0044] 2. Process of modified polyurethane waterproof coating:

[0045] (1) Add 10 parts by weight of polyether diol 2000D, 26 parts by weight of polyether trihydric alcohol 330N, 8 parts by weight of chlorinated paraffin and 21 parts by weight of calcium carbonate, 10 parts by weight of talcum powder, 0.5 parts by weight of titanium dioxide in the reaction vessel Parts by weight, 0.2 parts by weight of bright yellow, respectively stirred and heated to 100°C-120°C, and dehydrated for 2-3 hours under the condition of a vacuum of -0.01MPa;

[0046] (2) Lower the temperature to 60°C-80°C, add 6 parts by weight of isocyanate IPDI, and react for 1 to 2 hours under stirring at 80°C;

[0047] (3) Cool down to 60°C, add 2 parts by weight of hydroxyethyl acrylate, heat up to 70°C and react for 2-3 hours; then maintain the temperature at 70°C, add 0.2 parts by weight of initiator azobisi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com