Patents

Literature

75results about How to "Not easy to fold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

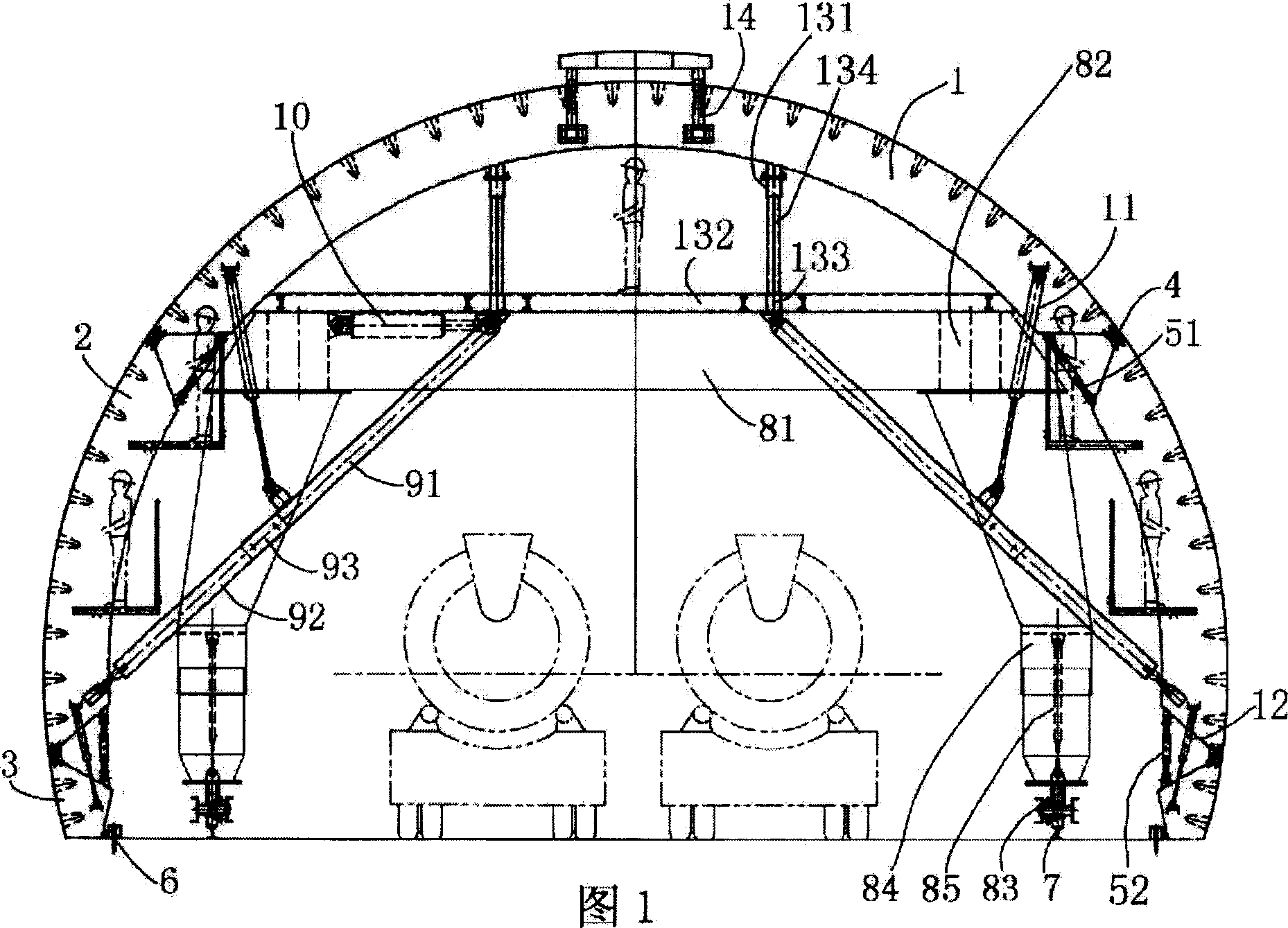

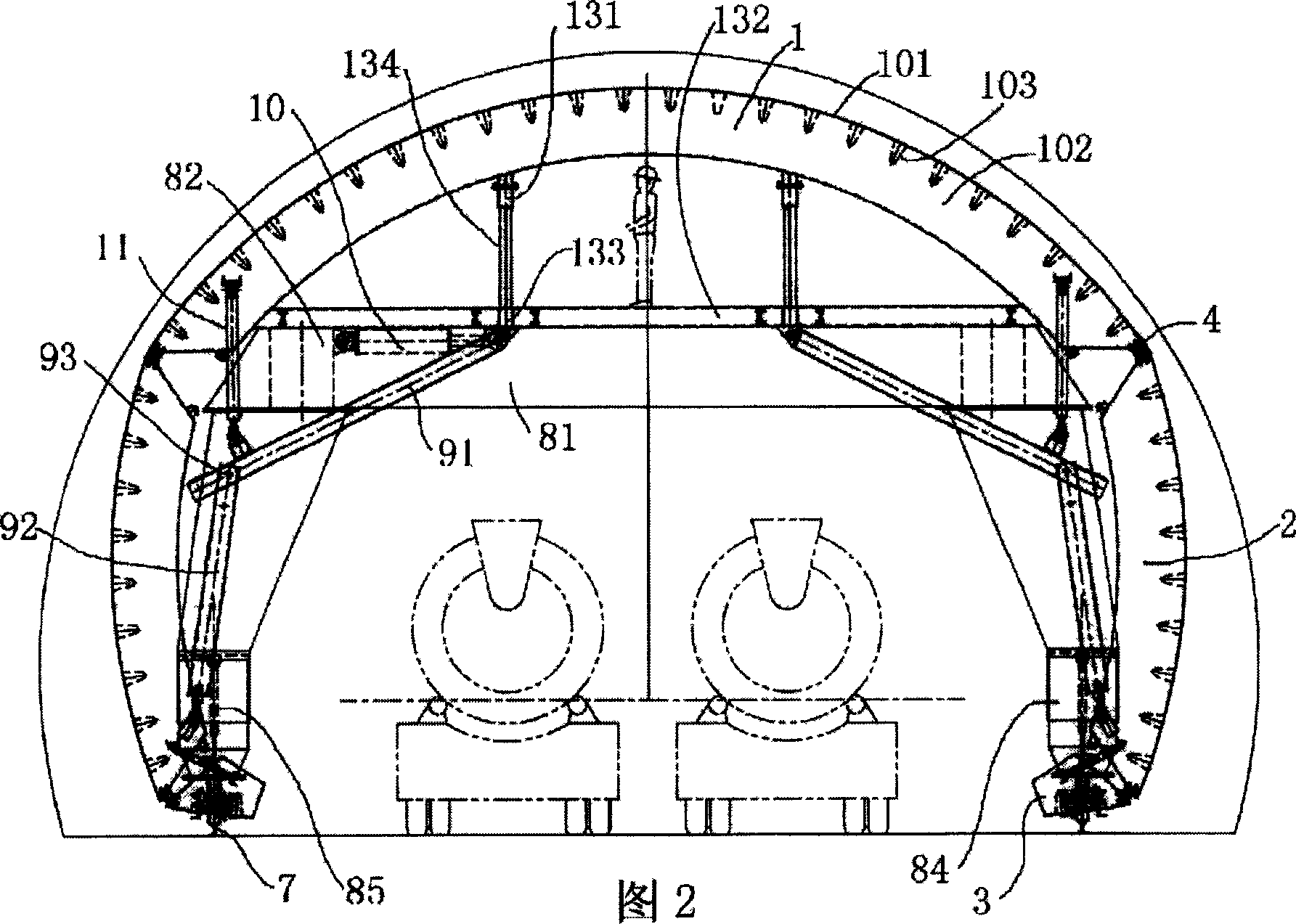

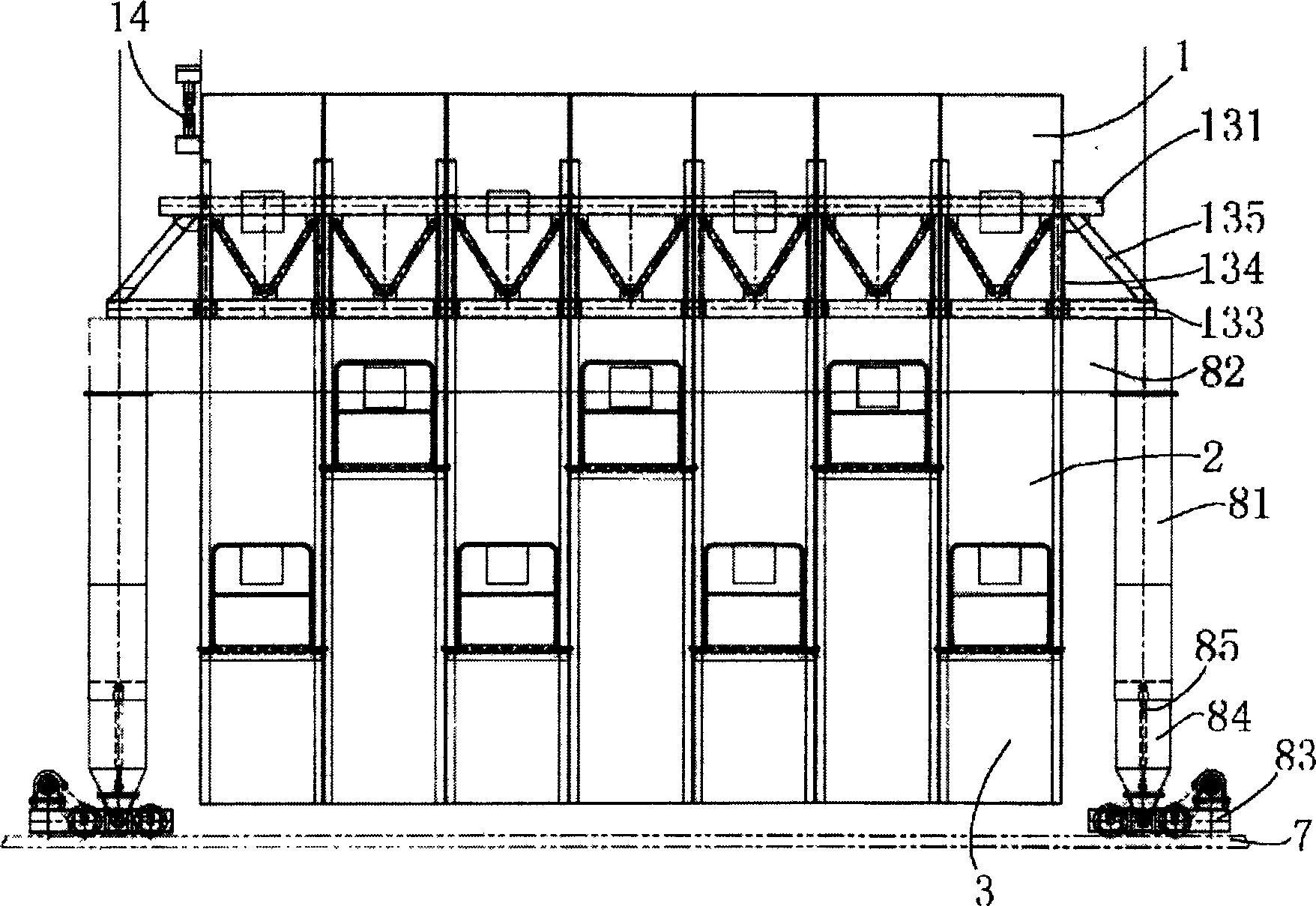

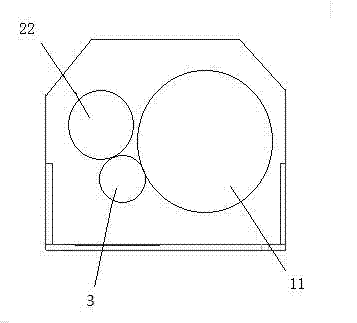

Tunnel lining trolley

InactiveCN1851233AFrame widthIncrease stiffnessUnderground chambersTunnel liningEngineeringMechanical engineering

The invention is a tunnel lining carrier, where a group of templates comprises top plate, two side templates and two bottom templates, the cross sections at the interfaces between the top template and the two side templates and between the two side templates and the two bottom templates are horn-shaped, and their outer edges are hinged with flat top hinge and their inner edges are connected with regulating screws; a template bracket comprises top longitudinal beam, cross beam, bottom longitudinal beam, column and inclined strut. And the carrier comprises door frame, girder summer and moving system; folding supports arms are connected between the bottom surface of the crossbeam and the bottom ends of the two side templates, side moving hydraulic oil cylinder is connected between the bottom longitudinal beam and the girder summer, expanding hydraulic oil cylinders are connected between the large arms of the folding support arms and the two bottom ends of the top template, and opening hydraulic oil cylinders are connected in the horn-shaped positions between the side and bottom templates.

Owner:杨秋利

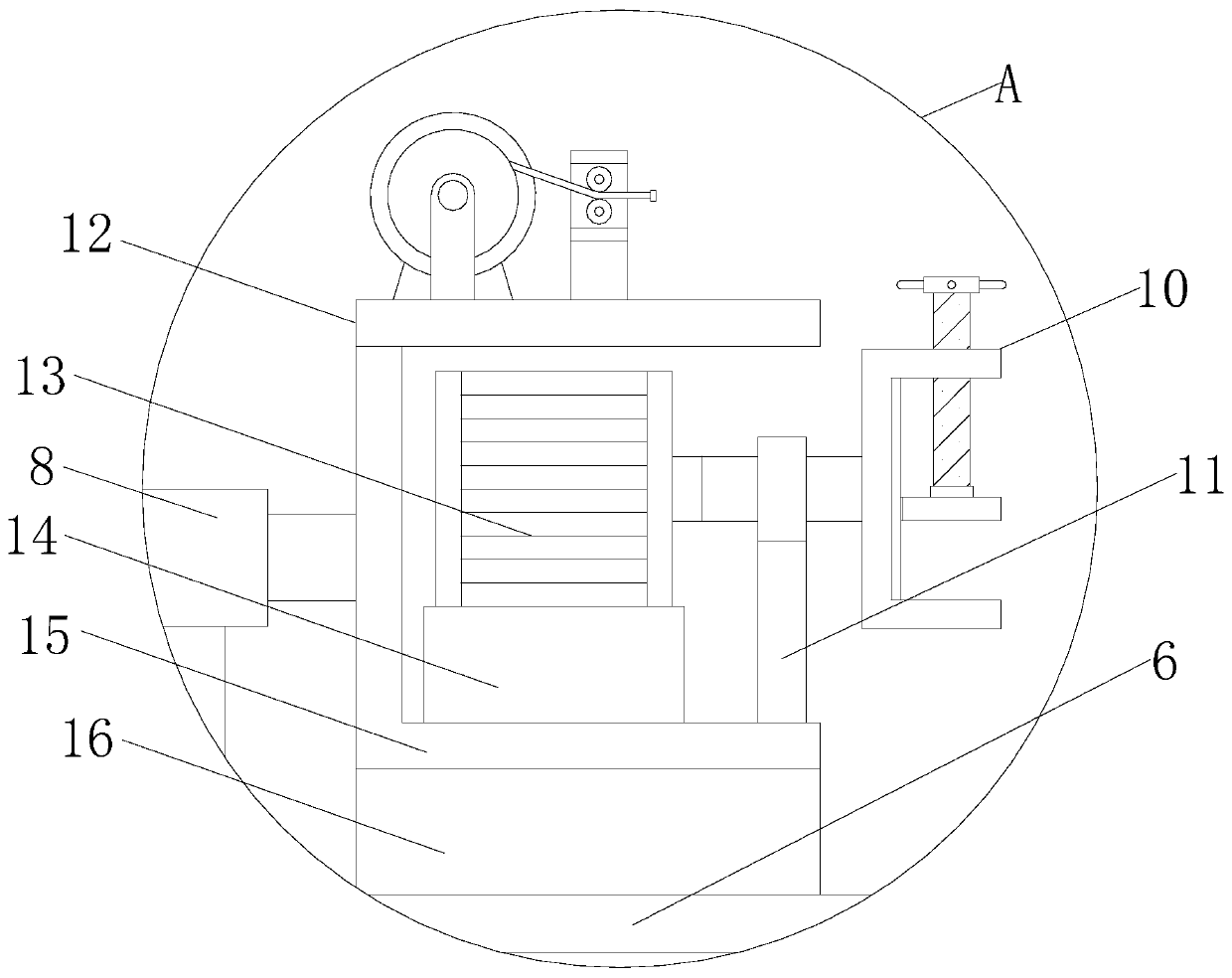

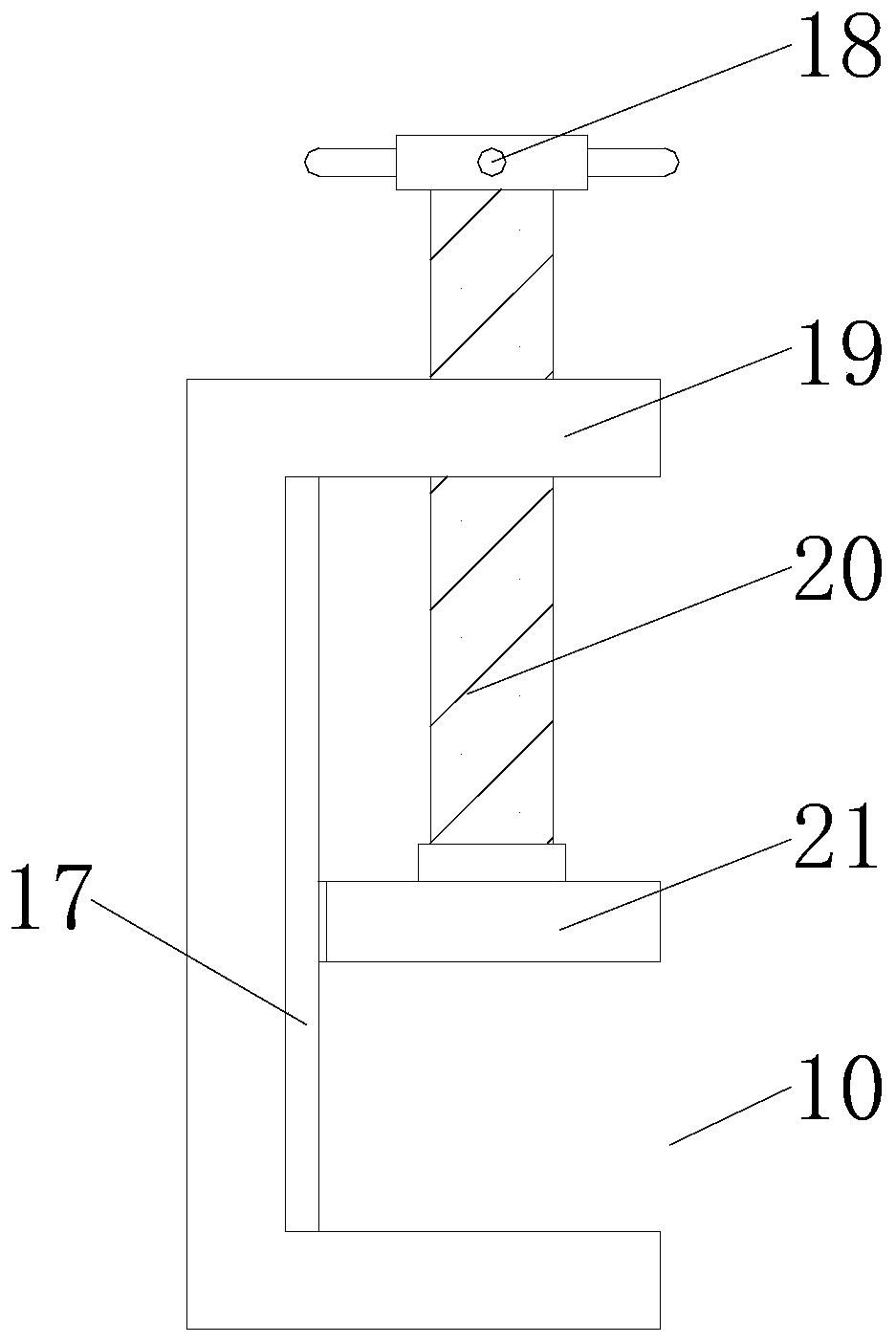

Fixing device facilitating machining of aluminum plate

InactiveCN110893554AEasy to installEasy to disassembleMeasurement/indication equipmentsWork benchesStructural engineeringThreaded rod

The invention discloses a fixing device facilitating machining of an aluminum plate, and relates to the technical field of aluminum plate machining. The fixing device comprises a box body, first threaded rods are rotatably mounted at the two sides of the interior of the box body through bearings, sliding rods are fixedly mounted at the two sides of the interior of the box body, and stop blocks arefixedly mounted at the tops of the sliding rods respectively. According to the fixing device, a first cushion block, an electric telescopic rod, a clamping mechanism, an L-shaped frame, a connectingsliding block, a sliding rail, a handle, mounting frames, a second threaded rod and a pressing plate are matched for use; the aluminum plate is clamped between the two mounting frames and is fixed less difficultly; the pressing plate can be moved up and down to be adjusted so that the top of clamps the aluminum plate; and the fixing stability of the aluminum plate is improved, the aluminum plate is prevented from falling accidentally, and the operation stability and safety of the device are improved.

Owner:湖州华利铝业有限公司

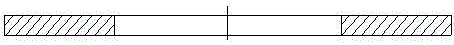

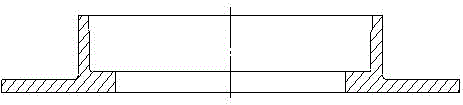

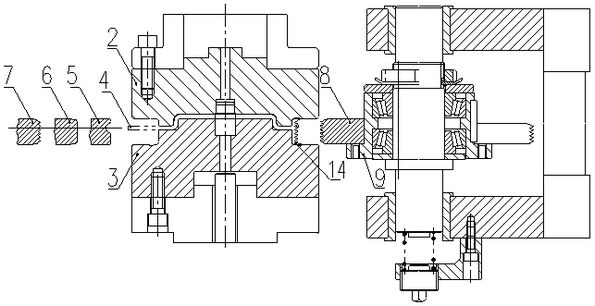

Automobile crankshaft thickened hub multi-wedge wheel forming technique and tool

The invention discloses an automobile crankshaft thickened hub multi-wedge wheel forming technique and tool. The whole machining process is completed through blanking and punching, shovel spinning formation, stamping formation of arcs and rotary tooth thickening sequentially. A rotary tooth thickening tool for rotary tooth thickening comprises an upper die, a lower die, a positioning core, a cover plate, an unloading plate, an arc rotary wheel, a first pre-spinning wheel, a second pre-spinning wheel and a final formation rotary wheel, wherein the arc rotary wheel, the first pre-spinning wheel, the second pre-spinning wheel and the final formation rotary wheel are used in cooperation sequentially. The automobile crankshaft thickened hub multi-wedge wheel forming technique and tool have the advantages that the machining process is stable, the spinning effect is good, material folding, layering and cracking are not prone to occurring in the forming process, the purpose of integrated formation is achieved, finished products are more stable and firm in structure, and meanwhile the service life is prolonged; and the adopted rotary tooth thickening tool is simple in structure, an obtained pulley groove is smooth in surface and high in precision, the service life of matching belts is prolonged, and meanwhile the production efficiency of products is improved.

Owner:NANTONG FULEDA AUTOMOBILE FITTINGS

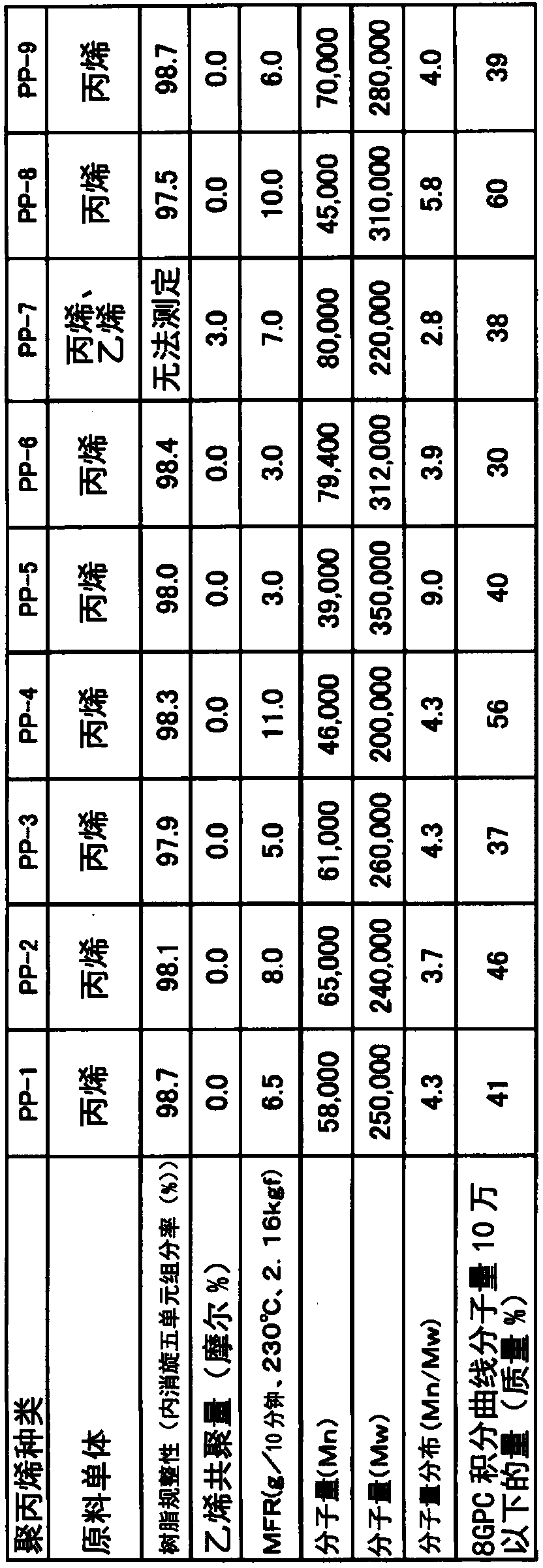

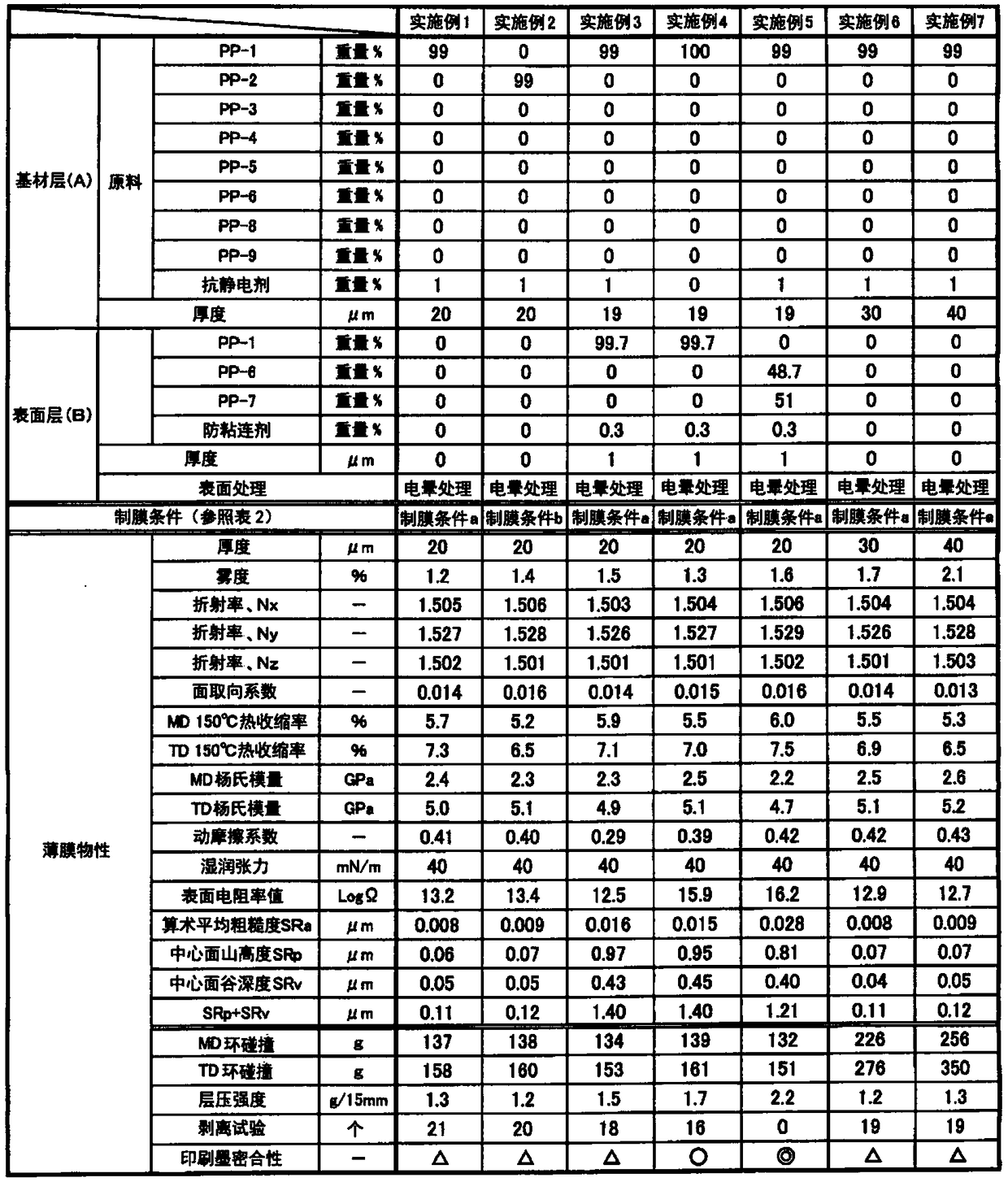

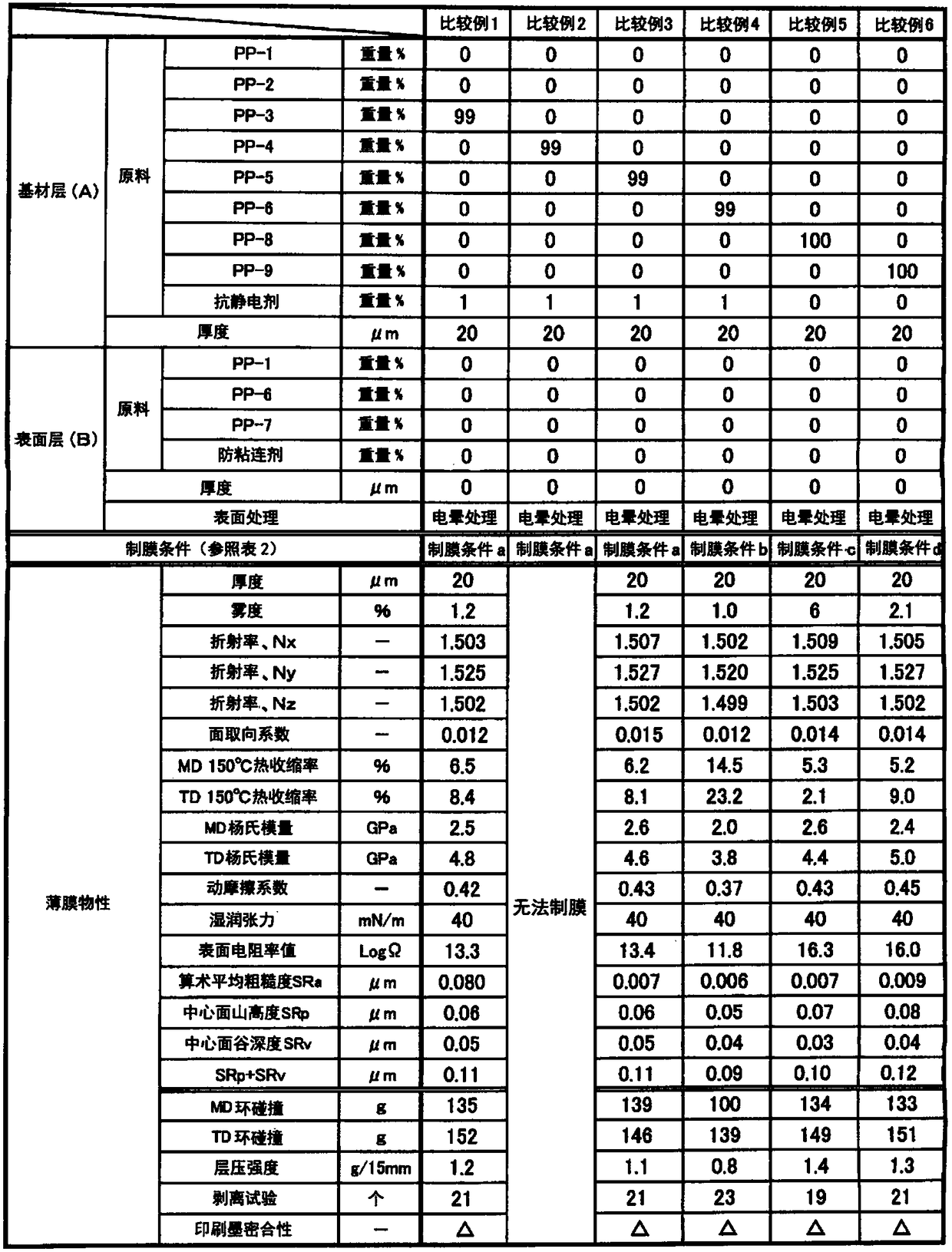

Biaxially oriented polypropylene film

PendingCN108884246ASmall molecular weight distributionReduce tanglesSynthetic resin layered productsThin membranePolypropylene

In order to provide a biaxially stretched polypropylene film having higher thermal resistance and rigidity, this biaxially oriented polypropylene film is characterized by: a polypropylene resin constituting the film fulfilling conditions 1)-4); and the lower limit of a plane orientation coefficient for the film being 0.0125. 1) The mesopentad fraction lower limit being 96%. 2) The upper limit forthe amount of copolymerized monomers other than propylene being 0.1 mol%. 3) Mass average molecular weight (Mw) / number average molecular weight (Mn) being 3.0-5.4. 4) The melt flow rate (MFR) measuredat 230 DEG C and 2.16 kgf being 6.2-9.0 g / 10 min.

Owner:TOYO TOYOBO CO LTD

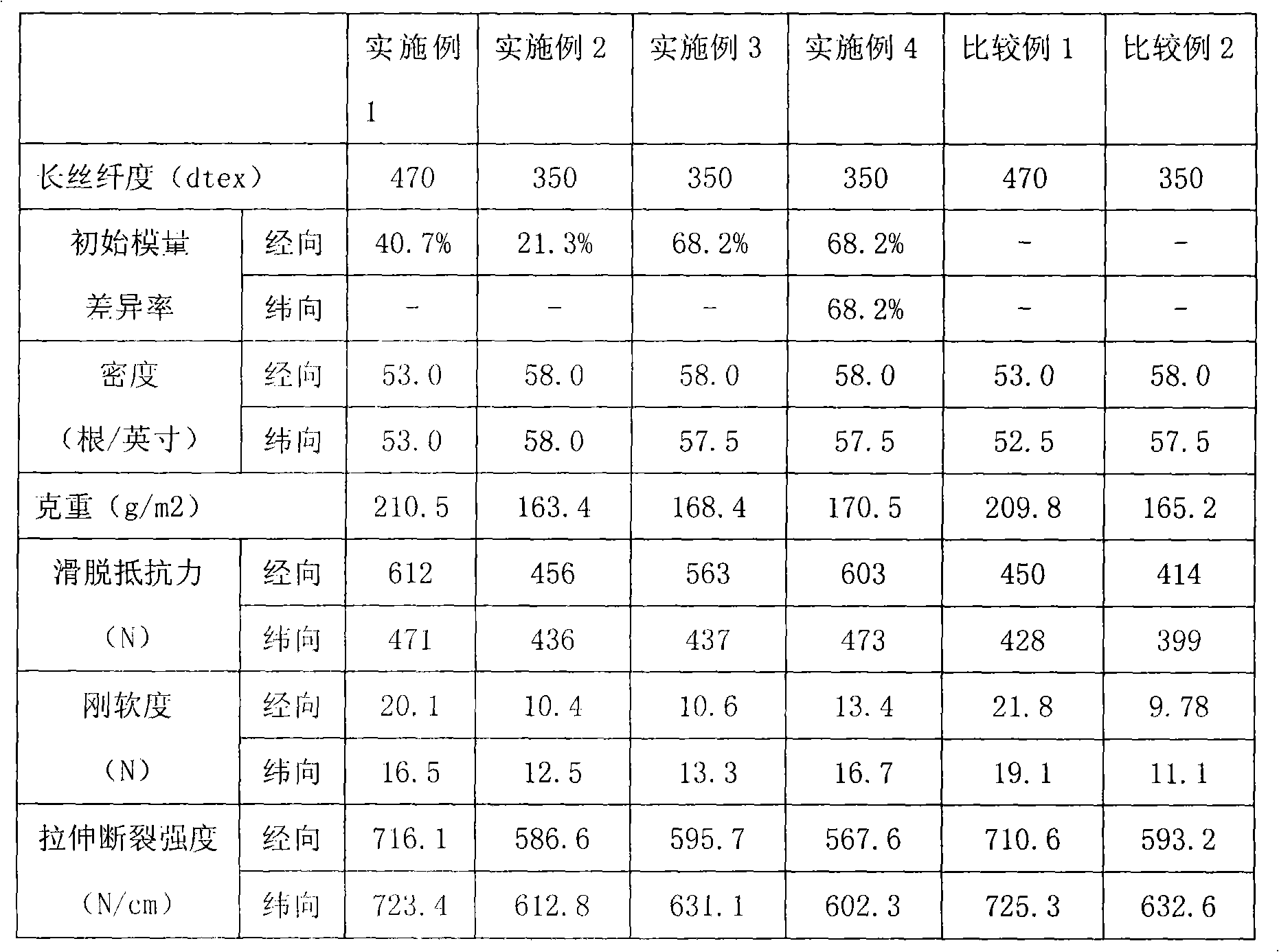

Fabric for safety air bag

InactiveCN101666007AImprove slip resistanceModerate stiffnessPedestrian/occupant safety arrangementWoven fabricsEngineeringAirbag

Owner:TORAY FIBER RES INST(CHINA) CO LTD

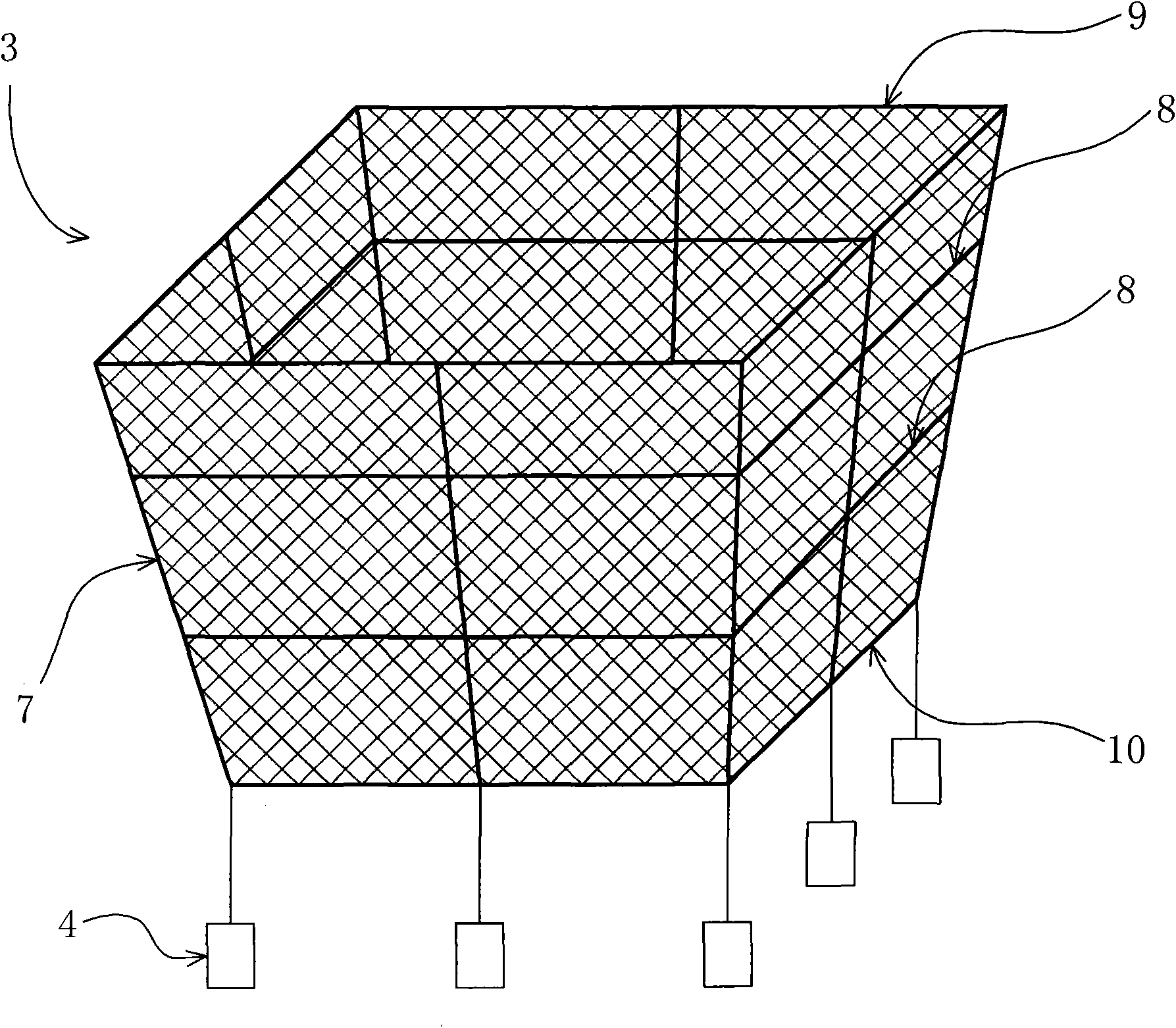

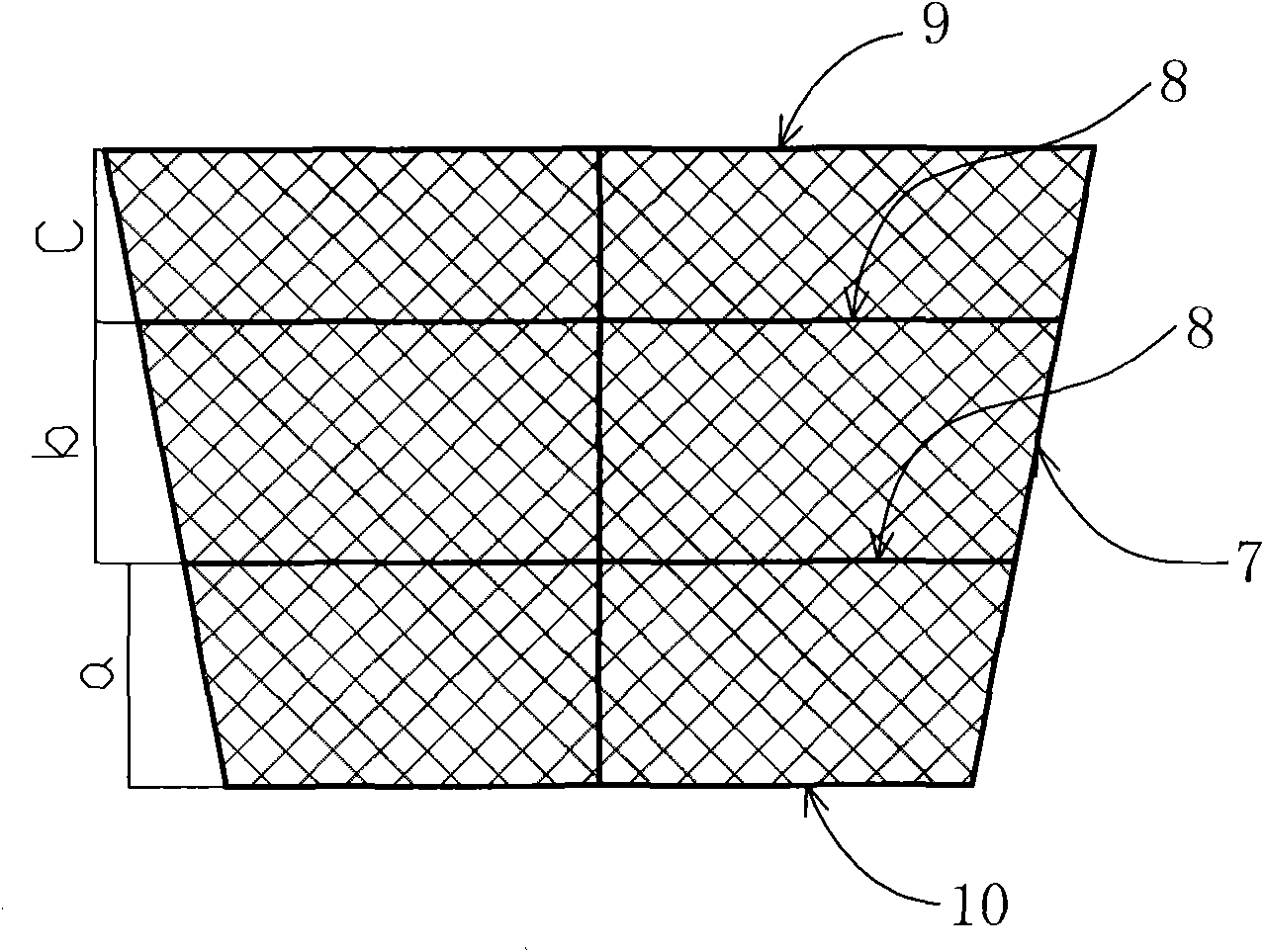

Square platform shape anti-flow net bag used for square-shaped net box

InactiveCN101617641ASimple structureStrong impact resistanceClimate change adaptationPisciculture and aquariaSquare ShapeEngineering

The invention relates to a square platform shape anti-flow net bag used for a square-shaped net box, comprising a net cover, a net bottom, a net body and a sinker. The net cover and the net bottom which are respectively used for forming an upper plane and a lower plane of the square platform respectively consist of a square net piece, a bolsh line fixed at the edge of the net piece and a belly line fixed on the net surface of the net piece; the net body comprises four trapezoidal net pieces for forming four side surfaces of the square platform; the net body is provided with a longitudinal side belly line and a horizontal belly line; in addition, the upper edge and the lower edge of the net body are respectively provided with an upper bolsh line and a lower bolsh line for reinforcing; the bolsh line arranged on the net bottom is connected with the lower bolsh line; and the bolsh line arranged on the net cover is connected with the upper bolsh line, thus forming a closed net bag. The square platform shape anti-flow net bag is specially used for a square-shaped cultivating net box, forms a prestress system of the net box and has strong impact resistance.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

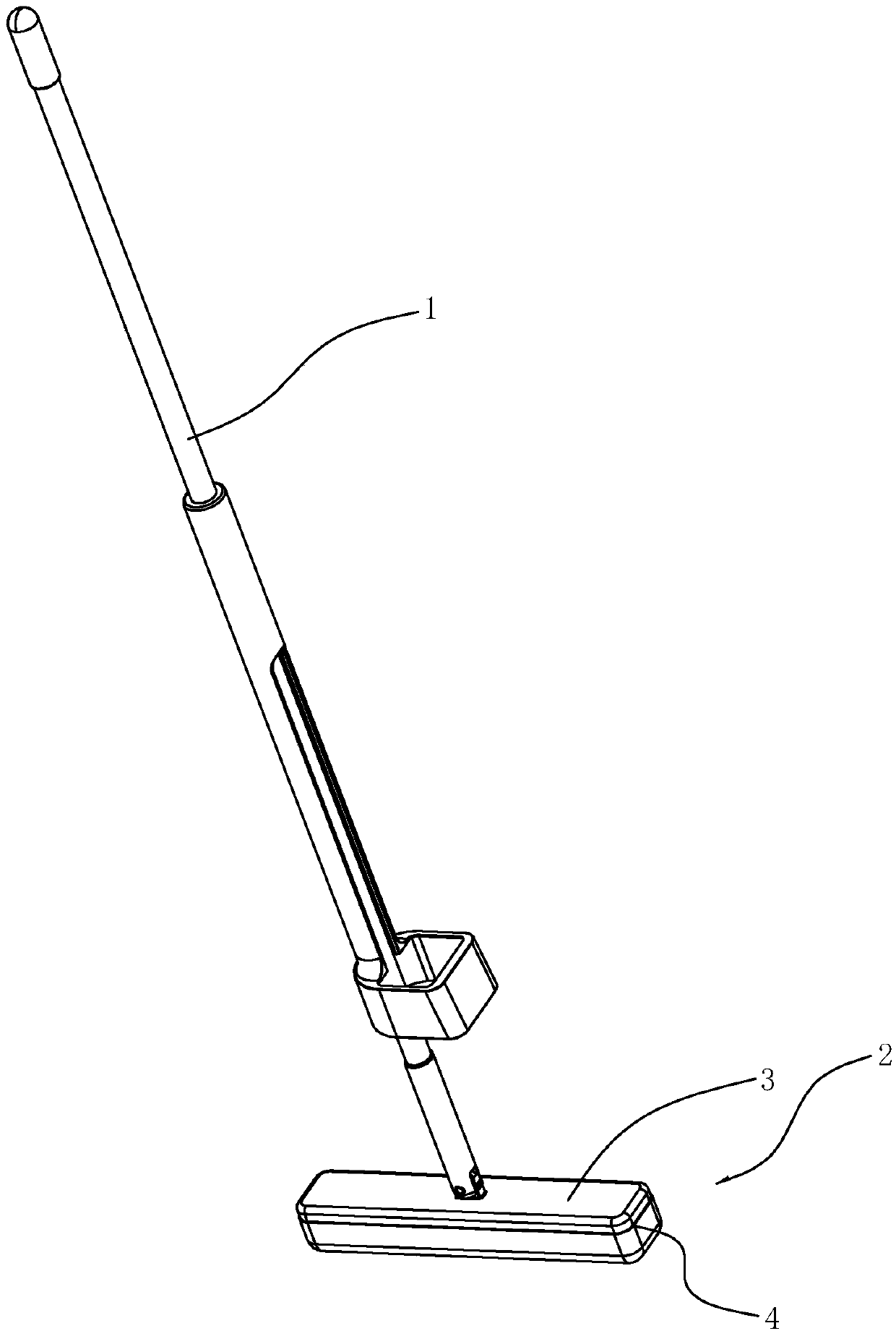

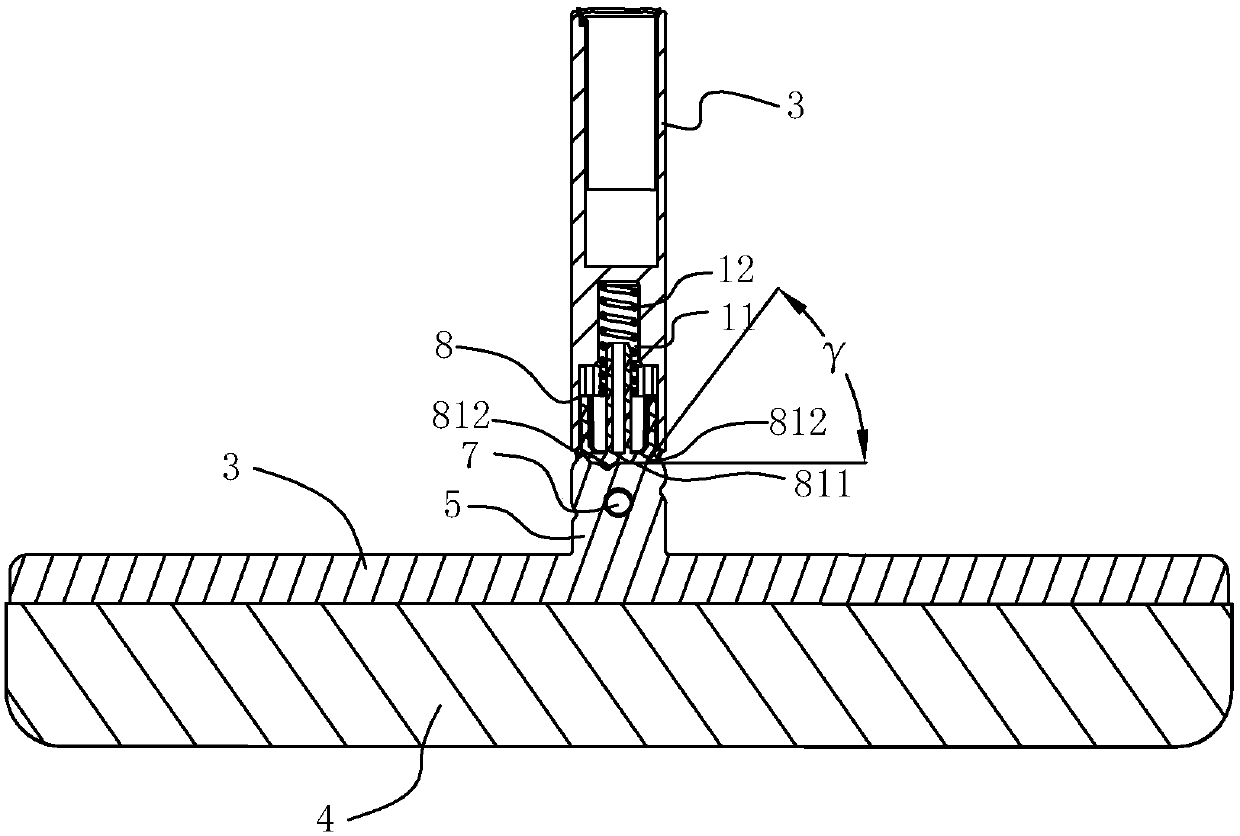

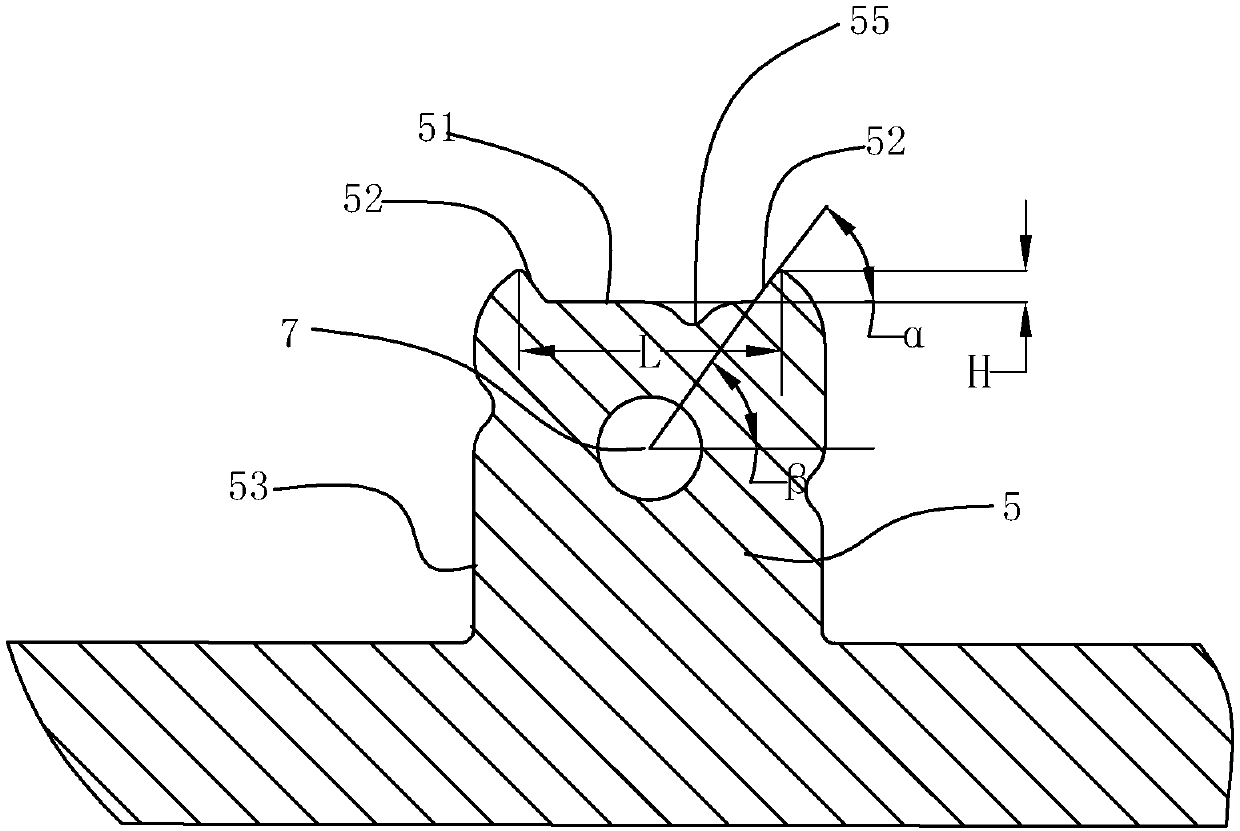

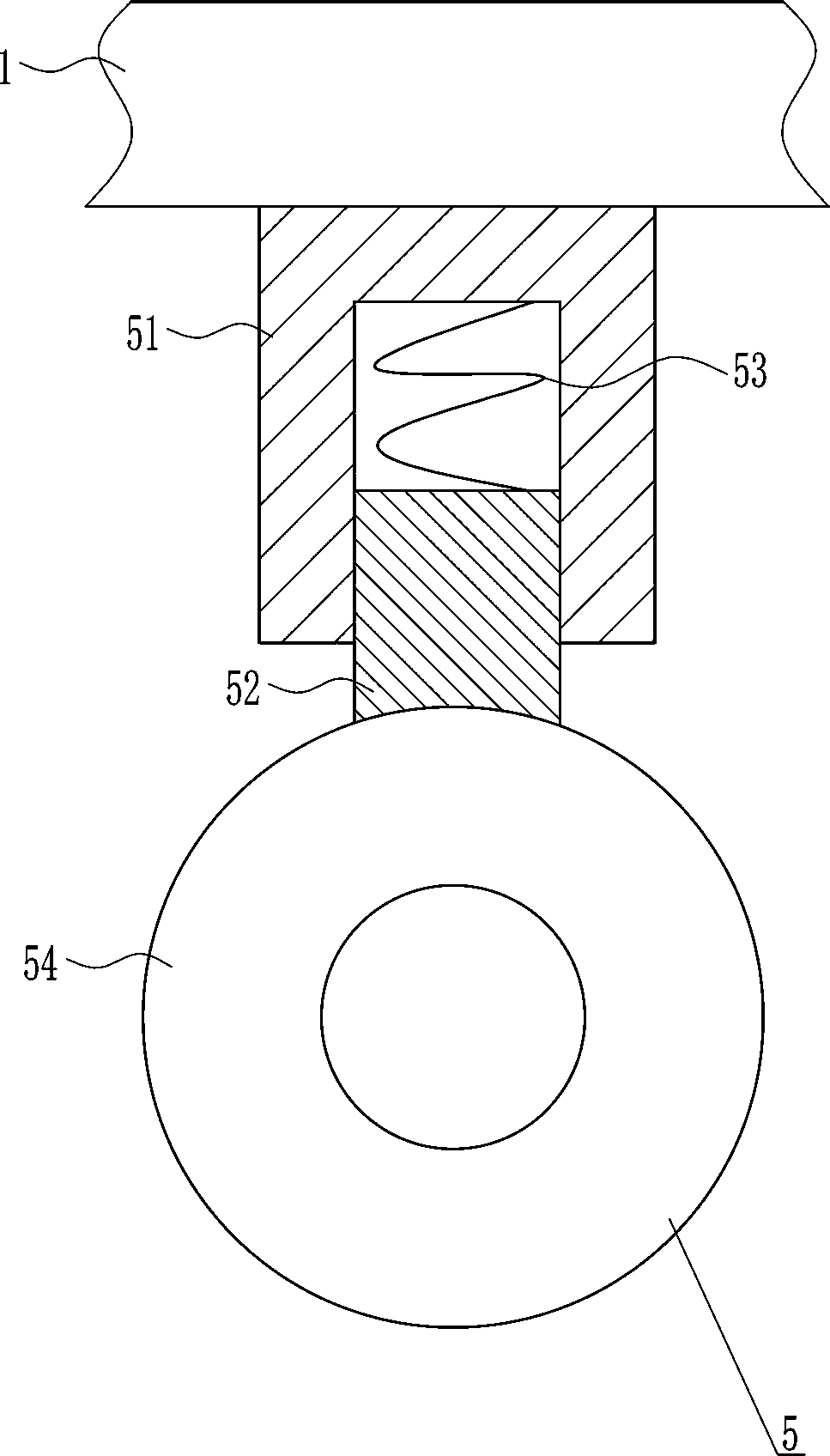

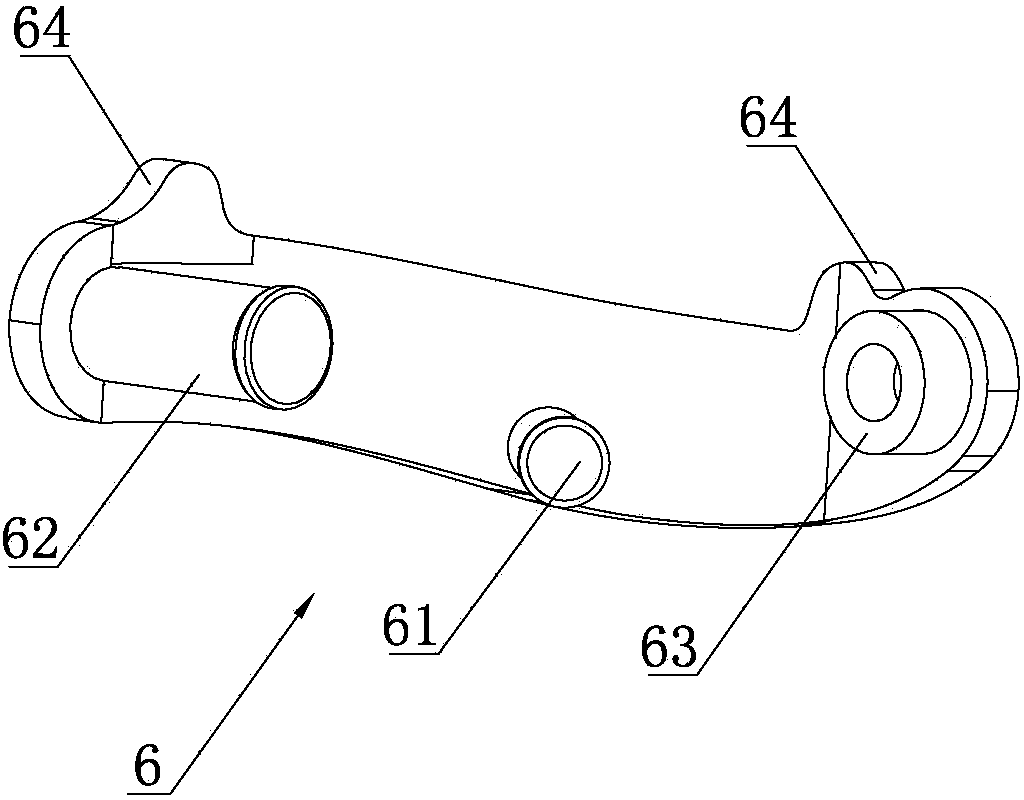

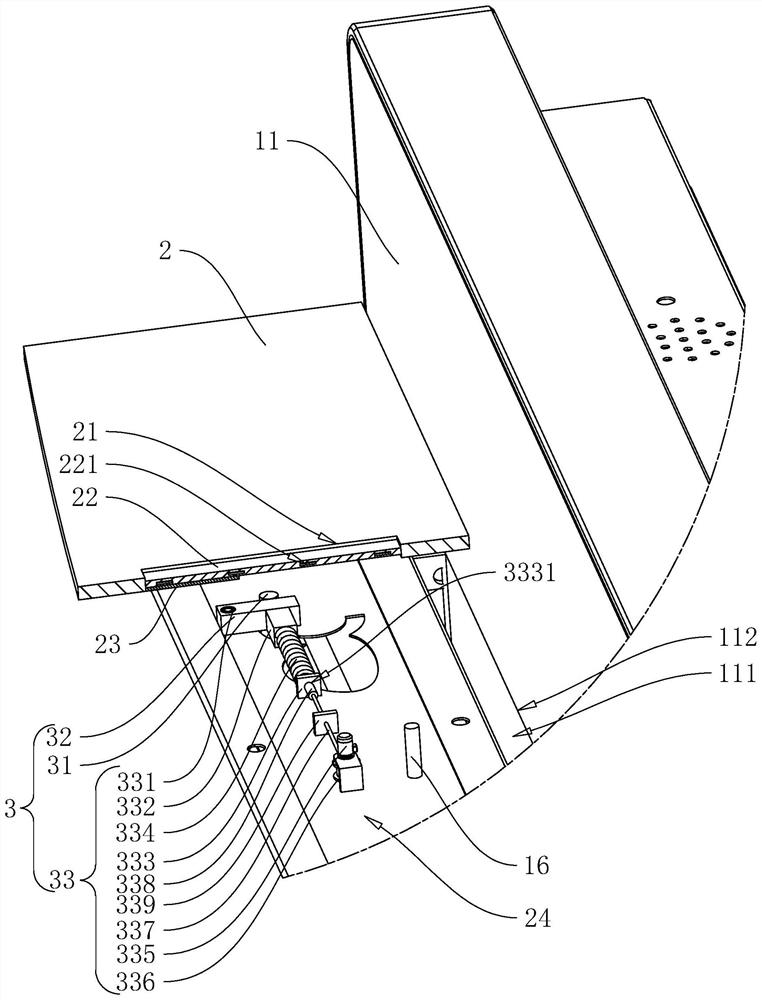

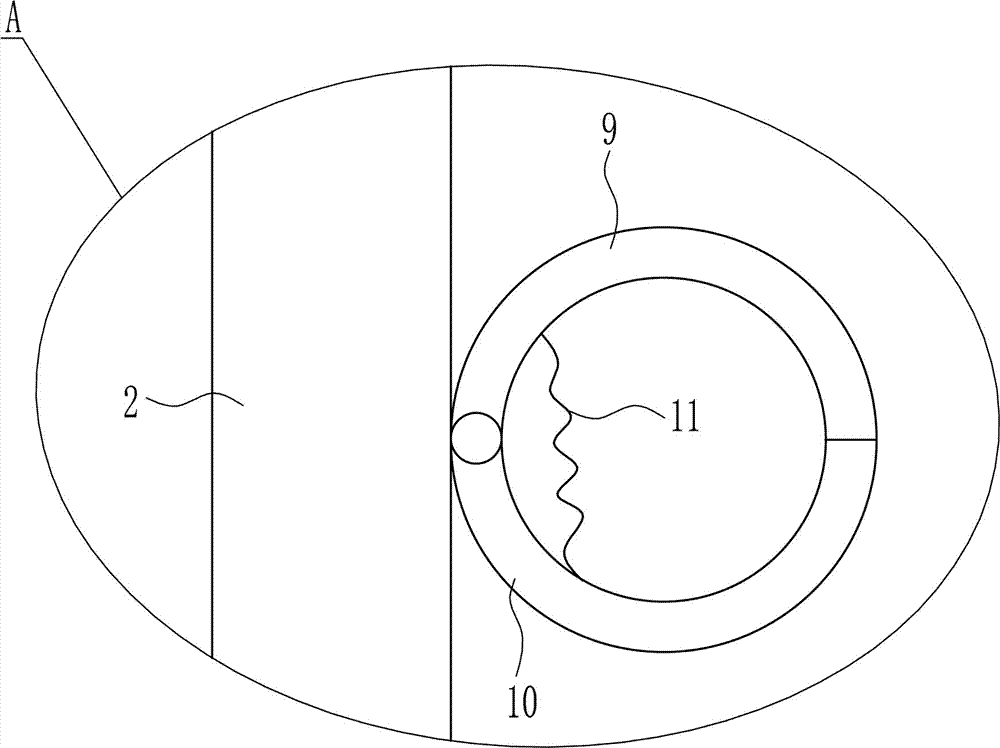

Locating and resetting mechanism of collodion mop

PendingCN109965800AGreat positioningNot easy to foldCarpet cleanersFloor cleanersEngineeringCollodion

The invention provides a locating and resetting mechanism of a collodion mop. The mechanism comprises a first assembly and a second assembly which are hinged through a hinging shaft, wherein the firstassembly comprises a concave hole as well as an elastic part and a clamping block which are arranged in sequence from inside to outside in the concave hole, the second assembly is a lug, the clampingblock always pushes against the lug under the effect of the elastic part and can move along the outer peripheral face of the lug, the outer peripheral face of the lug comprises a middle face in the middle and side faces positioned on the two sides of the middle face, the middle face comprises a connecting face and two limiting faces positioned on the two sides of the connecting face, and the limiting faces extend towards the first assembly and incline towards the side faces. For the locating and resetting mechanism of the collodion mop, a mop head can be located in the vertical state relativeto a mop rod, and meanwhile, the great locating force is available, so that a user is capable of dragging the collodion mop for doing cleaning with great force; and in addition, the mop head of the collodion mop can be folded relative to the mop rod, and thus the storage and washing are convenient.

Owner:宁波蓝小鱼家居科技有限公司

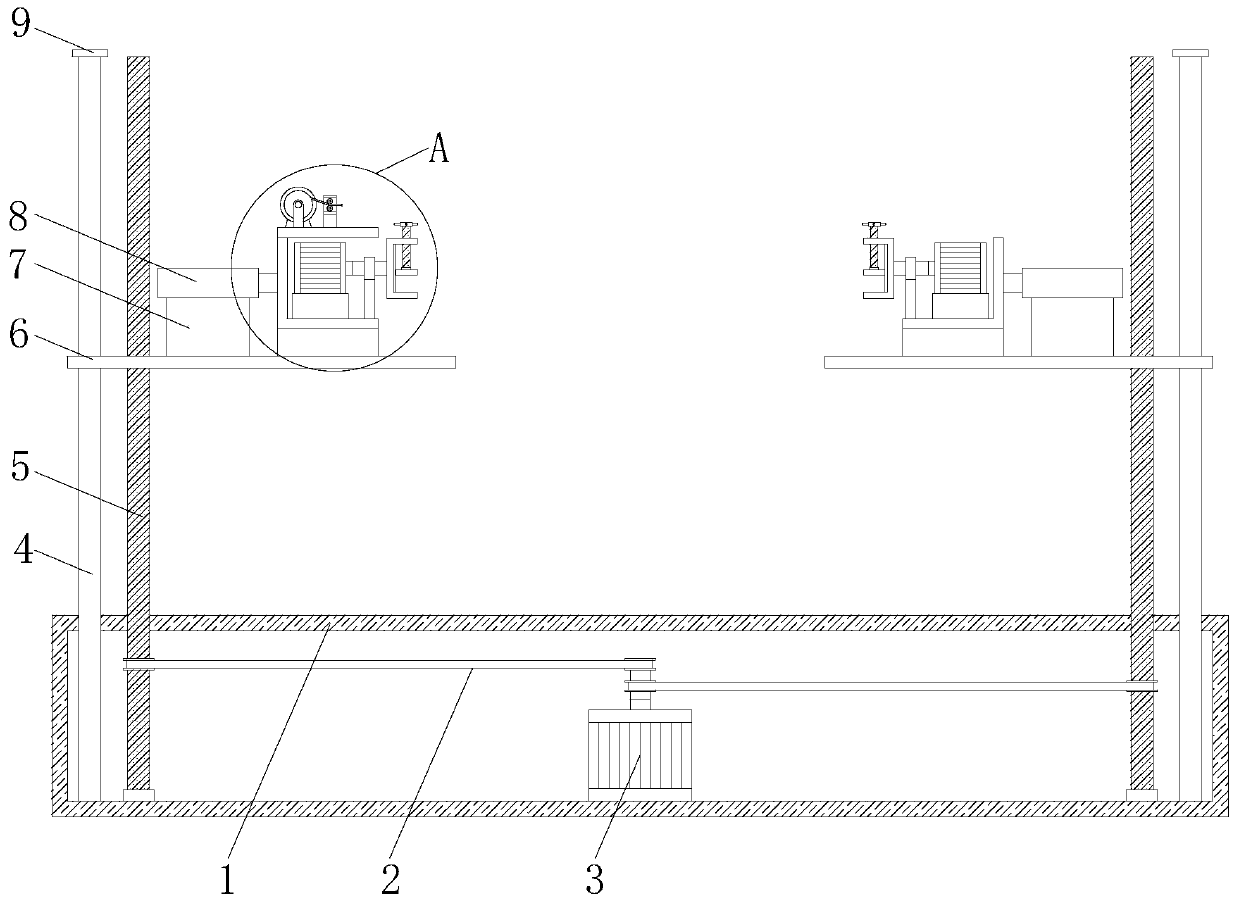

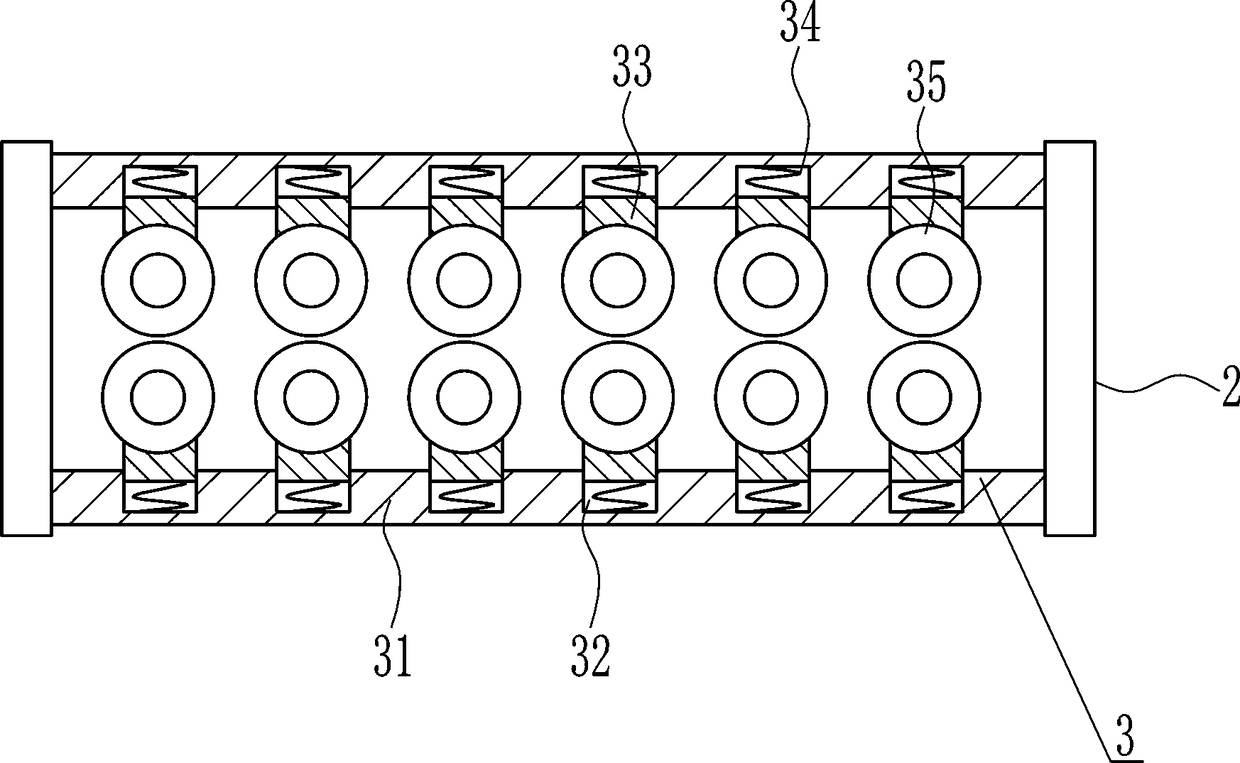

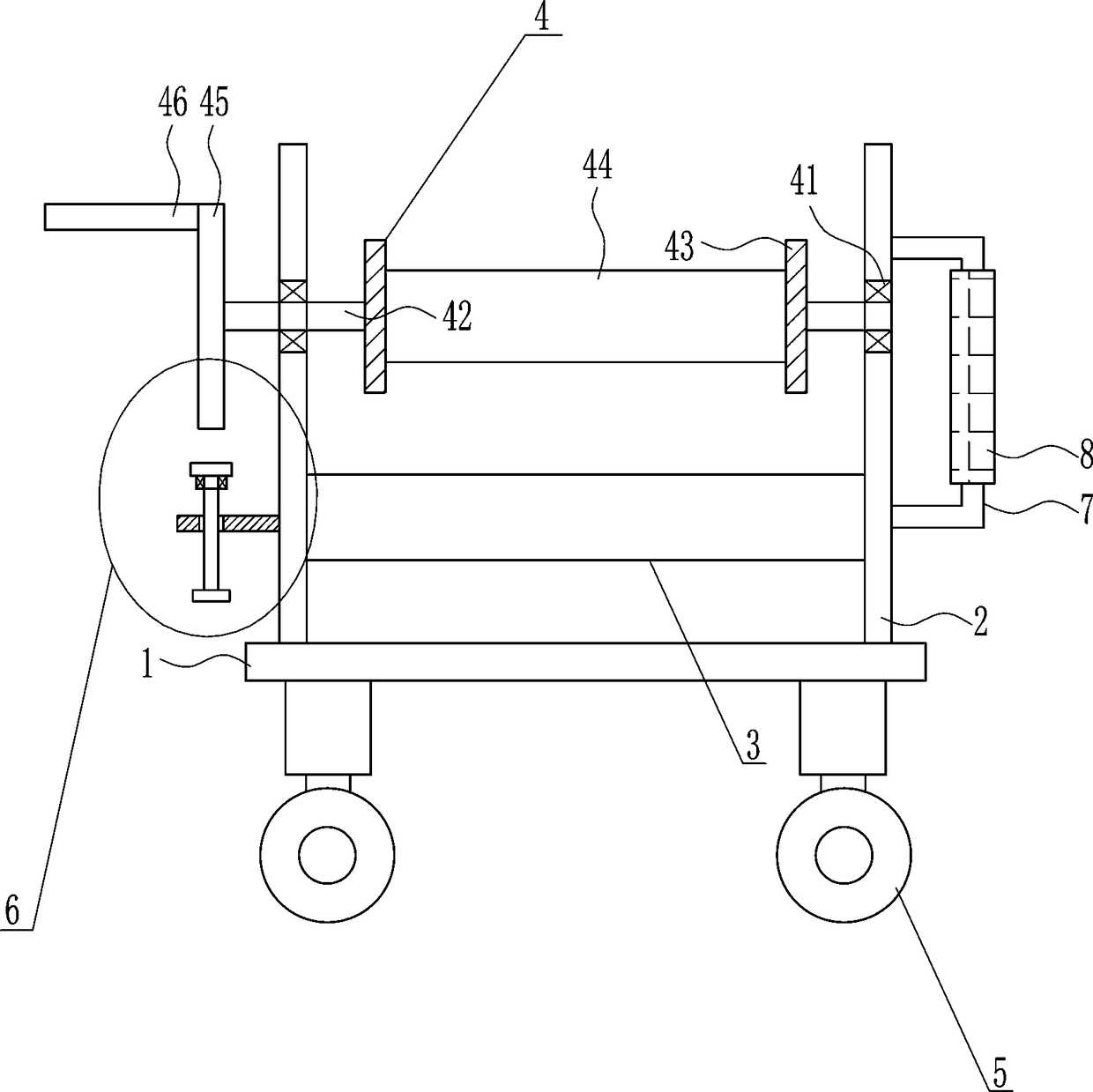

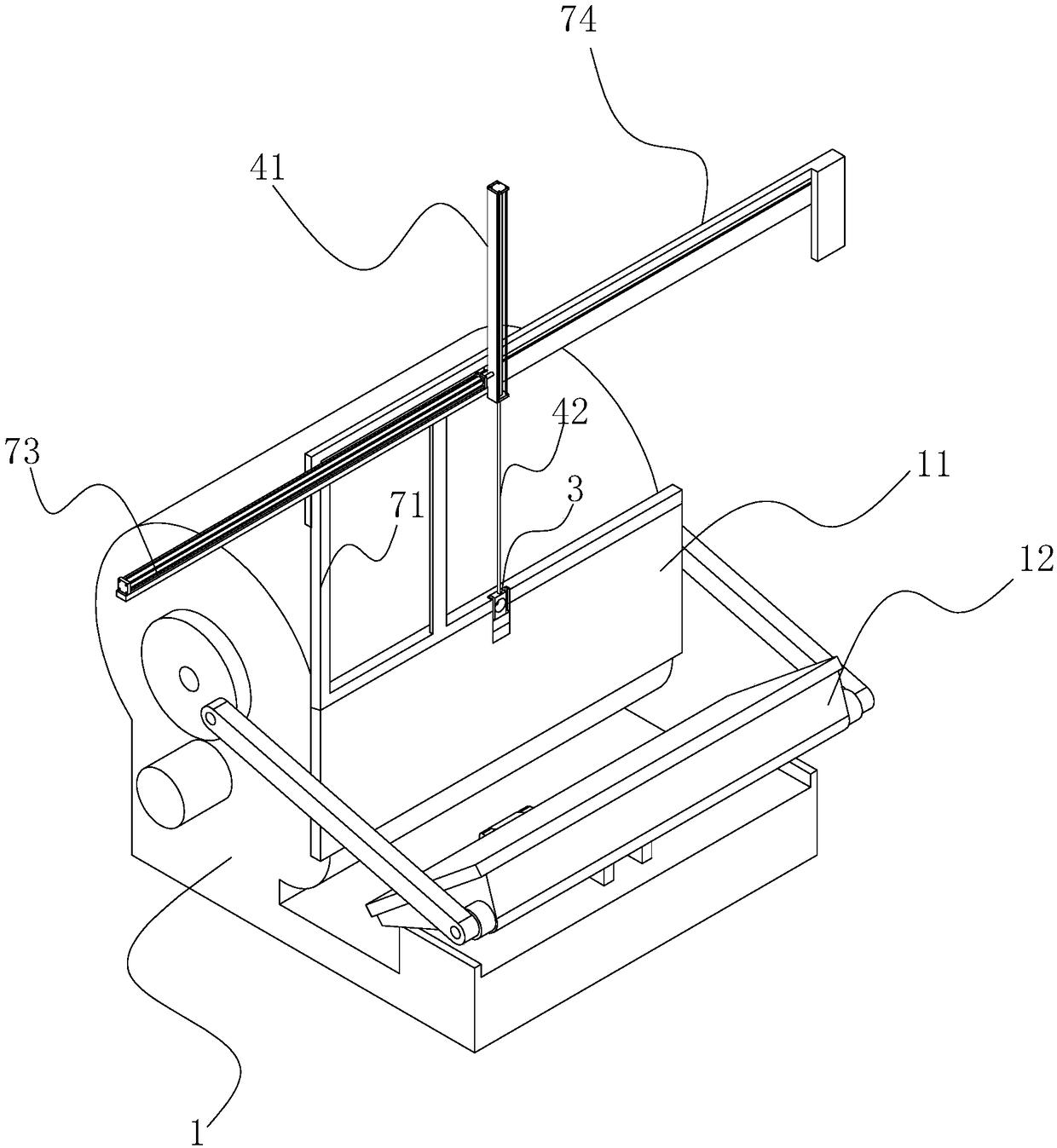

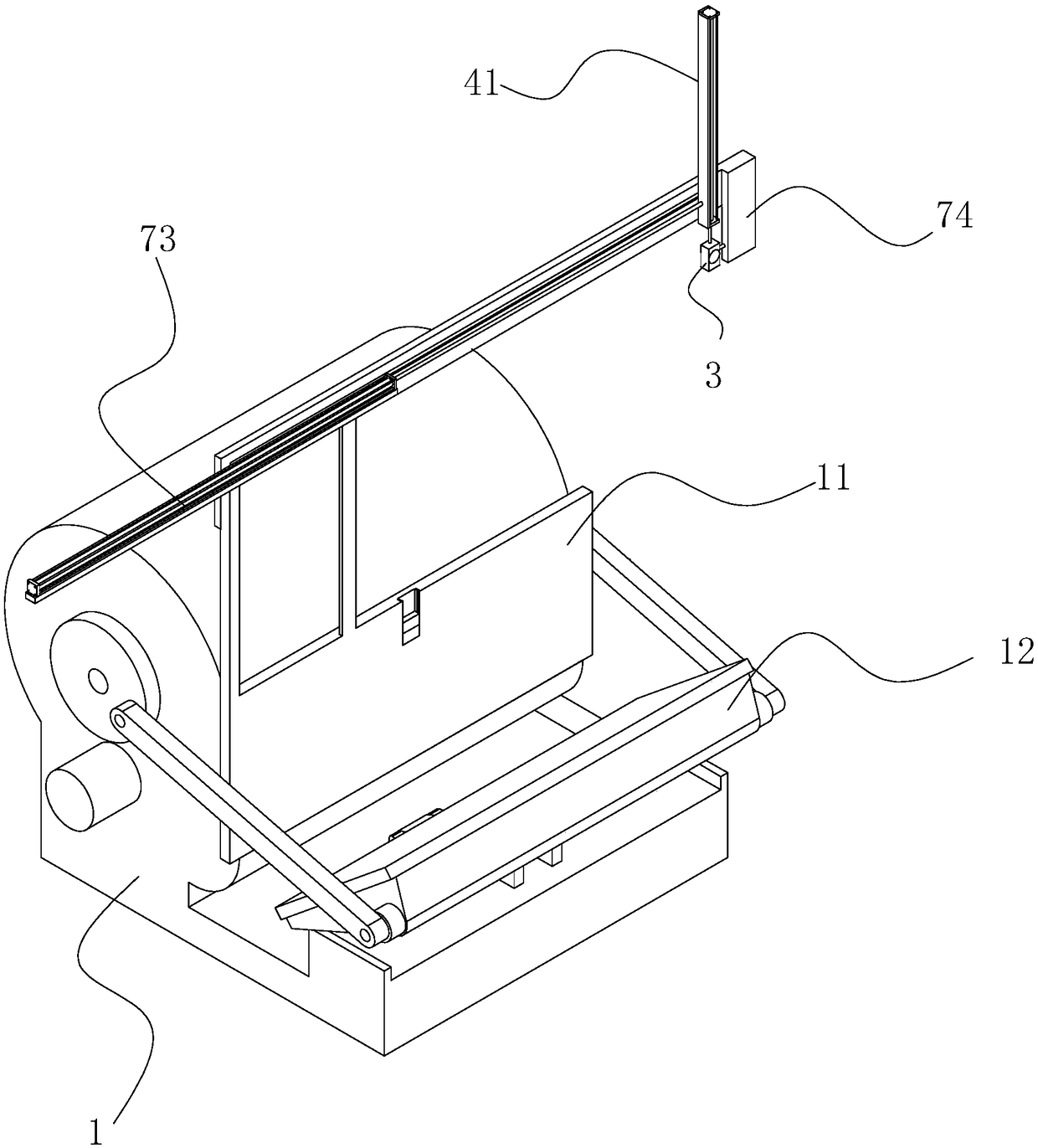

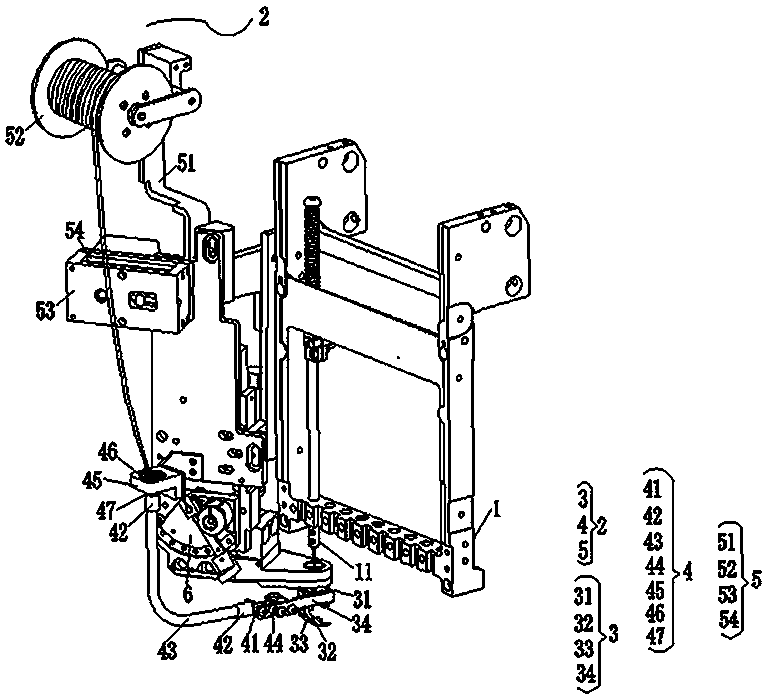

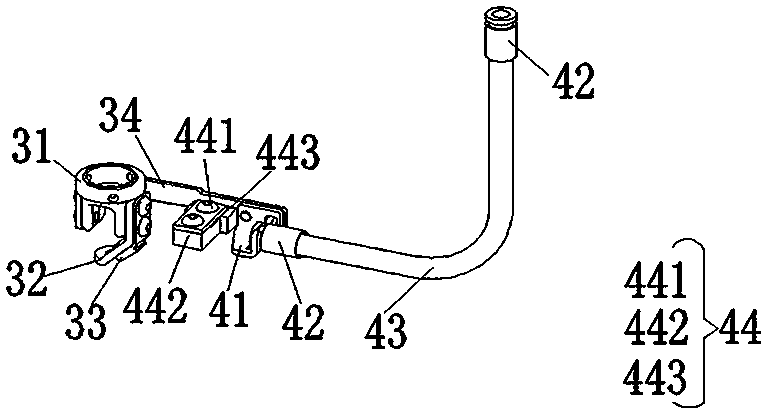

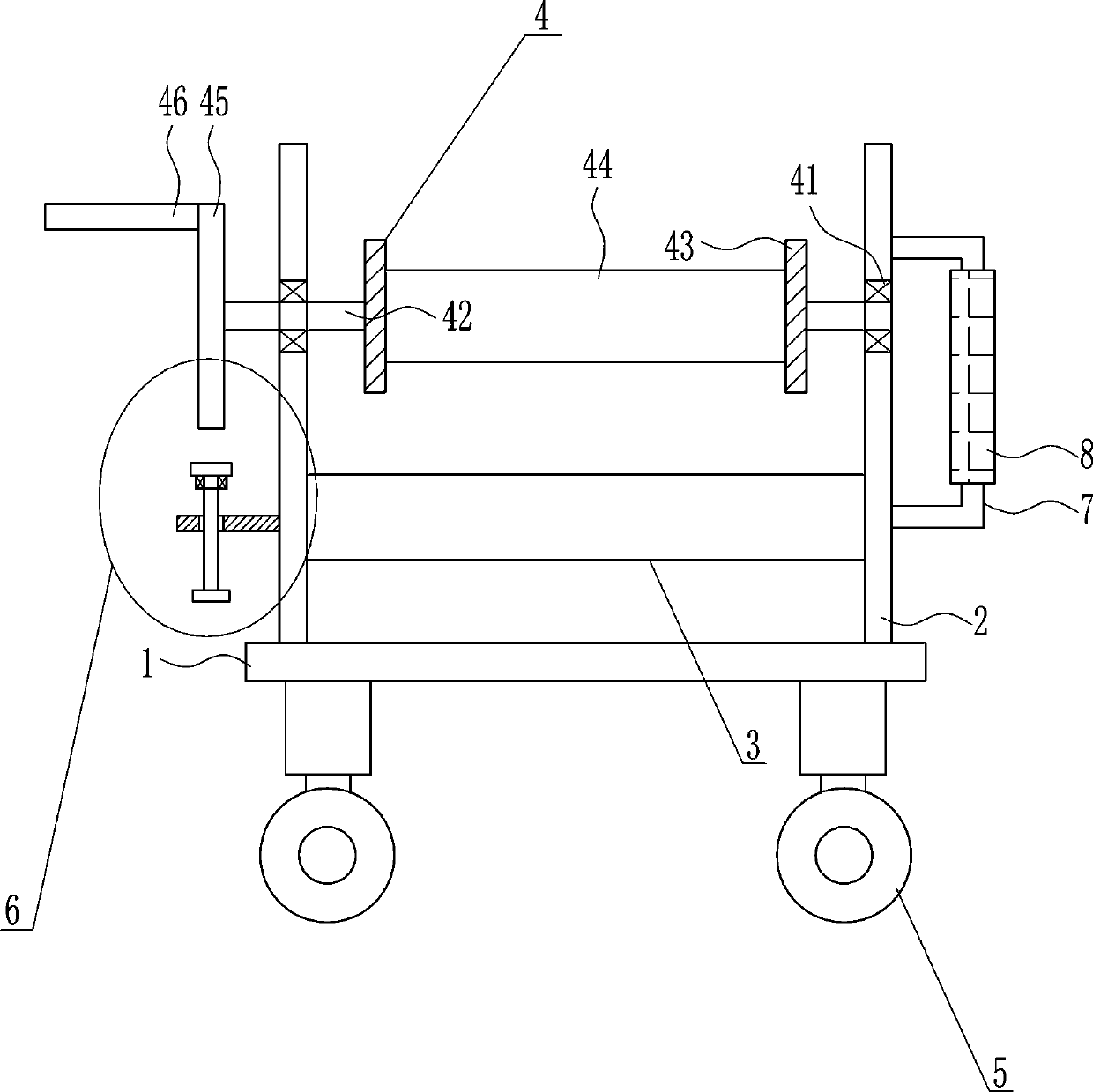

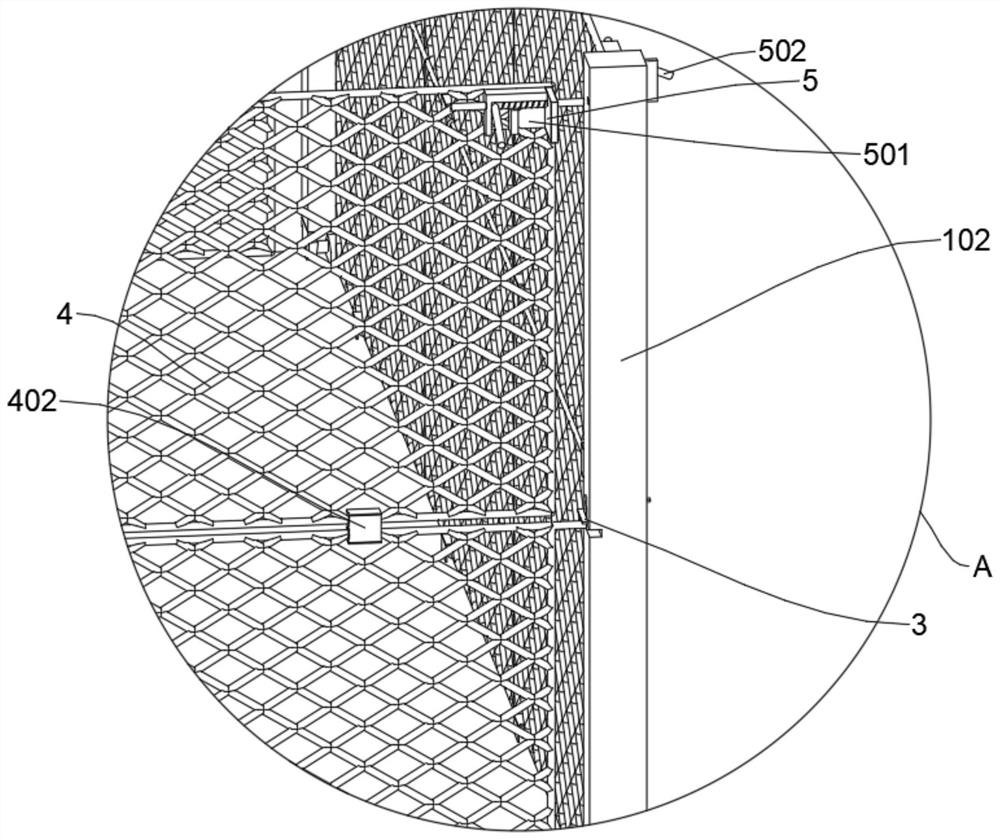

Dense screen rapid winding device for construction site environment protection

ActiveCN108100724ANot easy to foldFast winding speedWebs handlingArchitectural engineeringConductor Coil

The invention belongs to the technical field of construction protection, and particularly relates to a dense screen rapid winding device for construction site environment protection. The dense screenrapid winding device for construction site environment protection is easy to operate, convenient to use and capable of saving time and labor and reducing labor intensity. In order to achieve the technical aims, the dense screen rapid winding device for construction site environment protection comprises a bottom plate and the like; supports are vertically arranged on the top of the bottom plate ina bilateral symmetry manner, a guide device is arranged on the lower portion of the position between the two supports, and a winding device is arranged on the upper portion of the position between thetwo supports. A front pulley and a rear pulley are arranged, the phenomenon that in the winding process, a dense screen is not prone to winding is avoided, winding speed is improved, and the effectsof being simple in structure, convenient to use and capable of saving time and labor and reducing labor intensity are achieved.

Owner:南通永固建设有限公司

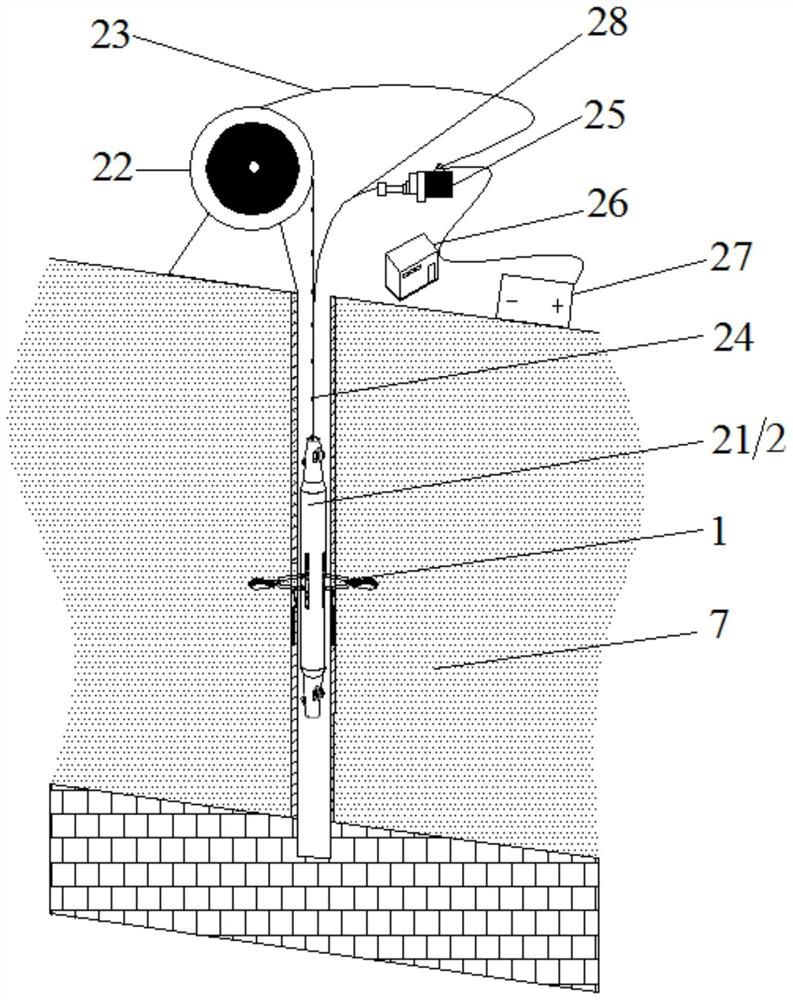

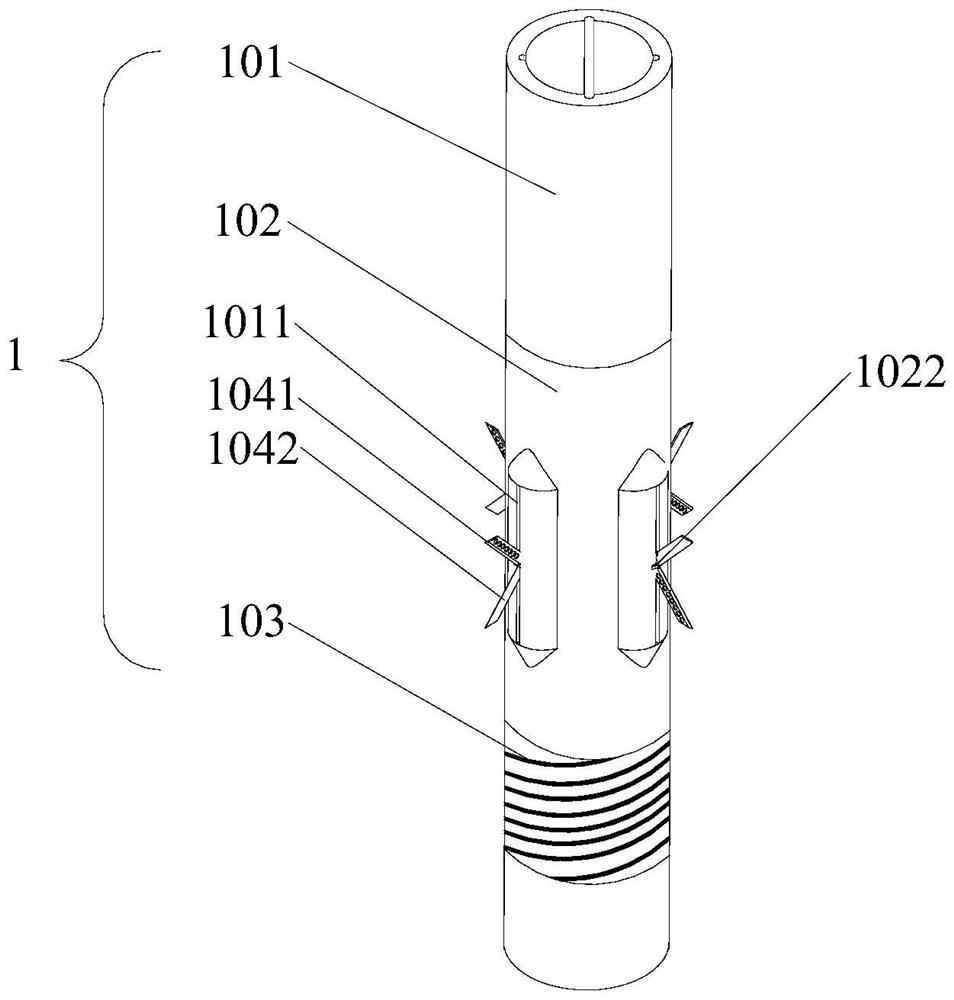

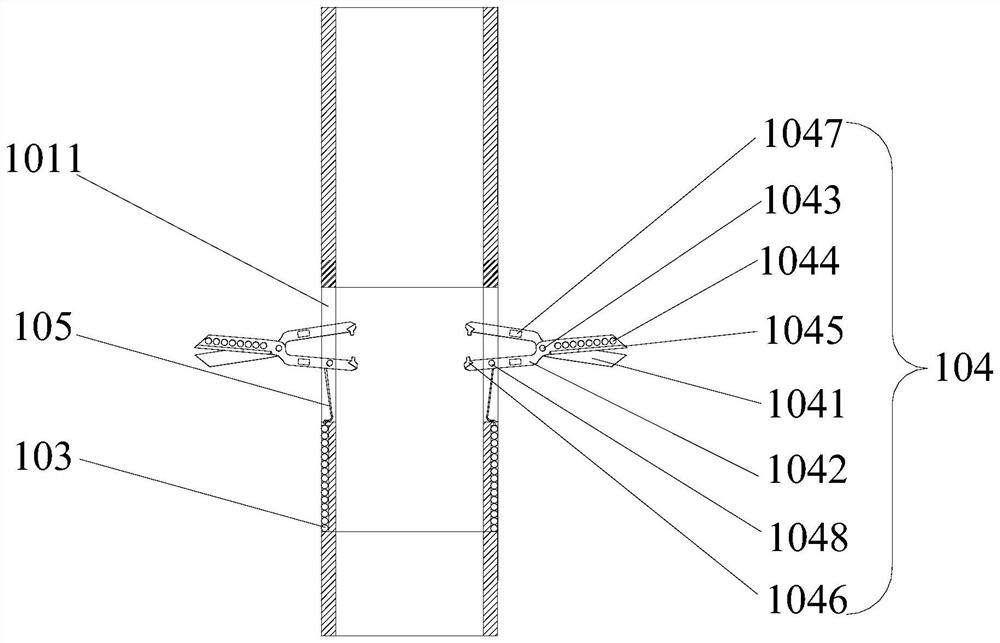

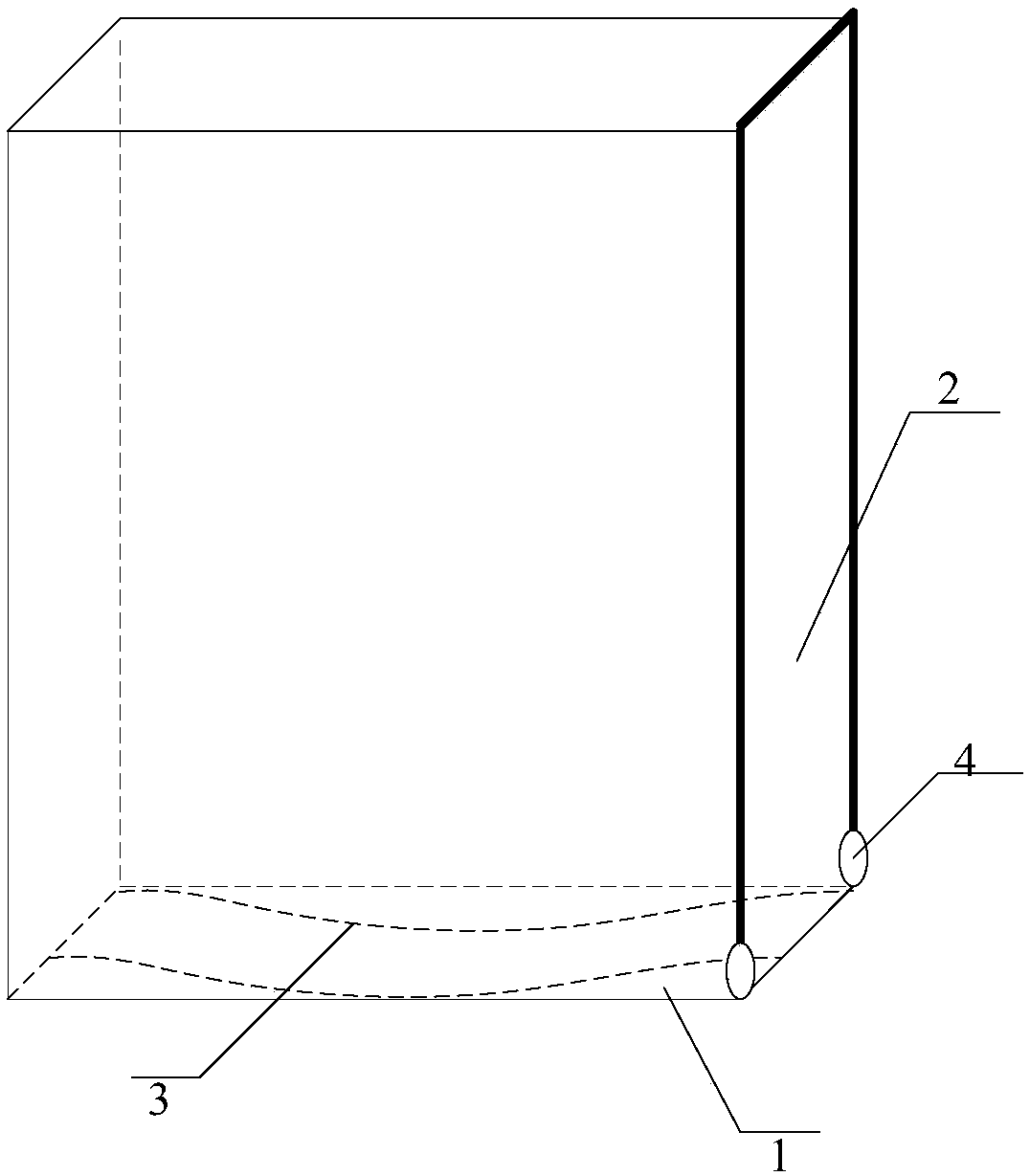

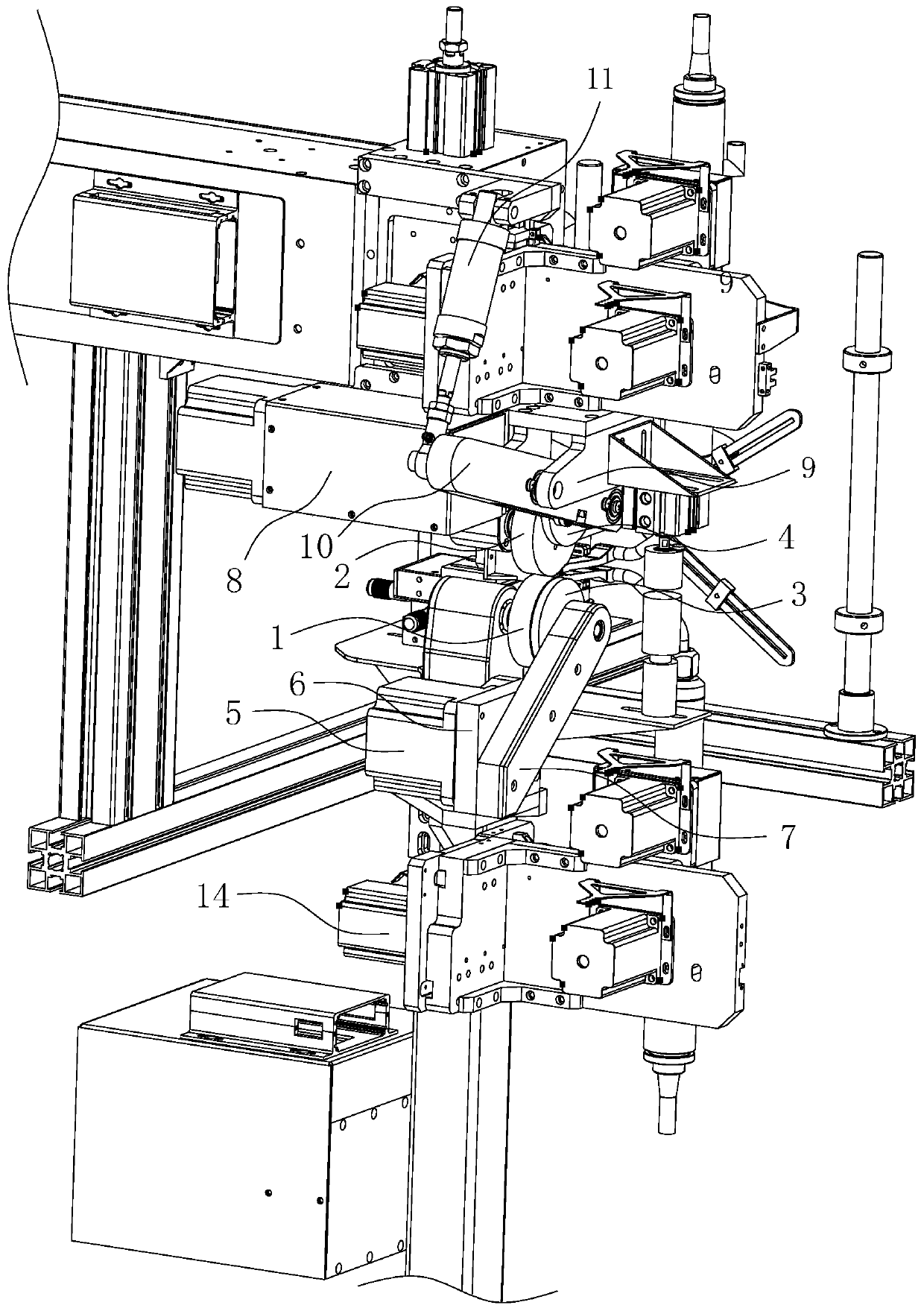

Layout equipment and layout method for multiple integrated sensors in deep part of landslide

ActiveCN113137985AOptimize layoutLower requirementMeasurement apparatus componentsLandslideKnife blades

The invention provides layout equipment and a layout method for multiple integrated sensors in a deep part of a landslide, a penetration type monitoring body comprises a sleeve and a sensor penetration shear, the sensor penetration shear is arranged in a scissor shape, and a first blade and a second blade rotate oppositely or oppositely in the vertical direction, so that the sensor penetration shear has an initial position and a monitoring position; when the sensor penetration shear is located at the initial position, the ends of the pressed parts of the first blade and the second blade are arranged at intervals in the vertical direction, when the sensor penetration shear is located at the monitoring position, the pressed parts move oppositely, and the shearing part penetrates out of the mounting hole to shear the sliding body. And a monitoring body arrangement system drives the sensor penetration shears to move from the initial position to the monitoring position. The technical scheme provided by the invention has the beneficial effects that the scissor-shaped sensor penetration shear is mounted on the sleeve, and the shearing part is sheared into a soil body, so that the stress is balanced, and the requirement on the sleeve is low; and the arrangement device adopts a local static force application design, is balanced in static force, is not easy to turn over, has low requirements on a pull rope, and does not generate winding.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

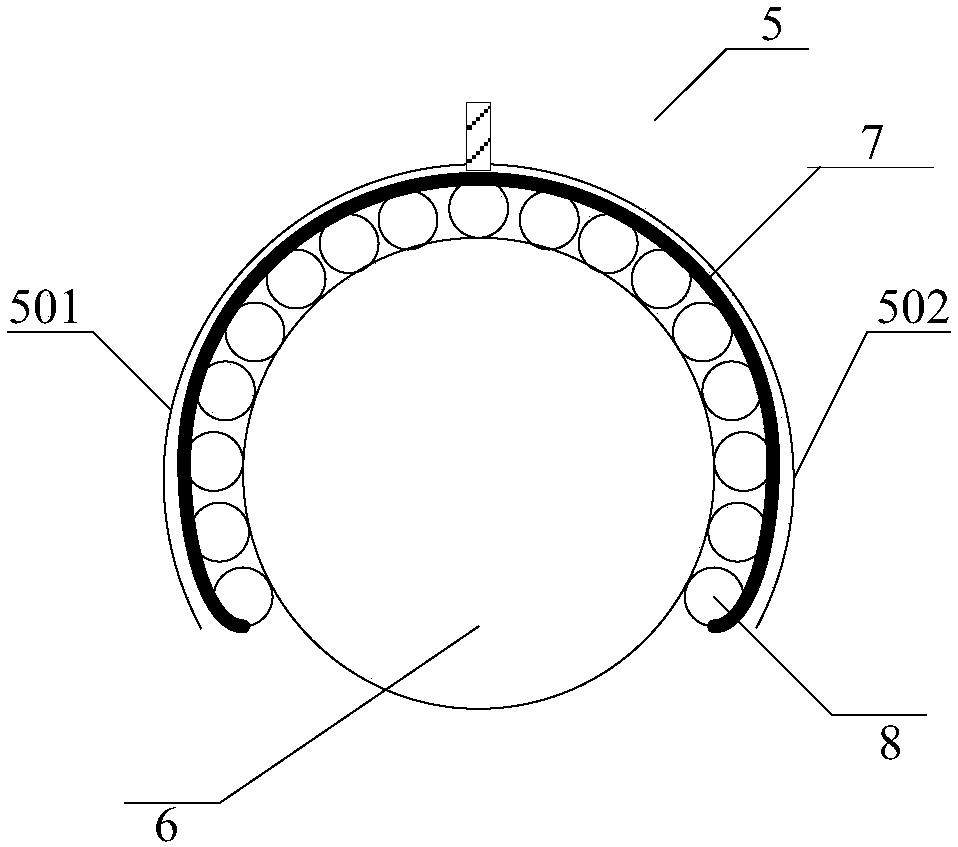

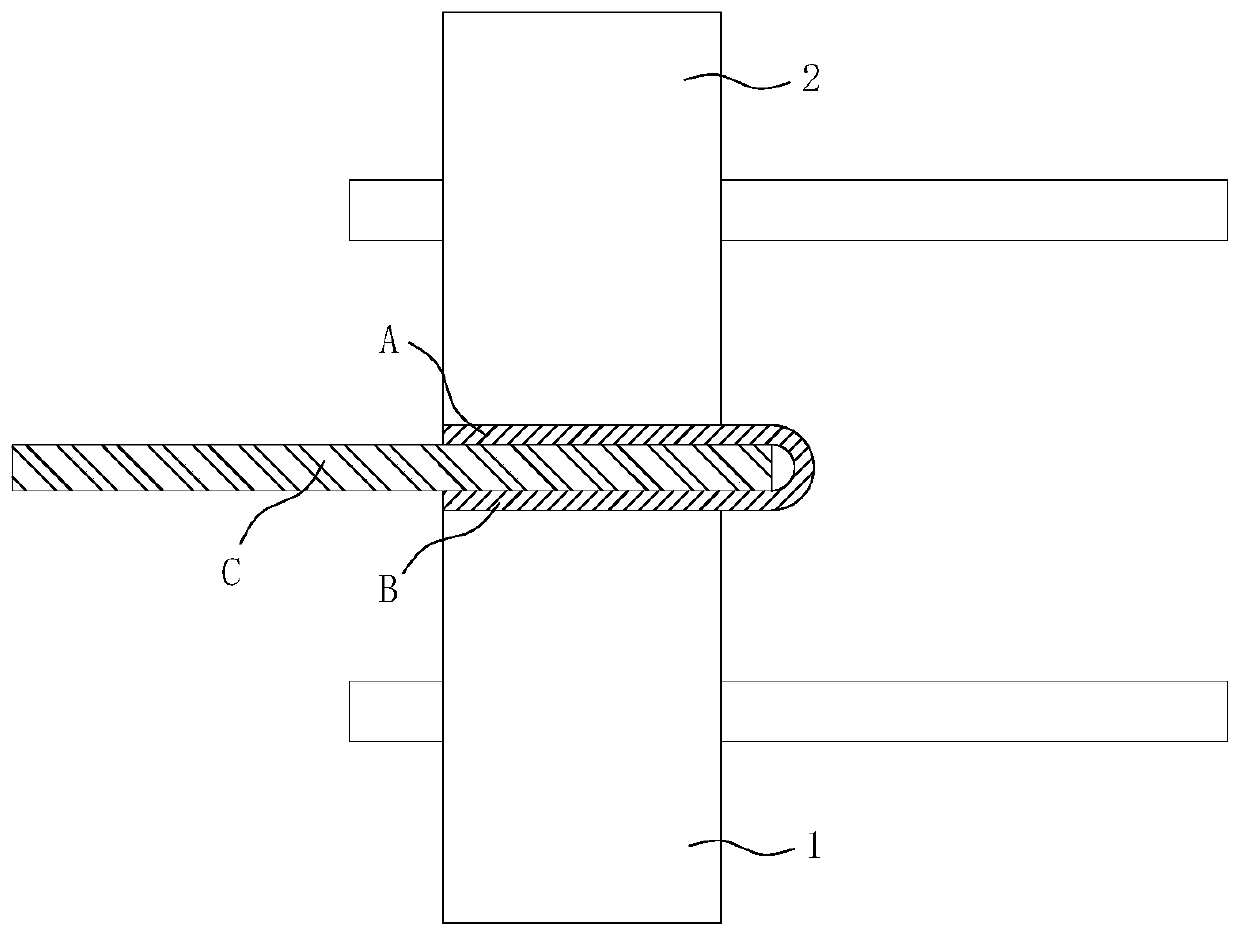

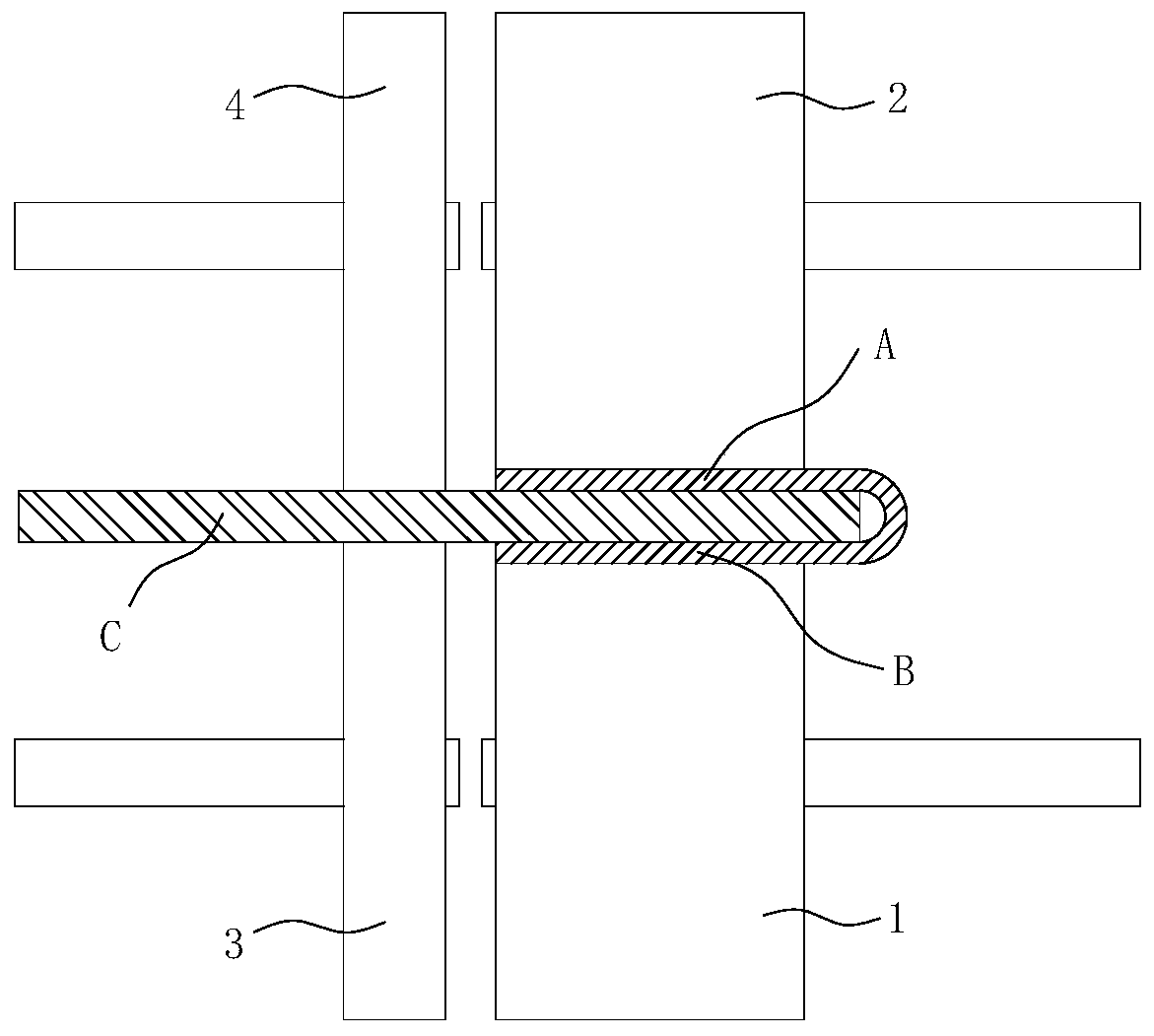

Rotary pressing tooling for manufacturing asymmetric T-shaped rotary pressing belt wheels

InactiveCN102672039ANot easy to foldNot prone to delaminationShaping toolsEngineeringForming processes

The invention relates to a rotary pressing tooling for manufacturing asymmetric T-shaped rotary pressing belt wheels. An upper core mold and a lower core mold are arranged on rotary pressing equipment, a T-shaped thickening rotary wheel, a flat rotary wheel, a preforming tooth rotary wheel and a final forming tooth rotary wheel are respectively arranged on respective rotary wheel shafts, each rotary wheel and the upper and lower core molds are in corresponding arrangement, the work surface of the T-shaped thickening rotary wheel is provided with a groove, and the groove corresponds to a plate material tightly clamped by the upper core mold and the lower core mold. Materials are regulated to uniformly flow towards two sides according to proportions through the contact area between the circular arc of the groove and the material, the material flowing speed is also limited by the groove, the extrusion on the materials is also enhanced in the stack rotation process, the compactness is realized, the cracking and delamination possibilities are reduced, and the forming stability is improved. The flat rotary wheel is mainly used for continuously pushing distributed materials until the inner walls at two T-shaped sides are fully pasted with the upper core mold and the lower core mold through feeding. The rotary pressing tooling has the advantages that the processing process is stable, the rotary pressing effect is good, and conditions of folding, delamination and fracture of the materials cannot occur in the forming process.

Owner:东风襄阳旋压技术有限公司

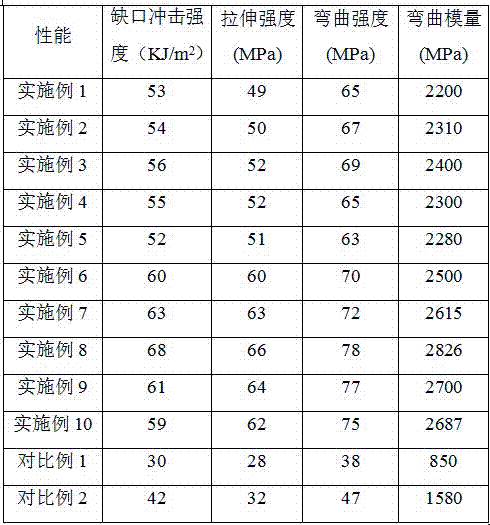

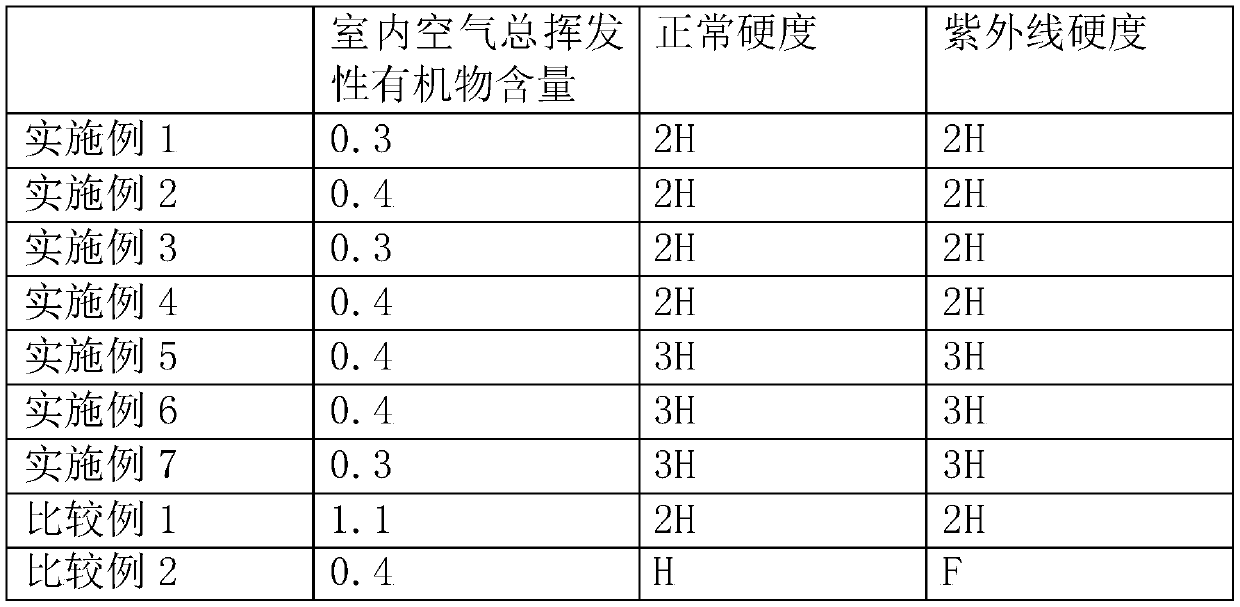

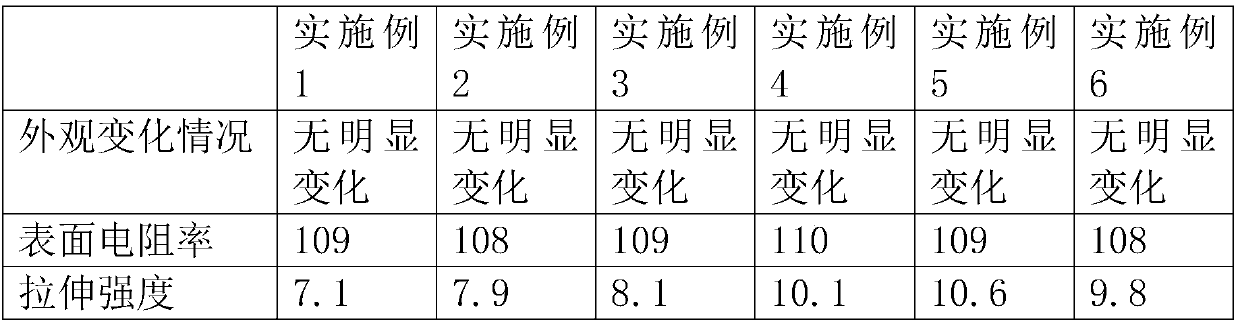

Spraying-free polycarbonate/acrylonitrile styrene/ultrahigh molecular weight polyethylene (PC/AS/UHMWPE) composite material and preparation method thereof

The invention relates to the technical field of macromolecules, in particular to a spraying-free polycarbonate / acrylonitrile styrene / ultrahigh molecular weight polyethylene (PC / AS / UHMWPE) composite material and a preparation method thereof. The composite material is prepared from the following raw materials in parts by weight: 20-80 parts of polycarbonate, 20-50 parts of acrylonitrile-styrene resin, 20-70 parts of UHMWPE, 5-15 parts of a brightening agent, 3-10 parts of glass beads, 2-8 parts of an antioxidant, 1-5 parts of anti-ultraviolet (UV) agent and 2-10 parts of a heat stabilizer. The PC / AS / UHMWPE composite material provided by the invention has better properties such as flow property, bright property, self-lubricity, wear resistance and weather resistance, and is good in forming property and processing properties, low in cost and high in use value; the preparation method provided by the invention is simple, convenient to operate and control, stable in quality, high in production efficiency and low in production cost, thus being suitable for large-scale industrial production.

Owner:广东壹豪新材料科技股份有限公司

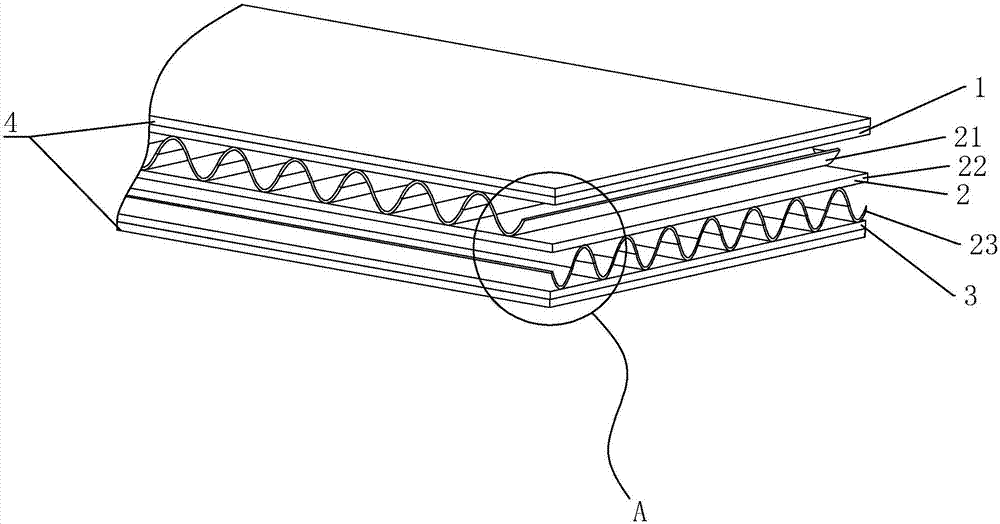

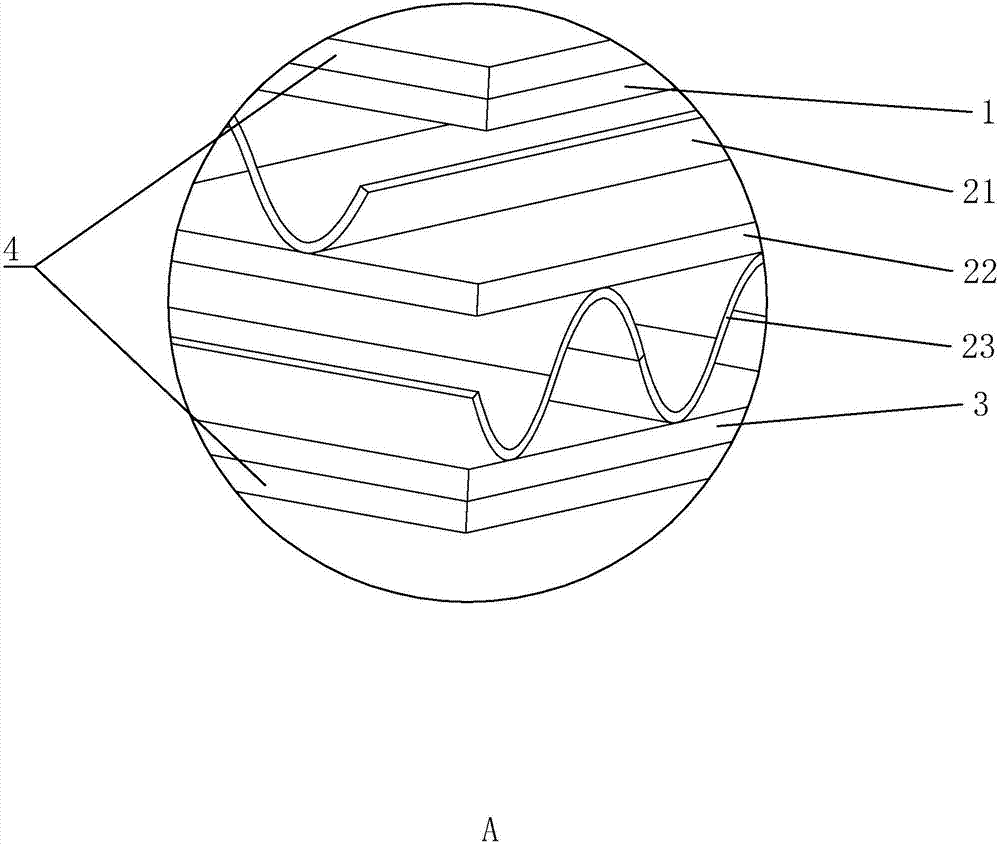

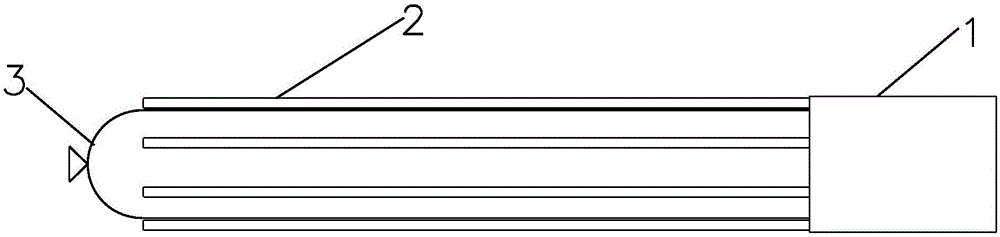

Anti-crushing corrugated board

InactiveCN106976293ASimple structureImprove bearing strengthFlexible coversWrappersEngineeringUltimate tensile strength

The invention discloses a compression-resistant corrugated cardboard. The main points of the technical scheme are as follows: from the outside to the inside, there are face paper, paper core layer and inner paper; The lower paper core layer, the upper paper core layer and the lower paper core layer are all arranged in a parabolic shape, and the extension direction of the upper paper core layer and the lower paper core layer are arranged at an angle. By adopting the above technical scheme, the structure of the traditional paper core layer has been improved. The orientations of the upper paper core layer and the lower paper core layer are different. When extruding force, since the extension direction of the upper paper core layer and the lower paper core layer are set at an angle (that is, they are not parallel to each other), the position of the linear pressure on the other layer must not be along the parabolic groove. The pressure bearing strength is relatively high, and it is not easy to fold over.

Owner:海宁恒辉包装有限公司

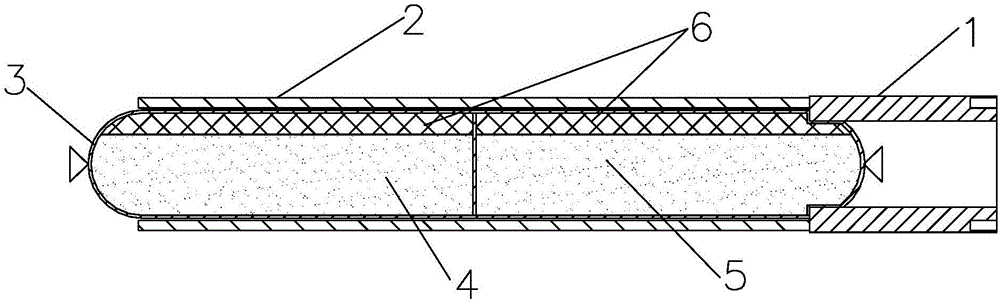

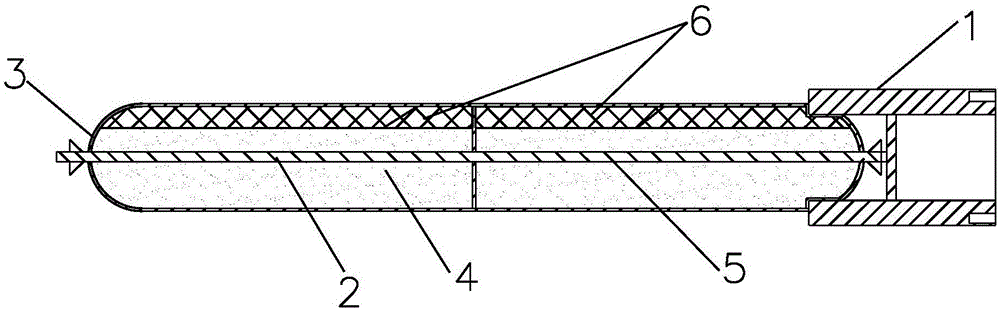

Packaging structure for long resin anchoring agent

The invention relates to a packaging structure for a long resin anchoring agent. The packaging structure for the long resin anchoring agent comprises a sleeve, an anchoring agent packaging bag and a plurality of reinforcing ribs arranged in the circumference and / or the middle of the sleeve, wherein the reinforcing ribs are arranged in the length direction of the sleeve, the anchoring agent packaging bag is arranged on the sleeve, and the reinforcing ribs are used for supporting the anchoring agent packaging bag. The packaging structure has the beneficial effects that an anchor rod or an anchor rope is only required to be matched with one roll of the long resin anchoring agent, time for continuously arranging multiple rolls of the resin anchoring agents is saved, the resin anchoring agent is flexible and not prone to breakage under the action of the reinforcing ribs, and installation is convenient. The resin anchoring agent has more remarkable effect on construction especially under conditions of large section, full-length anchoring, surrounding rock breaking or bed separation. The packaging structure for the long resin anchoring agent is simple in structure, not prone to breakage, low in worker labor intensity and good in anchoring effect and has wide practicability.

Owner:HUATING COAL GRP

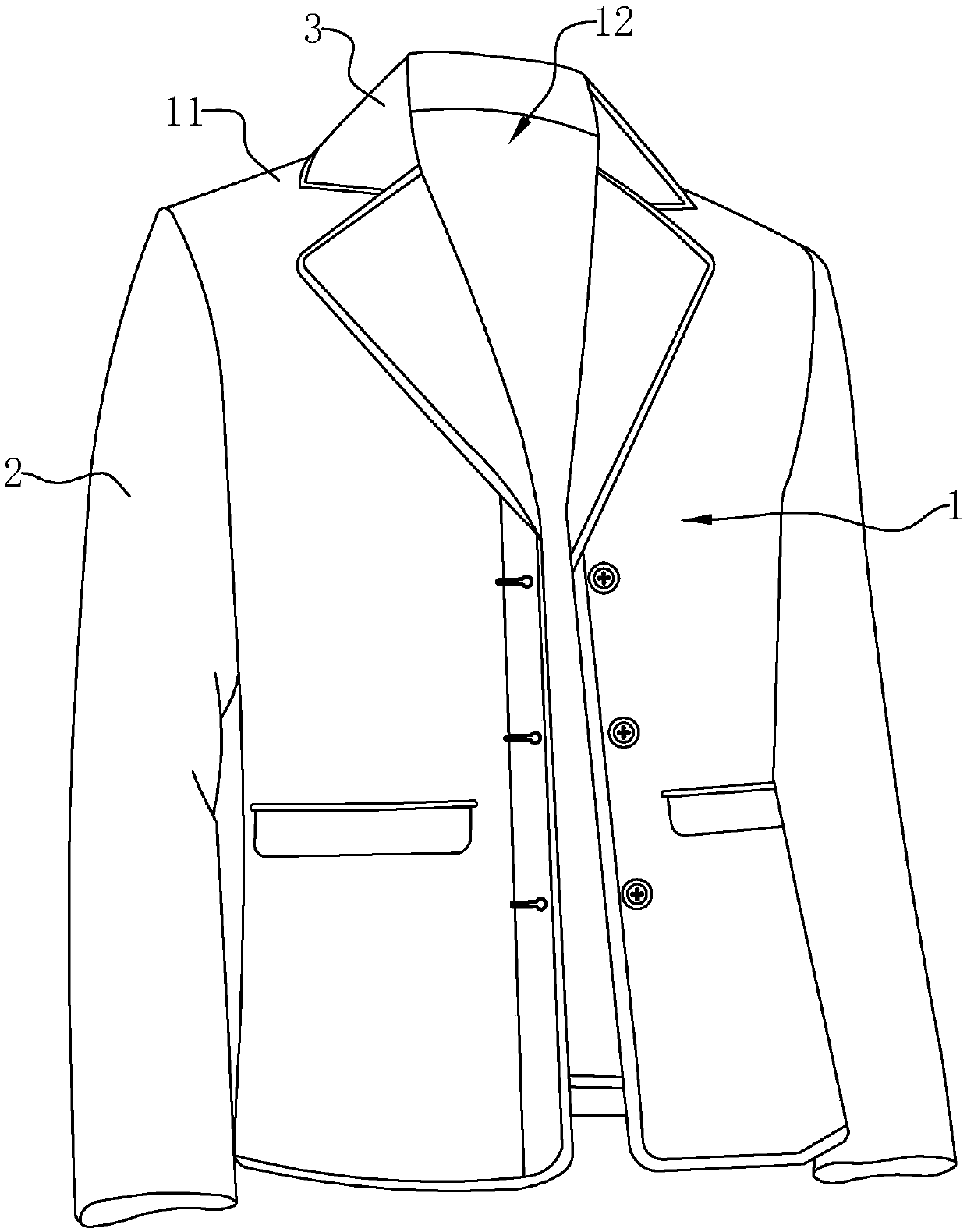

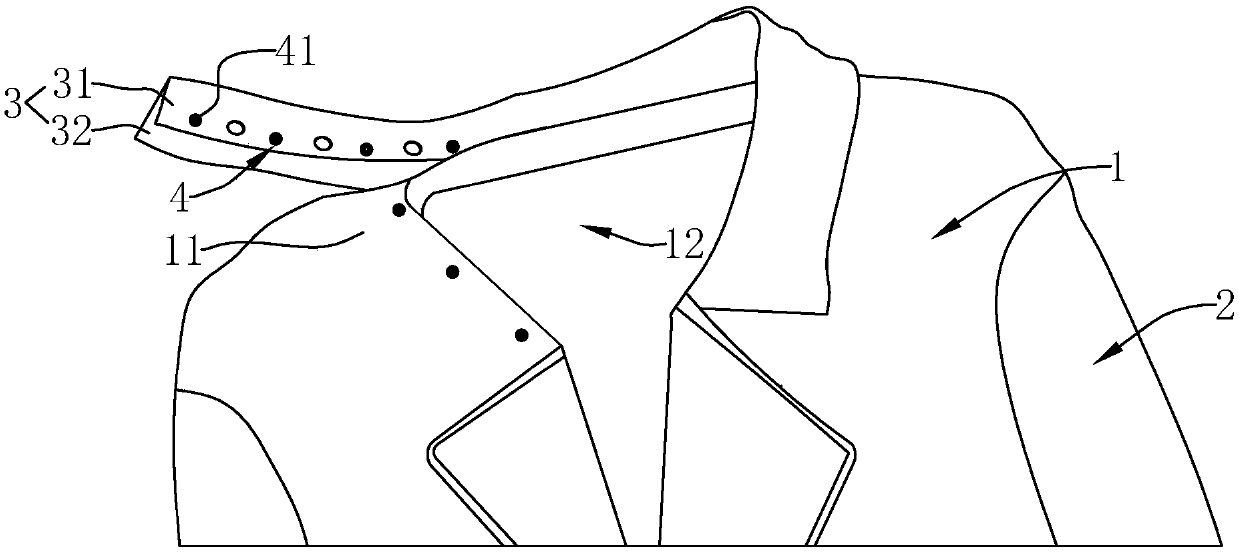

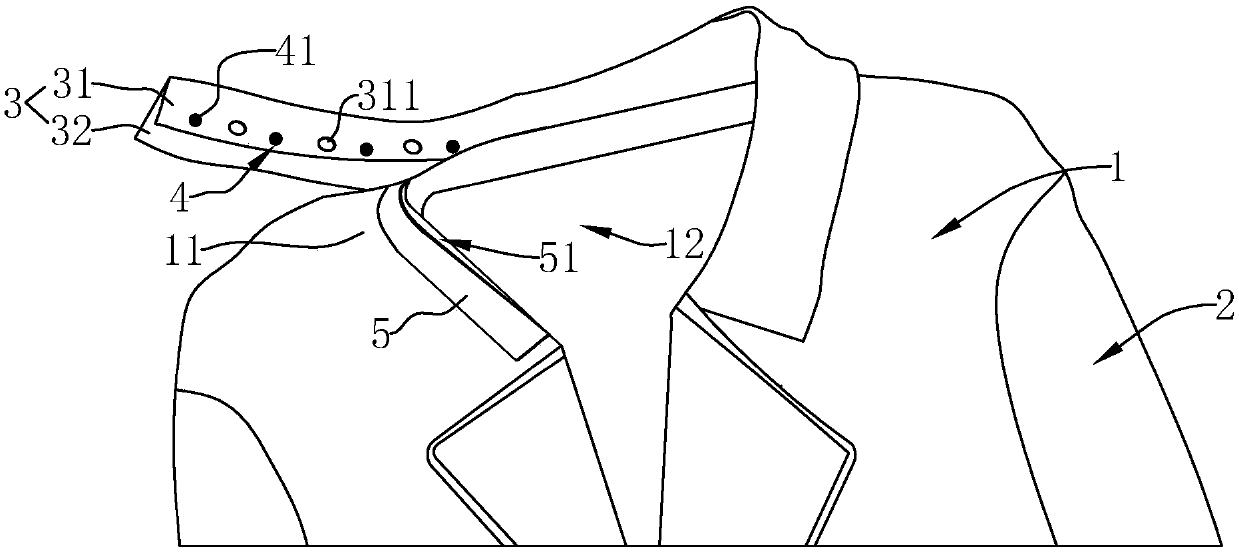

Coat of which collar support can be replaced and manufacturing technology of coat

PendingCN107927932AClosely connectedStable fastening with concealed buckleGarment special featuresOvergarmentsManufacturing engineeringIndustrial engineering

The invention discloses a coat of which a collar support can be replaced. According to the technical scheme, the coat is characterized by comprising a coat body, sleeves connected to the coat body anda collar, the collar comprises a collar base which is connected with the coat body through a fixing part and the collar support which is integrally formed on the collar base, a collar-shielding lining is sewed at a collar office close to the coat body, a collar groove covering the collar base is formed by the collar-shielding lining and the coat body, a connection opening is formed in the collarbase, and a connection part which can penetrate through the connection opening is arranged on the collar-shielding lining and the coat body. The invention further discloses a manufacturing technologyof the coat of which the collar support can be replaced. The manufacturing technology of the coat of which the collar support can be replaced comprises the steps of manufacturing the collar and manufacturing the collar-shielding lining, wherein the step of manufacturing the collar comprises the procedures of manufacturing a collar surface and a collar bottom, sewing the collar surface and the upper opening of the collar bottom, sizing the collar, sewing hidden buttons on the coat body and the collar, tailoring the connection opening on the collar and sewing the collar, and the step of manufacturing the collar-shielding lining comprises the procedures of manufacturing the collar-shielding lining, sewing buttons at the portion, close to the collar office, on the collar-shielding lining and the coat body, and sewing the collar-shielding lining to the collar office of the coat body. The sewed hidden buttons for shielding the coat body can better shield the junction of the collar and the coat body.

Owner:北京亿都川服装集团有限公司

Environment-friendly indoor wall finishing method

ActiveCN109898765AHas adsorption capacityImprove adsorption capacityCovering/liningsDispersed particle separationSalicylic acidHuman health

The invention relates to the field of wall finishing methods, and provides an environment-friendly indoor wall finishing method for the problem that as for a wall coating, harmful gas is not prone toemitting. The environment-friendly indoor wall finishing method includes the following steps that S1, an environment-friendly coating is prepared; S2, the environment-friendly coating is uniformly painted to the outer surface of the wall surface; and S3, the environment-friendly coating is scraped, and the environment-friendly coating is prepared from the following components in parts by mass: 8-10 parts of nano-micropore activated silica, 0.1-0.5 part of a silane coupling agent, 50-70 parts of calcium carbonate, 70-80 parts of cement, and 8-10 parts of salicylic acid. By adding the nano-micropore activated silica, the nano-micropore activated silica has the ability to adsorb various substances, especially for formaldehyde, toluene and other indoor harmful gas, the high adsorption capacityof the nano-micropore activated silica is achieved, as for the indoor wall surface, the harmful gas is not prone to emitting and consequently the human health is affected, and meanwhile, adsorption of the harmful gas emitted by oil paints and coatings on other indoor furniture or components is further facilitated.

Owner:GUANGZHOU NO 4 DECORATION CO LTD

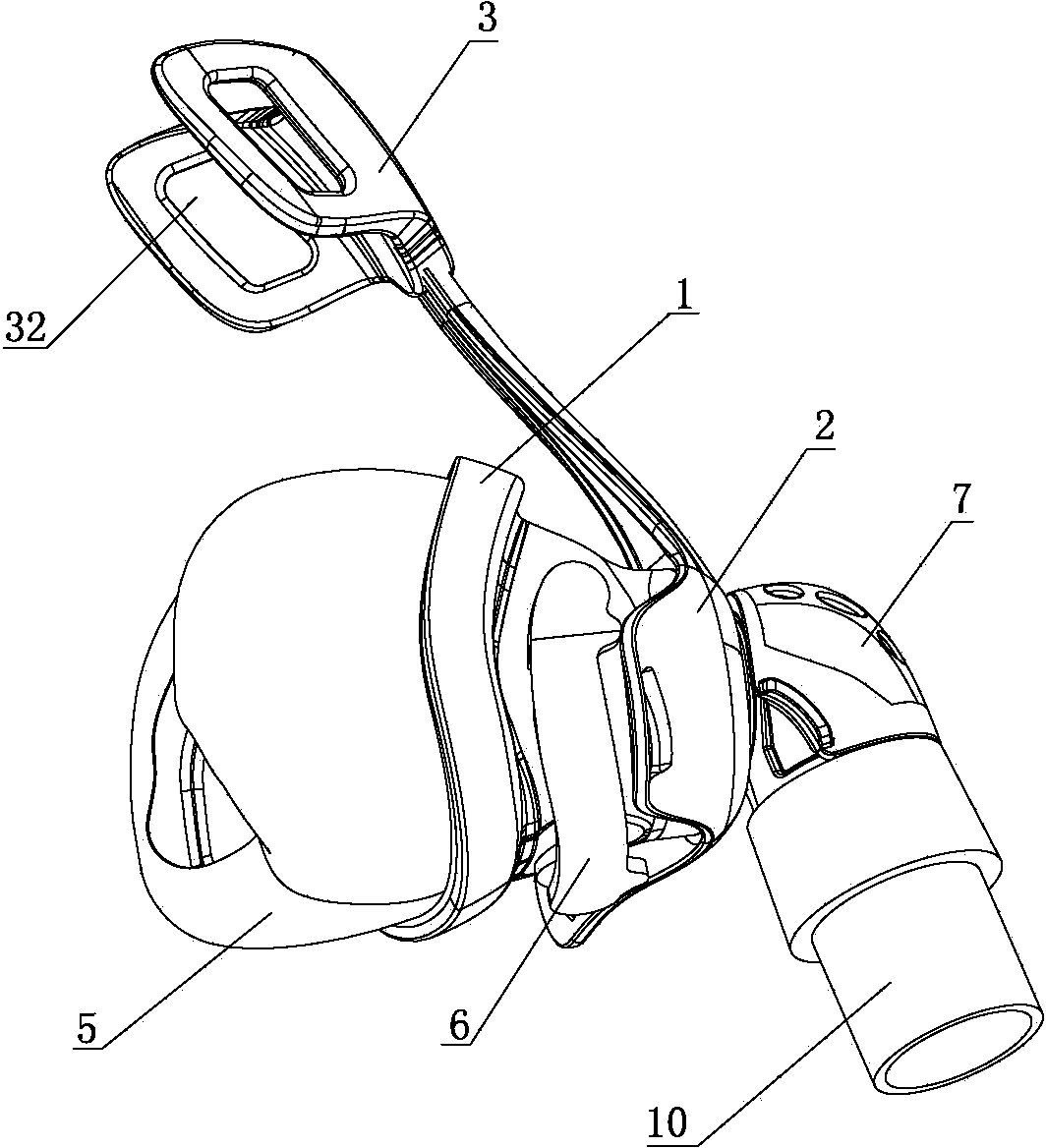

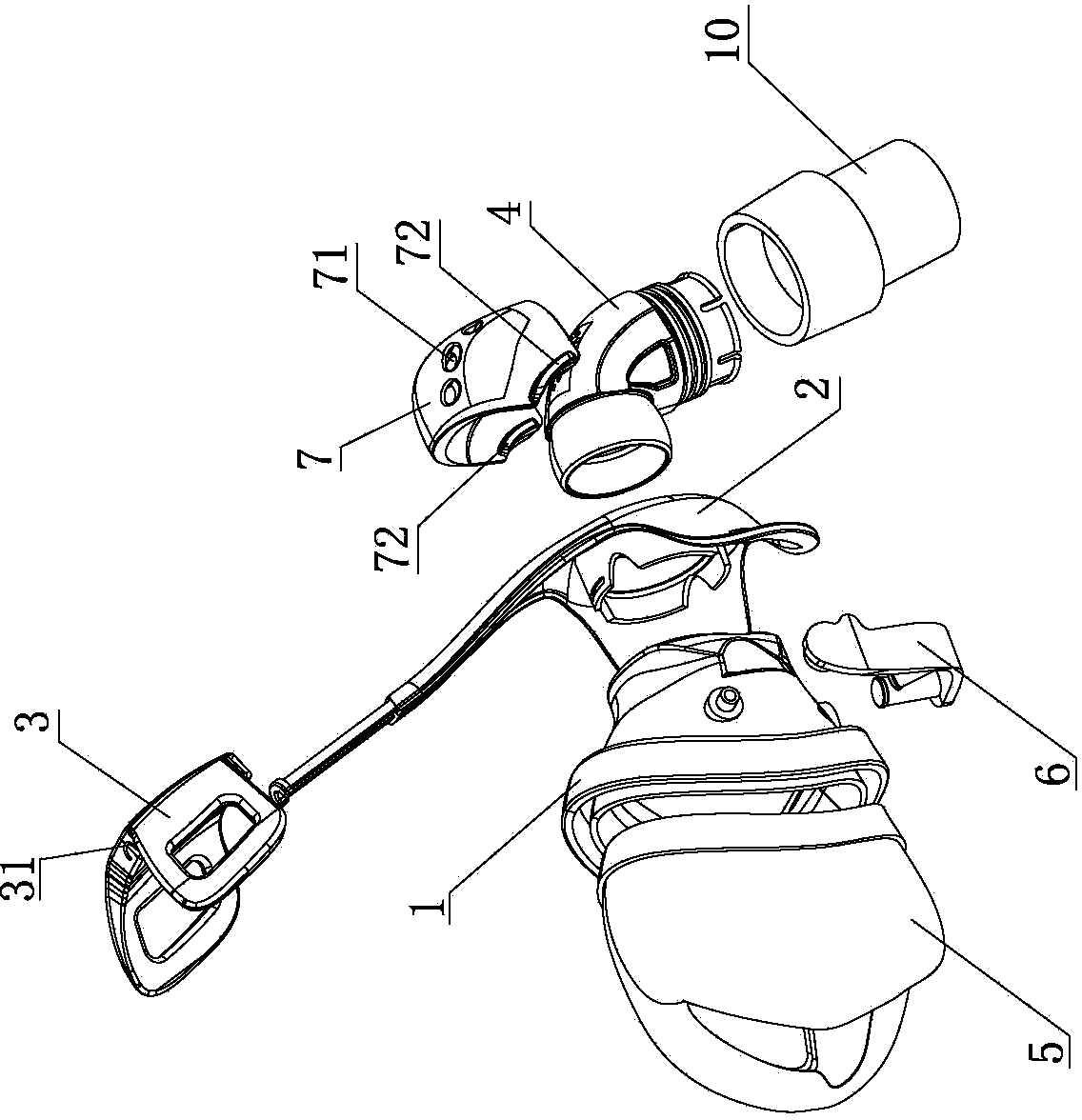

Nasal mask with nasal feeding tube channel

ActiveCN104107494AEasy to installEasy accessRespiratory masksFeeding-tubesAssistive device/technologyNose

The invention relates to the technical field of medical auxiliary equipment, in particular to a nasal mask with a nasal feeding tube channel. The nasal mask comprises a mask body, a forehead bracket arranged at the back end of the cover body, a forehead cushion arranged at the upper end of the forehead bracket, a respiration elbow arranged at the back end of the forehead bracket, and a nasal sleeve detachably connected to the front end of the mask body, wherein the bottom surface of the mask body is provided with a nasal feeding tube hole; the mask body is provided with a sealing part for sealing the nasal feeding tube hole. By adopting the nasal mask with the nasal feeding tube channel, a corresponding nasal sleeve can be selected according to the nose size of a patient, the feeling of the patient is considered comprehensively, and the patient feels comfortable. Through the nasal feeding tube hole, convenience is brought to the treatment, feeding, administration and the like of the patient wearing the nasal mask. The nasal mask has very high practicability.

Owner:李涛平

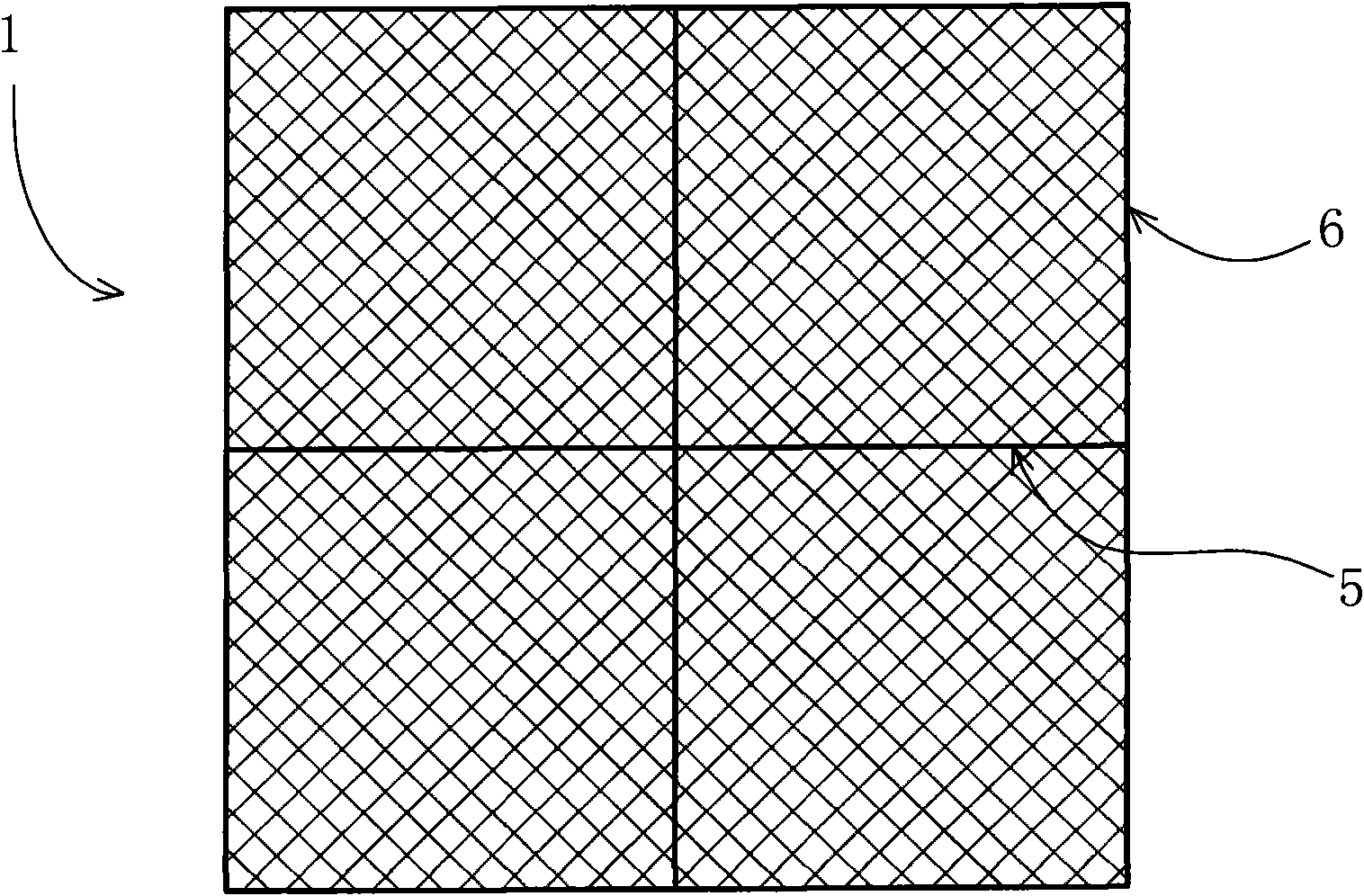

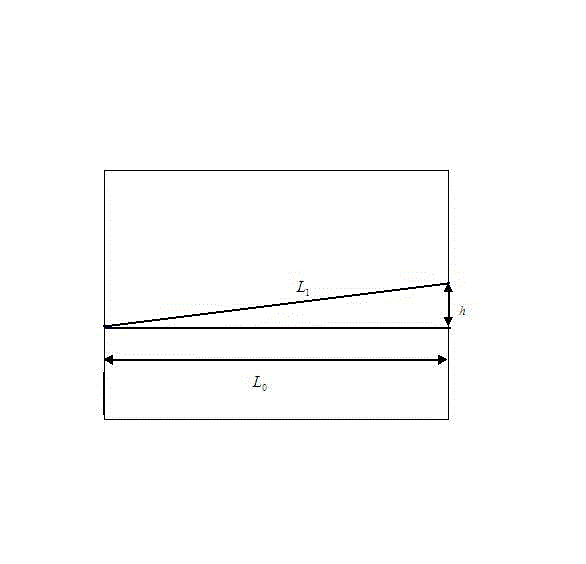

Fabric with small bias filling rate for airbag

ActiveCN102978781ASmall inclinationImprove tearabilityPedestrian/occupant safety arrangementWoven fabricsFilling rateEngineering

A fabric with a small bias filling rate for an airbag is characterized by consisting of a ground stitch and selvage stitches positioned on two sides of the ground stitch, wherein the ground stitch and the selvage stitches are formed by adopting two kinds of filaments with different initial moduluses; the difference ratio of the initial modulus of high initial modulus filaments for the ground stitch to the initial modulus of low initial modulus filaments for the selvage stitches is 15.0-40.0 percent; and the small bias filling rate of the fabric is not more than 2.0 percent. The fabric for the air bag, which is disclosed by the invention, has the advantages of small bias filling rate, excellent tensile failure and tearing property, favorable size stability and low cost.

Owner:KOLON NANJING SPECIAL TEXTILE

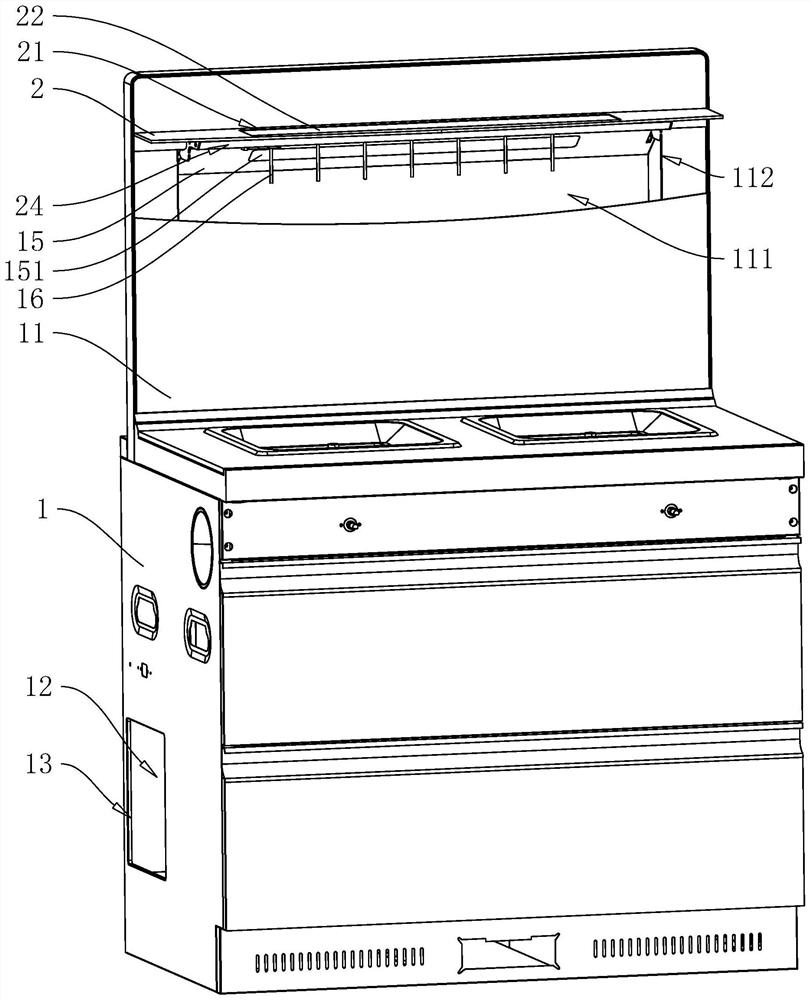

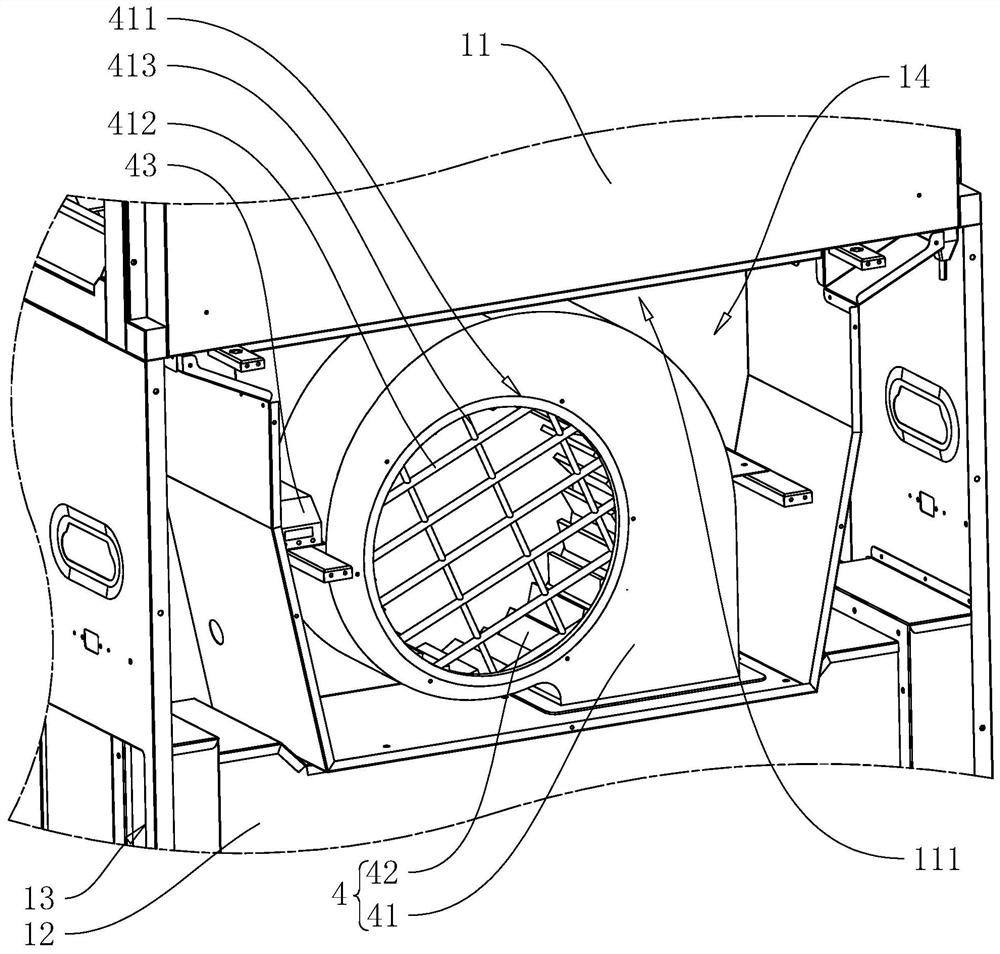

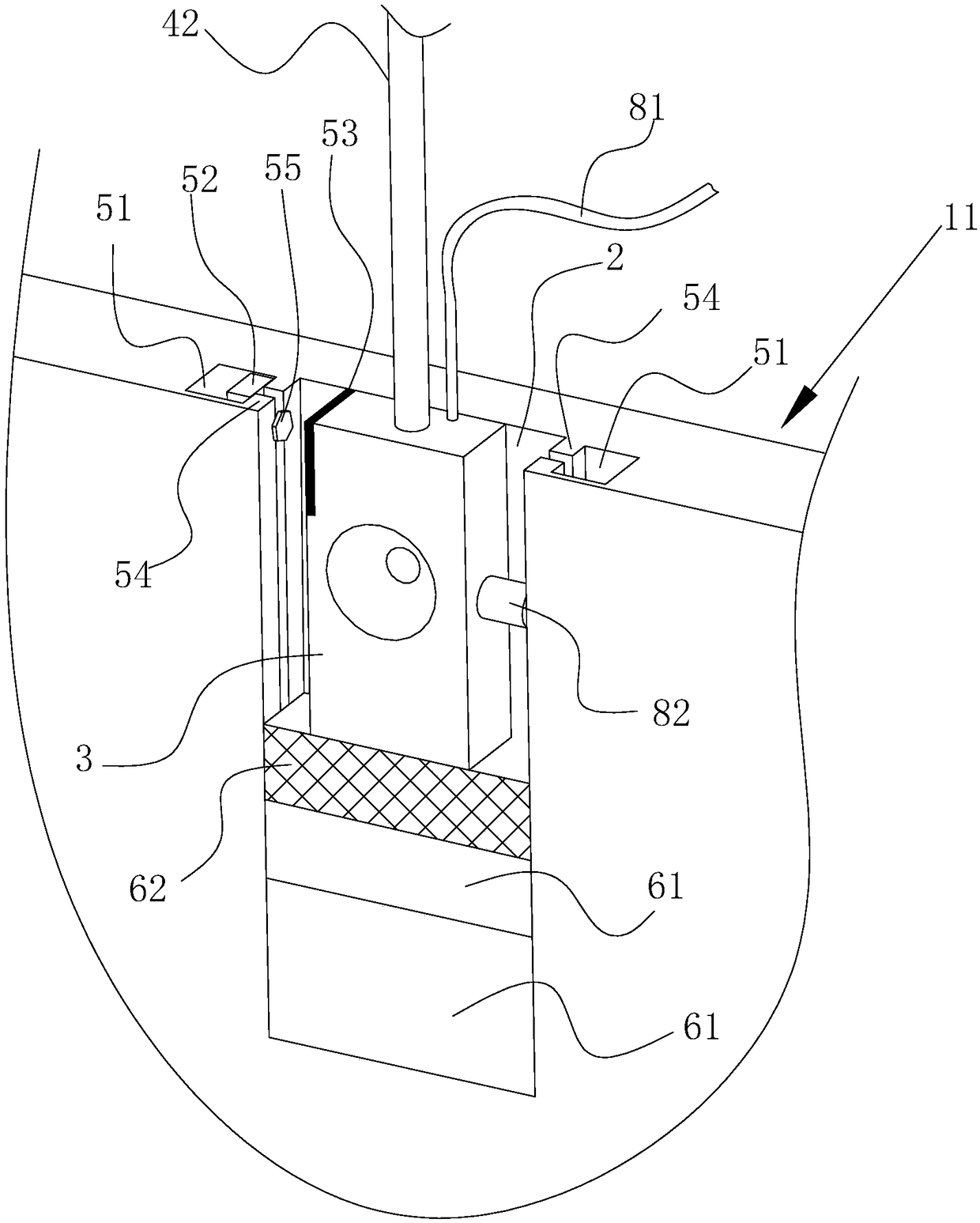

Integrated stove

InactiveCN113217964AReduce spreadImprove absorption efficiencyDomestic stoves or rangesLighting and heating apparatusThermodynamicsEngineering

The invention relates to an integrated stove. The integrated stove comprises a mounting cabinet used for mounting a gas stove, a mounting plate is arranged on the top wall of the mounting cabinet, a smoke suction channel is formed in the mounting plate, a smoke suction opening is formed in the side wall of the mounting plate and connected with the smoke suction channel, a smoke exhaust mechanism is arranged in the mounting cabinet and connected with the smoke suction channel, a smoke exhaust channel is arranged in the mounting cabinet and connected with the smoke exhaust mechanism, and a smoke outlet is formed in the side wall of the mounting cabinet and connected with the smoke exhaust channel. The stove is provided with the smoke exhaust mechanism, the smoke exhaust port formed in the side wall of the mounting plate is used for absorbing and exhausting relatively-concentrated oil smoke in the contraction rising area, so that the oil smoke is absorbed and exhausted when not diffused, the oil smoke absorption efficiency is improved, the oil smoke diffused into air in a kitchen is reduced, the environment in the kitchen is purified, the amount of the oil smoke inhaled by a cook is reduced, and the body health effect of the cook is protected.

Owner:绍兴市永辉电器有限公司

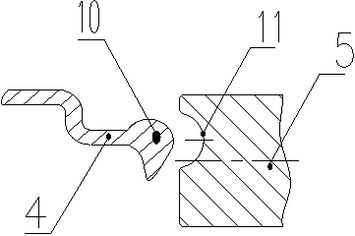

Improved creasing and cutting machine

ActiveCN108724302ANot easy to foldReduce the chance of being clampedMetal working apparatusEngineeringMechanical engineering

The invention discloses an improved creasing and cutting machine. According to the technical scheme, the improved creasing and cutting machine comprises a machine frame, a fixed plate fixed to the machine frame and a turning plate which is in press fit with the fixed plate rotatably. The improved creasing and cutting machine further comprises a sliding groove, a suction disc, a lifting assembly and a pushing assembly, wherein the sliding groove is vertically formed in the fixed plate, and a notch of the sliding groove faces the turning plate; the suction disc is arranged in the sliding groove,the suction disc penetrates through the notch of the sliding groove to realize the suction with paper; the lifting assembly is fixed to the suction disc and drives the suction disc to enter and exitthe sliding groove; and the pushing assembly drives the lifting assembly to reciprocate transversely so as to move the suction disc separated from the sliding groove out of the extrusion position between the fixed plate and the turning plate, so that the purposes of improving the production efficiency is achieved, the occurrence of safety accidents is reduced, and the improved creasing and cuttingmachine is more environment-friendly.

Owner:深圳市益华兴包装制品有限公司

rainproof suitcase

ActiveCN106963078BExtended service lifeAvoid dirtyLuggageOther accessoriesEngineeringMechanical engineering

The invention discloses a rainproof luggage case which comprises a case body, a base and a rolling ball. The case comprises a base plate, a first pair of side plates, a second pair of side plates and an extending portion, wherein the first pair of side plates and the second pair of side plates are upwards arranged along the base plate and are hinged to the base plate, one end of the extending portion can be connected to one of the first pair of side plates through a rolling shaft in a rolled or stored mode, the other end of the extending portion is fixed to the other one of the first pair of side plates, a sliding portion is also arranged at the lower end of the other one of the first pair of side plates, a sliding groove matched with the sliding portion is formed in the base plate, the sliding portion can move along the sliding groove, and the second pair of side plates is made of a flexible material. The base is arranged at the bottom of the base plate and comprises a first arc-shaped seat and a second arc-shaped seat which are connected mutually, the first arc-shaped seat and the second arc-shaped seat form a cavity, and an opening is formed in the lower portion of the cavity. The rolling ball is comprehensively arranged in the cavity in a rolling mode and corresponds to the base in a one-to-one mode, part of rolling ball is exposed out of the opening, and the diameter of the rolling ball is greater than the inner diameter of the opening.

Owner:浙江敏宇新材料股份有限公司

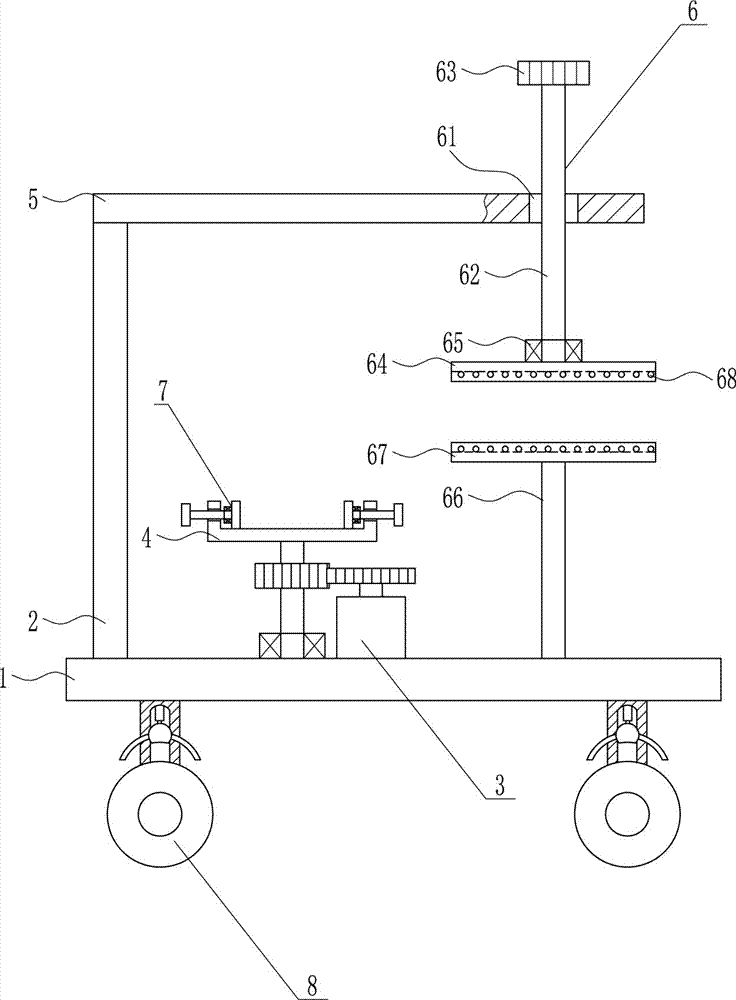

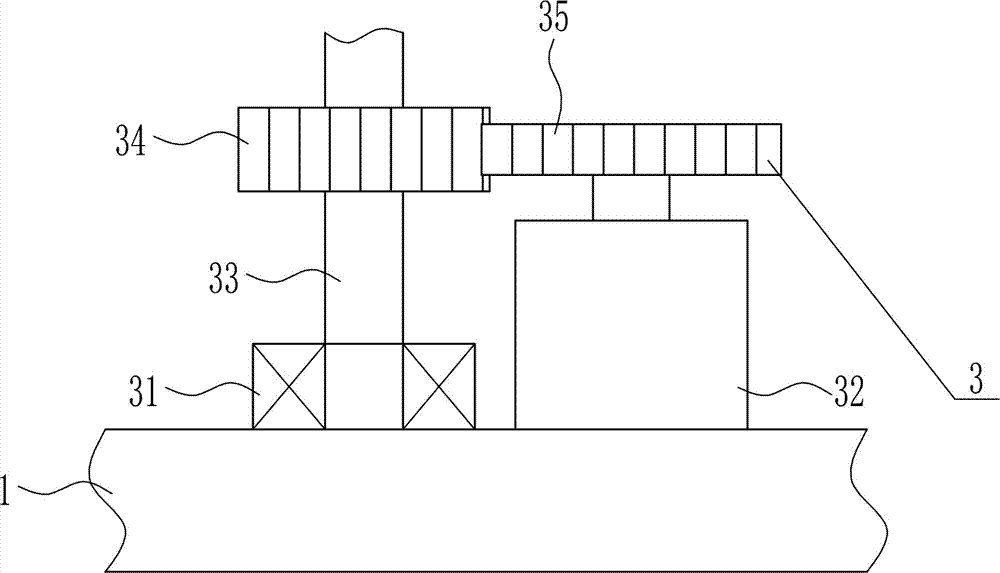

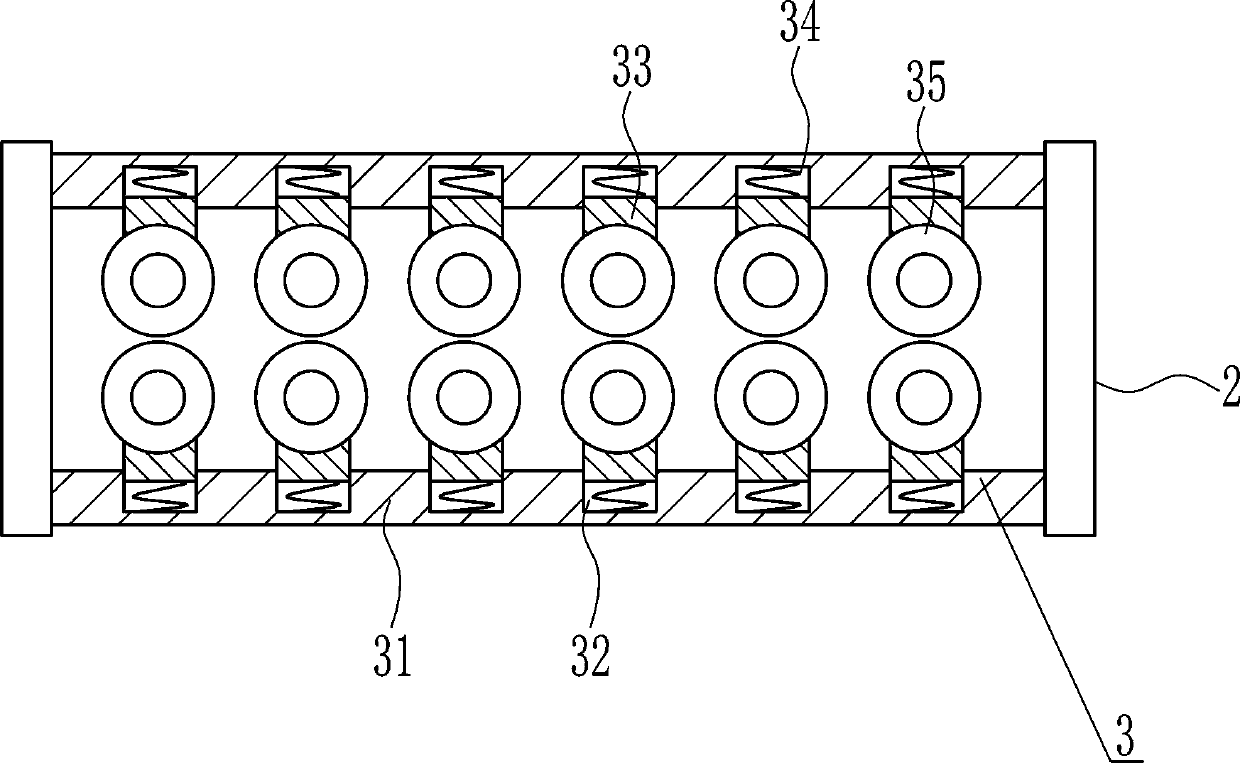

Automatic winding device for well cable for electric power engineering construction

InactiveCN107500024ANot easy to foldImprove the winding effectFilament handlingEngineeringUltimate tensile strength

The invention relates to a cable winding device, in particular to an automatic winding device for a well cable for electric power engineering construction. The invention aims to solve the technical problems that time and labor are wasted, labor intensity is high, and working efficiency is low. In order to solve the technical problems, the automatic winding device for the well cable for electric power engineering construction is provided. The automatic winding device for the well cable for electric power engineering construction comprises a bottom plate, a support is vertically mounted at the left end of the top of the bottom plate in a bolt connection mode, the top of the support is horizontally connected with a top plate in a bolt connection mode, a guide device is arranged between the right of the top plate and the right of the bottom plate, and a rotating device is arranged at the top, between the guide device and the support, of the bottom plate. Guidance is conducted through a first transverse plate and a second transverse plate, so the cable is not prone to winding or folding in the cable winding process, the winding effect is good, and the effects of saving time and labor and being low in labor intensity and high in working efficiency are realized.

Owner:喻杨凯

Double-wheel-set different-axis pressurizing mechanism for hot air welding machine and working method and using method of mechanism

The invention belongs to the technical field of hot melting welding, and particularly relates to a double-wheel-set different-axis pressurizing mechanism for a hot air welding machine and a working method and a using method of the mechanism. The mechanism comprises upper and lower belt wheel rotating synchronously and feeding and discharging wheels rotating synchronously; the synchronous rotatingspeed of the upper and lower belt wheels is V1, and the synchronous rotating speed of the feeding and discharging wheels is V2; and V2<=V1. According to the working method, the feeding wheel, the discharging wheel, the upper belt wheel and the lower belt wheel form a double-wheel-set structure and then rotate synchronously or differentially, and pressure conveying of a wiredrawing cloth, an upperedge covering belt and a lower edge covering belt is achieved. According to the using method, the upper edge covering belt, the lower edge covering belt and wiredrawing cloth penetrate into an inlet of the pressurizing mechanism, the upper belt wheel, the lower belt wheel, the feeding wheel and the discharging wheel rotate, and pressurizing conveying of the wiredrawing cloth, the upper edge covering belt and the lower edge covering belt is achieved. V2 is smaller than or equal to V1, the upper edge covering belt, the lower edge covering belt and the wiredrawing cloth are synchronously pressurized and conveyed, and materials are easy to turn round corners. The wiredrawing cloth is not prone to slipping due to resistance, the inner side section of the wiredrawing cloth is prevented from moving out of the upper and lower edge covering belts, welding is not prone to folding, and the welding quality is improved.

Owner:CHANGZHOU RUFA MACHINERY CO LTD

Non-silicon release agent for aluminum foil adhesive tape

PendingCN109535796AGood release effectEasy to useAnti-corrosive paintsElectrically-conductive paintsCyclohexanoneFiber

The invention relates to the technical field of adhesive tapes, and provides a non-silicon release agent for an aluminum foil adhesive tape against the problem of easy corrosion of non-silicon releaselayers. The non-silicon release agent comprises, by mass, 0.75-1 part of octadecyl acrylate, 102-136 parts of toluene, 21-28 parts of cyclohexanone, 4.5-6 parts of isocyanate, 0.45-0.6 part of ammonium alcohol ether sulphate, 0.45-0.6 part of carbon fibers and 0.45-0.6 part of a coupling agent. The addition of the carbon fibers is helpful for enhancing the corrosion resistance of the non-siliconrelease agent, so the non-silicon release layer is not prone to be corroded, thereby the protection of the aluminum foil adhesive tape by the non-silicon release layer is benefited; the addition of the ammonium alcohol ether sulphate is helpful for enhancing the antistatic property of the non-silicon release layer; and active hydrogen of an amino group on the ammonium alcohol ether sulphate can beeasily reacted with isocyanate to make molecular chains intertwined, so the formation of a crosslinked network between molecules is benefited to enhance the strength of the non-silicon release agent,thereby good protection of the aluminum foil adhesive tape by the non-silicon release layer is benefited.

Owner:常州市白鹭电器有限公司

Embroidering device

ActiveCN108179560ASimple structureEasy to installAutomatic machinesAuxillary devicesEngineeringMechanical engineering

The invention discloses an embroidering device. The embroidering device comprises a needle bar box arranged on an embroidery machine body and a material delivering device matched with the needle bar box, wherein a needle bar is fixed in the needle bar box; the material delivering device is sequentially provided with a discharging mechanism for fixing a material embroidering position, a guiding mechanism for guiding the direction and the position of the material as well as a retracting mechanism which is positioned in the delivering direction of the material and is used for delivering the material from bottom to top. The embroidering device disclosed by the invention has the advantages of simple structure, easiness in mounting, reduced manual operation, improved production efficiency, smooth guiding of the material, low possibility of twisting or quilling, and the like.

Owner:田岛刺绣机械(中国)有限公司

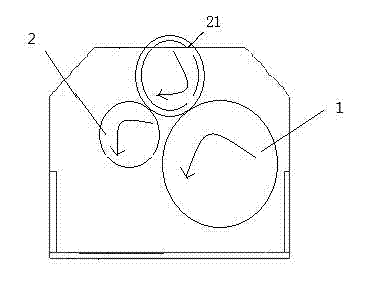

Net reel for papermaking forming net inspection

The invention discloses a net reel for papermaking forming net inspection. The net reel comprises a large roller and a small roller, wherein the large roller and the small roller are respectively driven by a large roller gear and a small roller gear; the large roller gear and the small roller gear are meshed with a driving gear; the driving gear is driven by a net reeling motor; the driving gear and the net reeling motor are connected through a motor coupler; the sizes of the large roller and the small roller are different; and the large roller and the small roller are different in linear velocity. Compared with the prior art, the forming net is rolled by employing the large roller and the small roller, and the two rollers have different linear velocities, so that a high reeling quality is achieved; and moreover, the linear velocity of the small roller is larger than that of the large roller, so that the forming net is densely reeled, and crease is difficultly generated.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

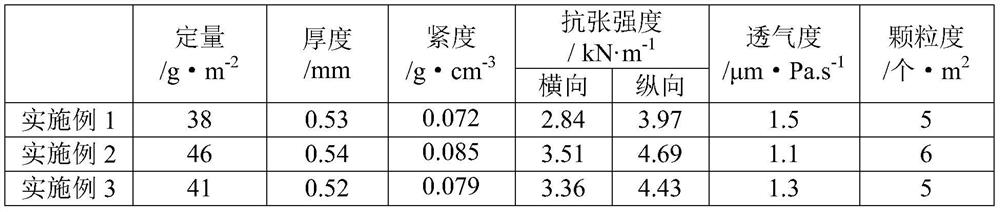

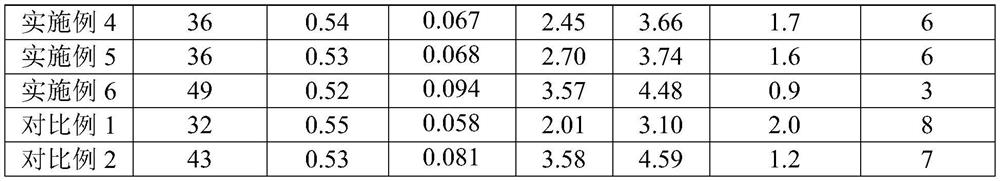

A kind of low air permeability ctp plate backing paper and preparation method thereof

ActiveCN111622017BReduce air permeabilityHigh grafting rateNon-fibrous pulp additionSpecial paperPapermakingSoftwood

The invention relates to the technical field of papermaking, and discloses a low air permeability CTP plate backing paper and a preparation method thereof. The raw materials of the CTP plate backing paper include softwood pulp, hardwood pulp, and polyhydroxy hyperbranched polymer; the mass ratio of the hardwood pulp to softwood pulp is 1:3~5; the polyhydroxy hyperbranched polymer The dosage is 1~1.5% of the total dry weight of softwood pulp and hardwood pulp. The CTP plate backing paper of the present invention has low air permeability, can be absorbed by vacuum suction cups, has high stiffness, and is not easy to be folded during the pick-and-place process, so it can better adapt to automatic paper pick-up by intelligent manipulators.

Owner:XIANHE CO LTD

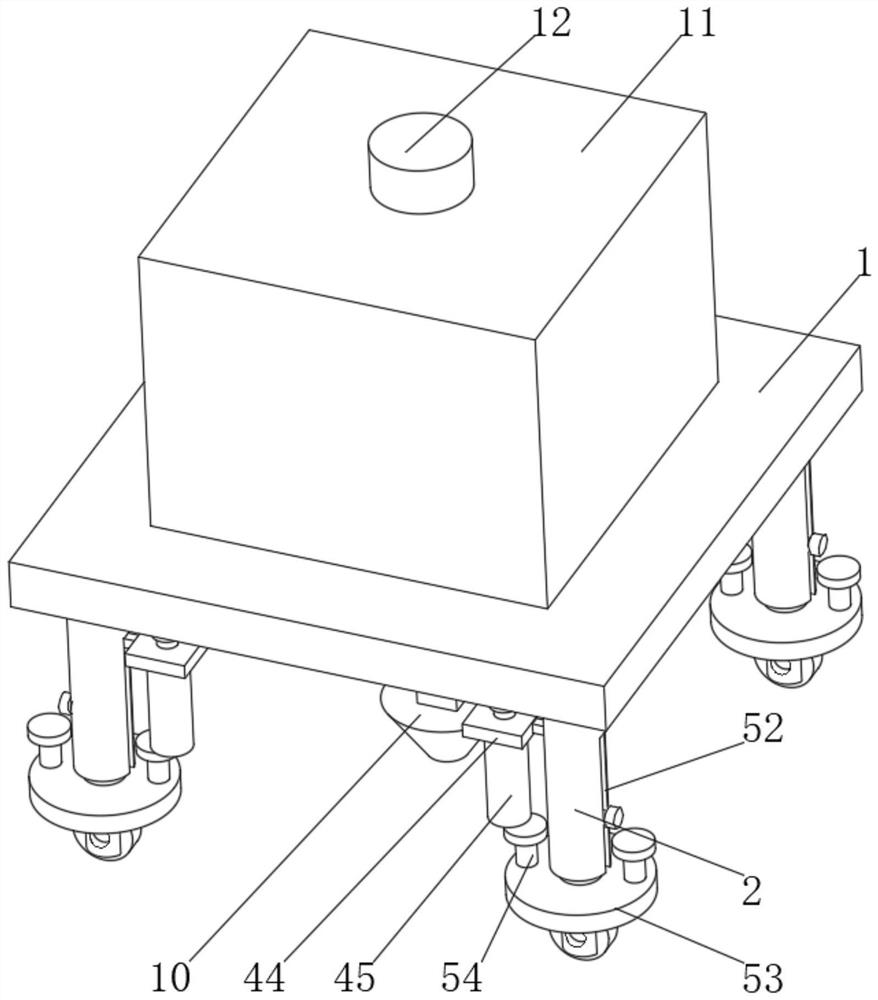

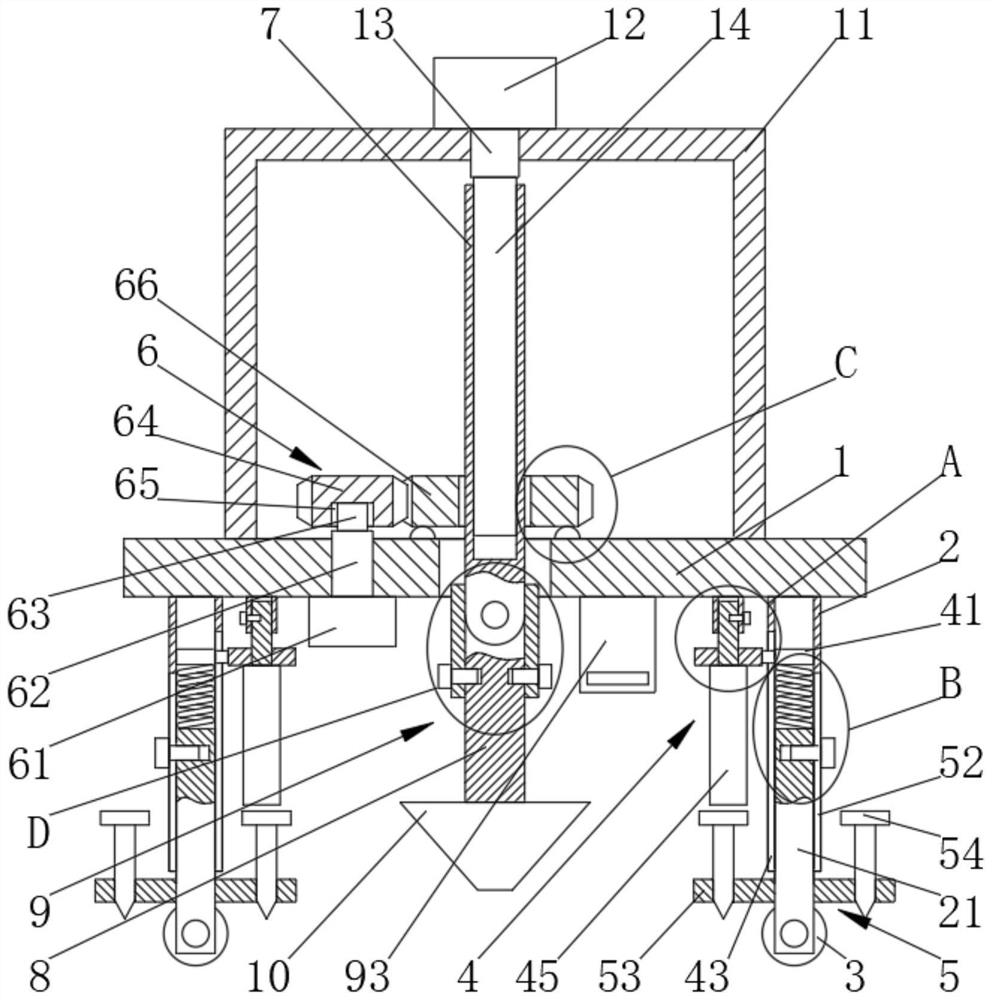

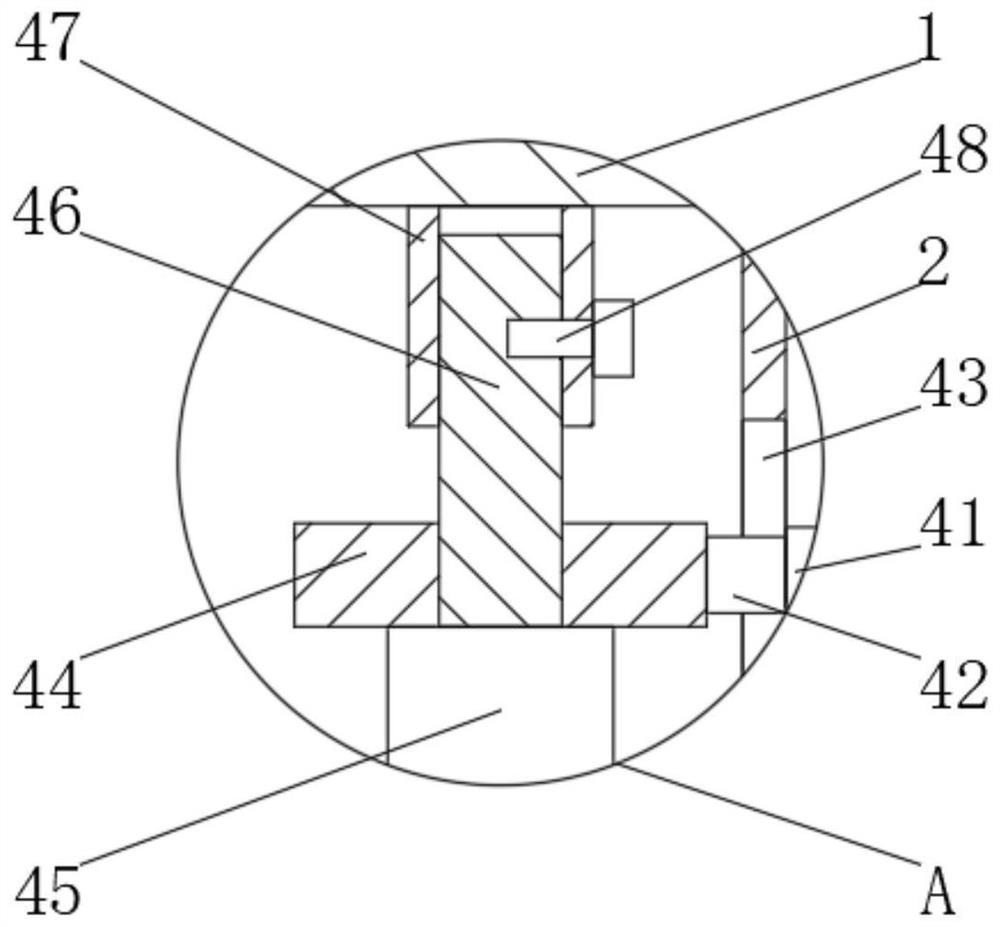

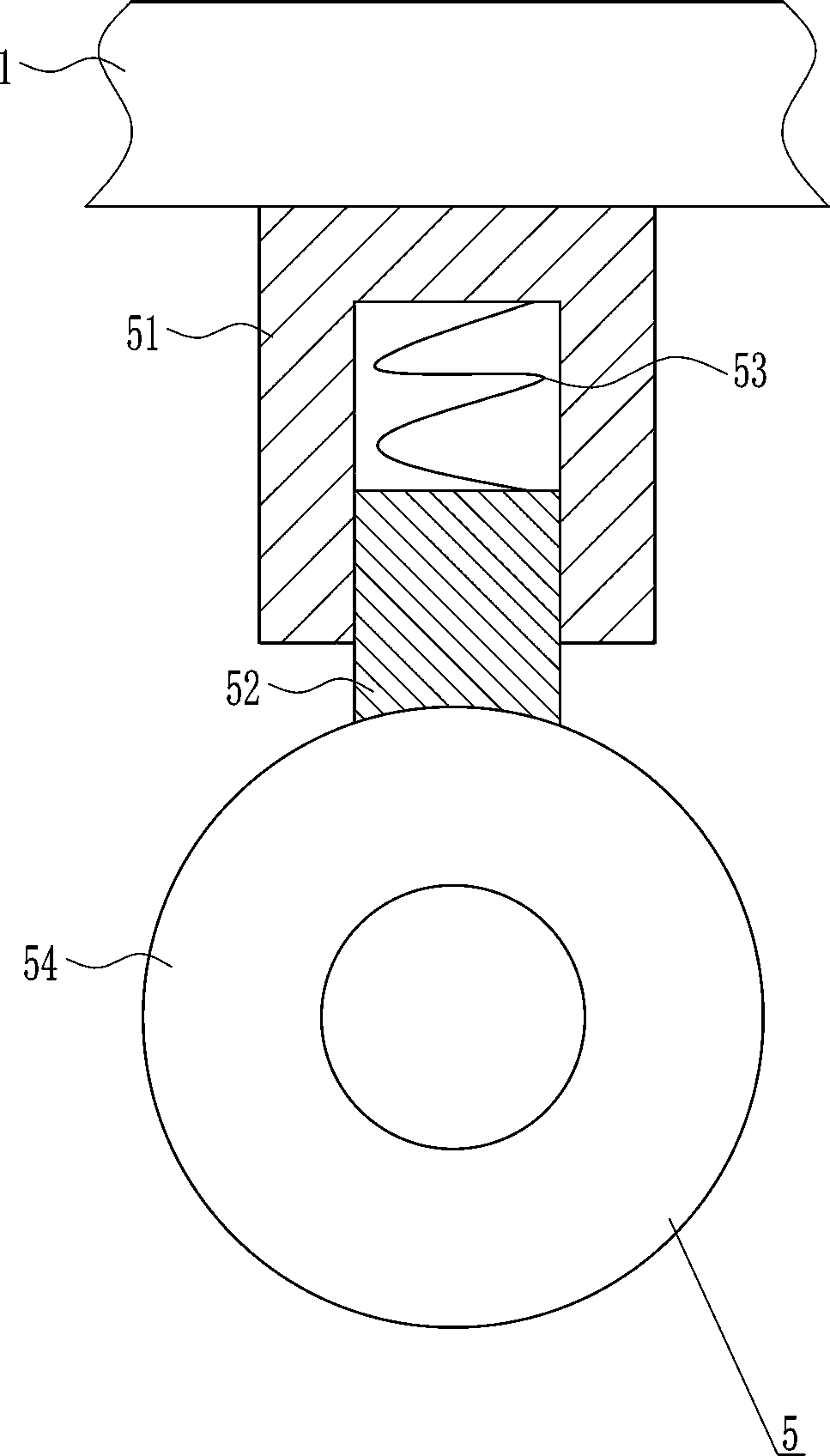

Geological survey device suitable for multiple terrains

PendingCN114088451APlace stableAvoid damageWithdrawing sample devicesWater resource assessmentTerrainMarine engineering

The invention discloses a geological survey device suitable for multiple terrains. The geological survey device comprises a bottom plate, a cylinder is welded on the bottom plate, and a support leg is slidably sleeved in the cylinder; wheels are arranged on the support leg, an adjusting mechanism is arranged on the bottom plate, and a fixing mechanism is arranged on the cylinder; a driving mechanism is arranged on the bottom plate, a frame is welded to the bottom plate, and a motor is fixedly installed on the frame; a rotating shaft of the motor is rotationally connected with the frame, a screw is welded to the rotating shaft, and a square cylinder is connected to the outer side of the screw through threads; a square rod is hinged to the square cylinder, the square cylinder is movably connected with the bottom plate, a limiting mechanism is arranged on the square rod, and a drill bit is fixedly installed on the square rod. The invention relates to the geological survey device suitable for multiple terrains. The geological survey device has the advantages that the geological survey device can be used on multiple terrains, and a drill bit can be folded and is not prone to collision.

Owner:SHENZHEN AIHUA RECONNAISSANCE ENG CO LTD

A dense-mesh net fast winding device for environmental protection on building construction sites

ActiveCN108100724BNot easy to foldFast winding speedWebs handlingArchitectural engineeringUltimate tensile strength

The invention belongs to the technical field of construction protection, and particularly relates to a dense screen rapid winding device for construction site environment protection. The dense screenrapid winding device for construction site environment protection is easy to operate, convenient to use and capable of saving time and labor and reducing labor intensity. In order to achieve the technical aims, the dense screen rapid winding device for construction site environment protection comprises a bottom plate and the like; supports are vertically arranged on the top of the bottom plate ina bilateral symmetry manner, a guide device is arranged on the lower portion of the position between the two supports, and a winding device is arranged on the upper portion of the position between thetwo supports. A front pulley and a rear pulley are arranged, the phenomenon that in the winding process, a dense screen is not prone to winding is avoided, winding speed is improved, and the effectsof being simple in structure, convenient to use and capable of saving time and labor and reducing labor intensity are achieved.

Owner:南通永固建设有限公司

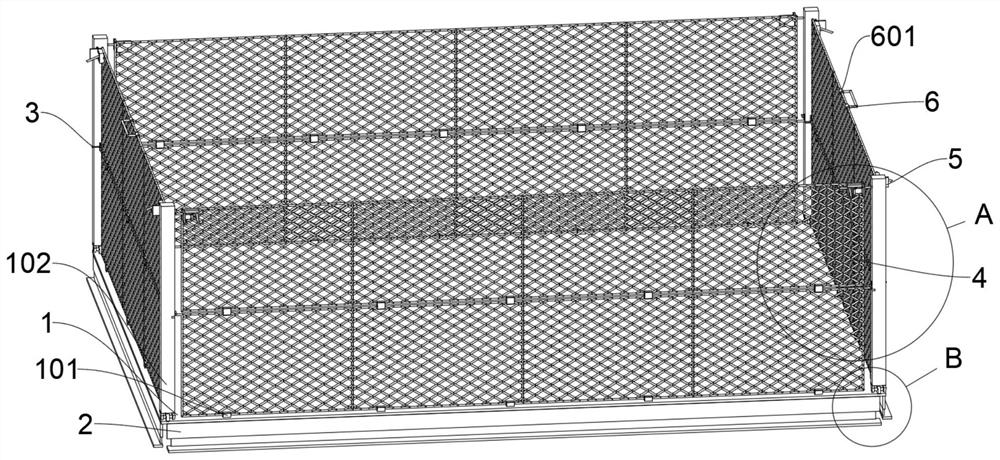

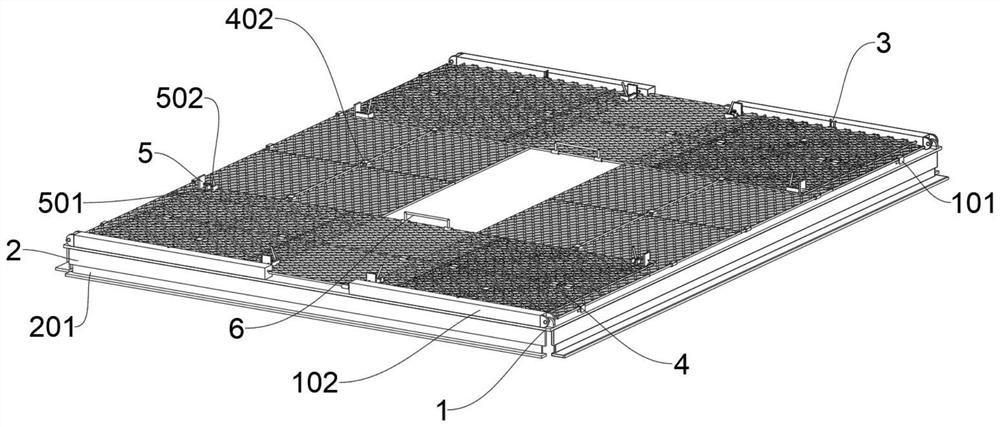

Foldable carrying net cage structure based on marine transportation engineering

InactiveCN113003012APrevent labor increaseAvoid wear and tearLarge containersMarine engineeringStructural engineering

The invention provides a foldable carrying net cage structure based on marine transportation engineering, and relates to the technical field of marine transportation engineering. The foldable carrying net cage structure aims to solve the problems that an existing foldable carrying net cage structure based on marine transportation engineering does not have the limiting and shaping effects, cannot ensure the safety of goods and the labor efficiency, and affects the time of the whole operation process; the existing foldable carrying net cage structure does not have the rotating and protecting capability, and cannot ensure the usability of the device due to the fact that goods wear parts; and the existing foldable carrying net cage structure does not have the self-locking capability, and is inconvenient to disassemble, assemble and assemble. The foldable carrying net cage structure comprises a main plate, wherein supporting rods are fixedly arranged at the end corners of the top of the main plate; telescopic plates are fixedly arranged at the bottom of the main plate; grooves are formed in the middles of the supporting rods, and pressing plates are fixedly arranged in the grooves; a grid plate is rotationally arranged at the top of the main plate; a plurality of sets of fixing plates are fixedly arranged at the end part of the top of the grid plate; and a handle is rotationally arranged on a cross rod at the top of the grid plate.

Owner:陈九銮

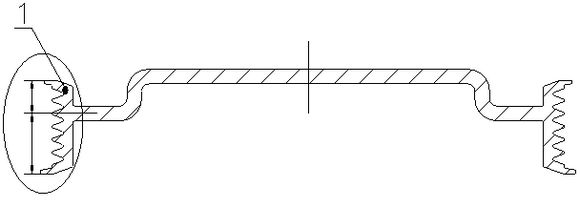

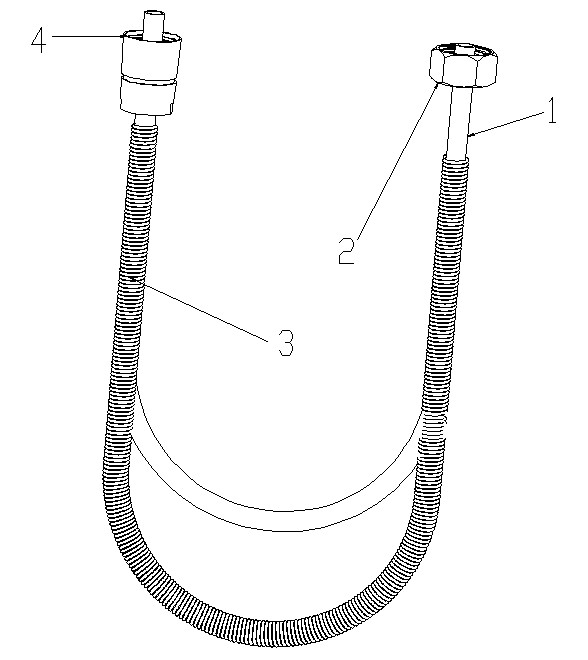

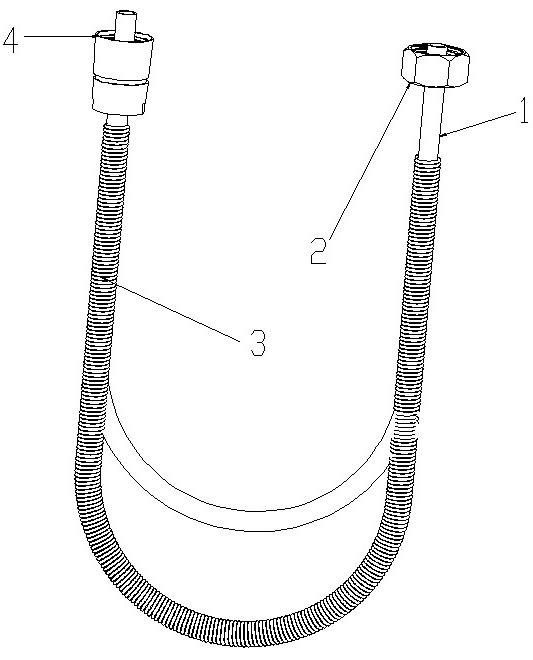

Hose of shower head

InactiveCN102644809AEasy to installStrong reliabilityFlexible pipesPipe protection against damage/wearEngineeringShower

The invention relates to a hose of a shower head, comprising a hose main body, wherein one end of the hose main body is connected with a collar nut, and the other end of the hose main body is connected with a shower head casing joint; a spring hose is arranged outside the hose main body; and the spring hose surrounds the outside of the hose main body. The hose and the spring hose can be elongated; and the hose of a shower head is simple and convenient in installation, good in tensile property, practical and beautiful, and strong in reliability.

Owner:汪洋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com