Fabric with small bias filling rate for airbag

A technology of skewness and fabric, which is applied in the directions of fabrics, textiles, textiles and papermaking, can solve the problems of not effectively improving the skewness of fabrics, and cannot reduce the rate of defective cutting, and achieves good elasticity, not easy to become brittle, and soft. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

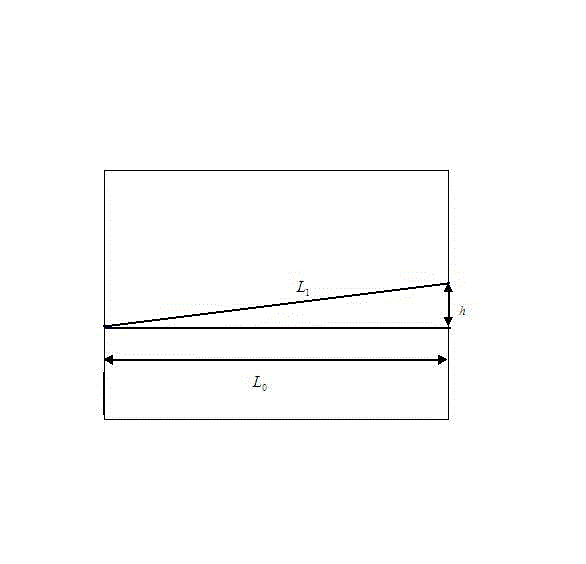

Image

Examples

Embodiment 1

[0039] The texture of the airbag fabric is made of nylon 66 raw yarn with a total fineness of 350dtex, 136 filaments, and a circular cross section. The tensile breaking strength is 8.3cN / dtex, and the tensile breaking elongation is 21.5%. The modulus is 55cN / dtex. The two sides of the fabric for airbags use nylon 66 raw yarn with a total fineness of 350dtex, 136 single filaments, and a circular cross section. The tensile breaking strength is 8.3cN / dtex, and the elongation at break is 20.0%. The amount is 48cN / dtex, and the number of roots is 82. After the plain weave fabric is woven with a rapier loom, the temperature of the scouring tank is 80±5°C, the temperature of the washing tank is 65±5°C, the heat setting temperature is 150±10°C, and the speed is 30 m / min. The all-in-one machine performs post-processing to obtain a fabric with a warp density of 60 threads / inch and a weft density of 60 threads / inch. The characteristics of this base cloth were evaluated and are shown in...

Embodiment 2

[0041] The texture of the airbag fabric is made of nylon 66 raw yarn with a total fineness of 470dtex, 68 single filaments, and a circular cross section. The tensile breaking strength is 8.3cN / dtex, and the tensile breaking elongation is 21.5%. Modulus 60cN / dtex. The fabric on both sides of the airbag fabric is made of nylon 66 raw yarn with a total fineness of 470dtex, 68 single filaments, and a circular cross-section. The tensile breaking strength is 8.3cN / dtex, and the tensile elongation at break is 21.5%. Modulus 45cN / dtex. The root number is 50. After the plain weave fabric is woven with a rapier loom, the temperature of the scouring tank is 80±5°C, the temperature of the washing tank is 65±5°C, the heat setting temperature is 170±10°C, and the speed is 30 m / min. The all-in-one machine performs post-processing to obtain a fabric with a warp density of 49.5 threads / inch and a weft density of 49.5 threads / inch. The characteristics of this base cloth were evaluated and ar...

Embodiment 3

[0043] The airbag fabric is made of raw polyester yarn with a total fineness of 700dtex, 105 filaments, and a circular cross-section. The tensile breaking strength is 8.0cN / dtex, and the tensile elongation at break is 21.5%. The amount is 65cN / dtex. Both sides of the fabric for airbags are made of raw polyester yarn with a total fineness of 700dtex, 105 single filaments, and a circular cross-section. The tensile breaking strength is 8.0cN / dtex, and the tensile elongation at break is 23.0%. The modulus is 40cN / dtex, and the number of roots is 40. After the plain weave fabric is woven with a rapier loom, the temperature of the scouring tank is 80±5°C, the temperature of the washing tank is 65±5°C, the heat setting temperature is 180±10°C, and the speed is 30 m / min. The all-in-one machine performs post-processing to obtain a fabric with a warp density of 41 threads / inch and a weft density of 41 threads / inch. The characteristics of this base cloth were evaluated and are shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com