Improved creasing and cutting machine

A thread cutting machine and indentation technology, applied in the field of packaging paper cutting equipment, can solve problems such as hand pinching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

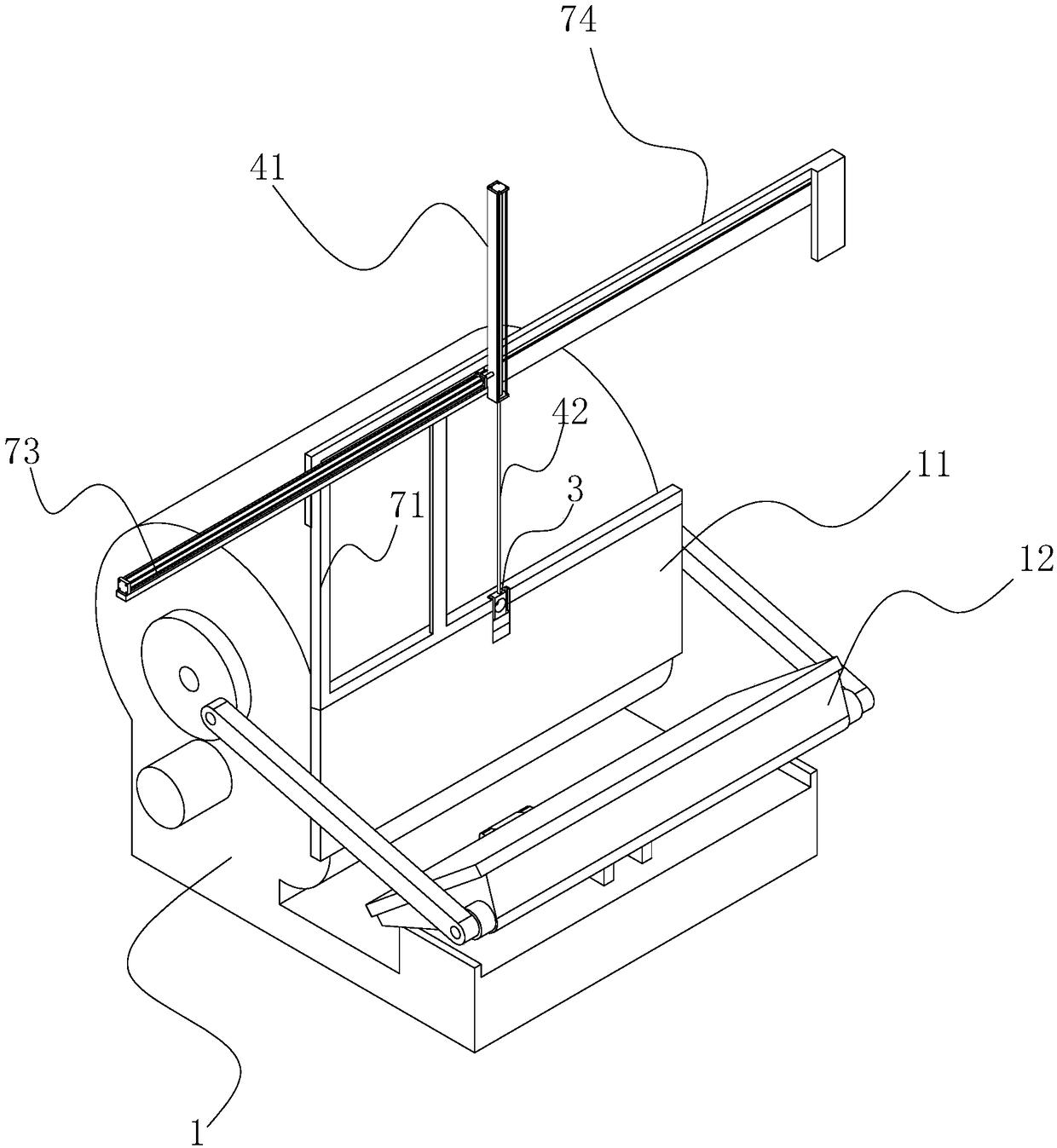

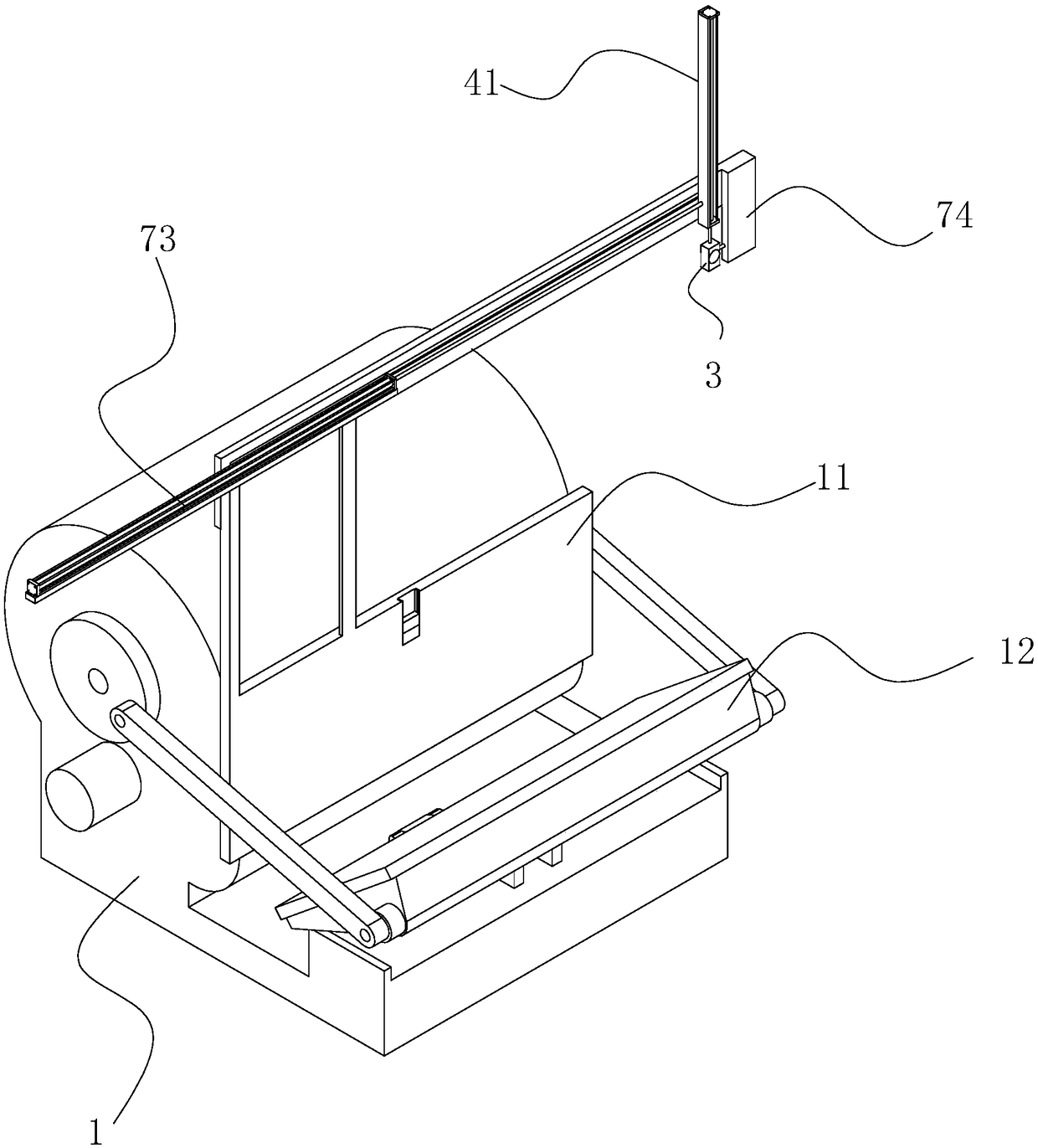

[0059] Embodiment 1, an improved creasing and thread cutting machine, as shown in Figure 1, includes a frame 1, a fixed plate 11 and a flap 12 are installed on the frame 1, and the flap 12 is rotationally connected with the main body of the frame 1, and the frame The crank mechanism on 1 drives the turning plate 12 to perform repeated pressing and opening actions towards the fixed plate 11; during this operation, the cutter mold will be placed in the fixed plate 11, and the staff will put the paper into the turning plate 12, A supporting member made of soft material is placed in the turning plate 12, and the paper is placed on the supporting member, and then the paper is cut by the cutter mold on the fixed plate 11 as the turning plate 12 rotates.

[0060] It can be seen that the upper end of the fixed plate 11 is fixed with a column 71 , and there are two columns 71 ; the upper ends of the two columns 71 are fixed with a horizontal slide rail 74 . The track line of slide rail...

Embodiment 2

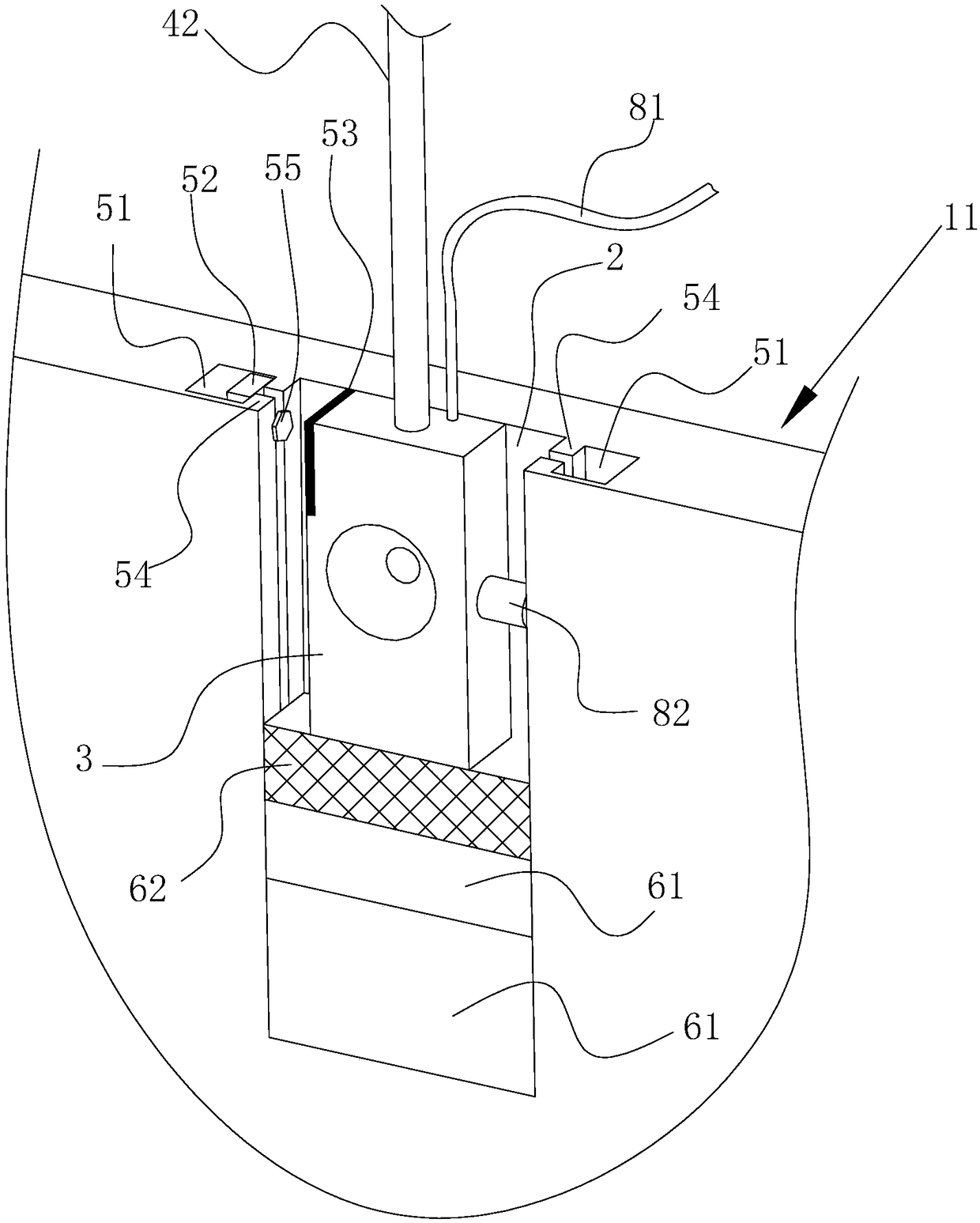

[0075] Embodiment 2, improved creasing and cutting machine, such as figure 2 and image 3 As shown, one side of the suction cup 3 is provided with a branch pipe 82, and the branch pipe 82 communicates with the air flow channel inside the suction cup 3. When the air pipe 81 urges the air flow passage in the suction cup 3 to inhale, due to the sealing of the branch pipe 82, the suction cup 3 has good airflow. of suction.

[0076] And be placed on frame 1 outer side on slide rail 74 and be fixed with block 74, block 74 is used for blocking vertical cylinder 41, prevents vertical cylinder 41 from slipping out slide rail 74; Of course, block 74 also has a function Just trigger branch pipe 82, make branch pipe 82 air leakage, then paper will lose the suction force of suction cup 3, and paper will fall freely.

[0077] As shown in FIG. 4 , the branch pipe 82 communicates with the inside of the suction cup 3 , and a spherical valve core 84 is installed in the branch pipe 82 . Unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com