Surface-modified coating and preparation method and application thereof

A surface modification and coating technology, applied in the field of surface modification coating and its preparation, can solve the problems of lack of biological activity, poor wear resistance, poor osteogenesis performance, etc., and achieve small ion dissolution and good wear resistance , Good effect on early osteogenic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing a surface-modified coating, comprising the steps of:

[0040] S1. Using titanium powder as a raw material, a titanium coating with a porous structure is prepared on the surface of the substrate by plasma spraying;

[0041] S2. Taking Ta as the target material and using oxygen as the reaction gas, a Ta-O coating is prepared on the surface of the porous titanium coating by ion beam sputtering coating method.

[0042] In the step S1, the diameter of the titanium powder is 100-200 μm; the thickness of the obtained titanium coating is 100-500 μm; the substrate is a medical metal material; the metal material is titanium, stainless steel, or cobalt-chromium-molybdenum alloy.

[0043] In the step S1, the process conditions of the plasma spraying are: the working gas Ar flow rate is 35-55 slpm, the H 2 The flow rate is 7-20slpm, the spraying power is 35-60kW, the coating distance is 250-300mm, the spraying power is 30-60kW, and the powder feeding rate is ...

Embodiment

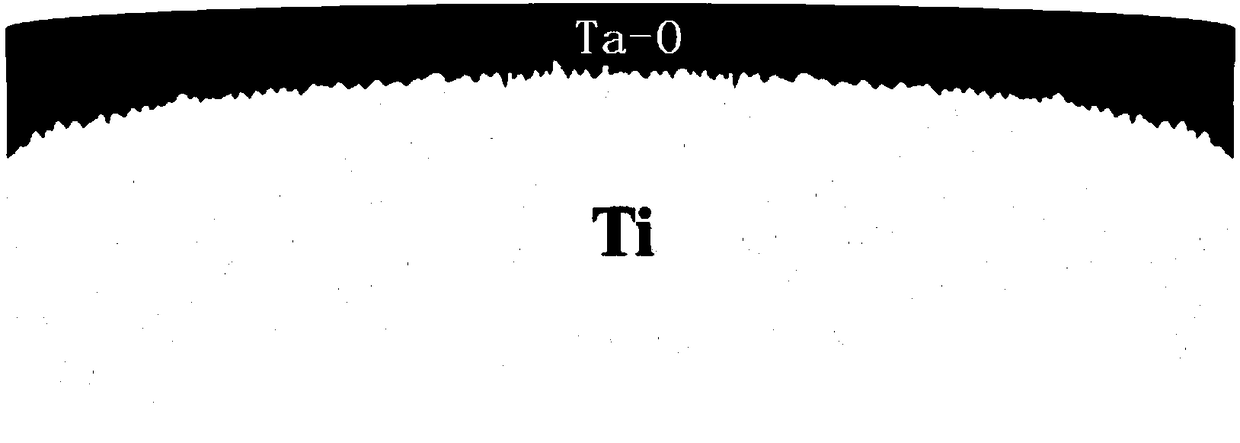

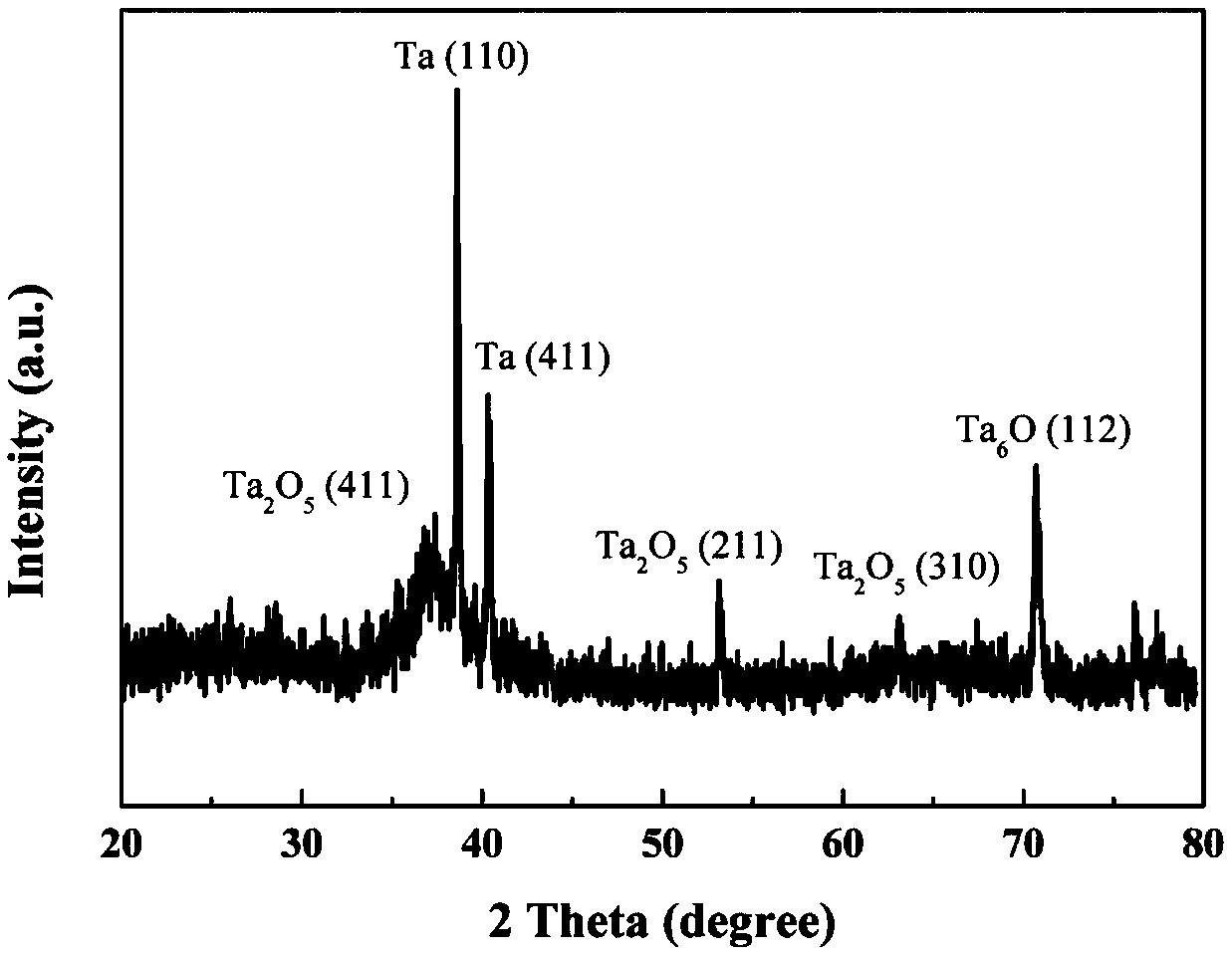

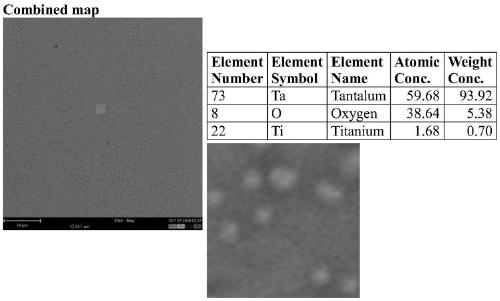

[0048] A kind of surface modification coating of the present invention, schematic diagram is as figure 1 As shown, the substrate is a titanium sheet. From the inside to the outside of the substrate, there is a porous Ti coating and an outer Ta-O layer. The thickness of the porous Ti coating is 100 μm; the thickness of the Ta-O layer is 3 μm . The Ta-O coating is Ta 2 o 5 As well as unoxidized Ta single substance and incompletely oxidized metastable phase oxide. The porosity of the porous Ti coating is 16.7%.

[0049] A preparation method of the surface modified coating of the present embodiment, comprising the steps of:

[0050] S1. Raw material selection and substrate pretreatment:

[0051] Titanium sheets are selected as the base material and processed into small discs of Φ10mm×2mm. After sandblasting the surface of the titanium sheet, ultrasonically clean it once in absolute ethanol solution for 3 minutes, then dry it at 100°C for 1 hour, and cool it for later use; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com