A kind of low air permeability ctp plate backing paper and preparation method thereof

A kind of gas and lining paper technology, which is applied in the field of low air permeability CTP plate lining paper and its preparation, can solve the problems of high air permeability of CTP plate lining paper, inability to adapt to automatic production lines, low air permeability, etc. The effect of folding and reducing air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

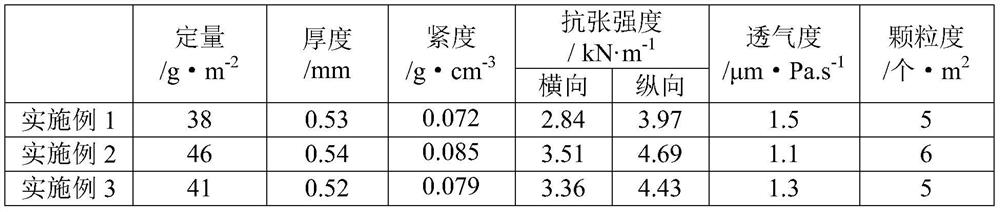

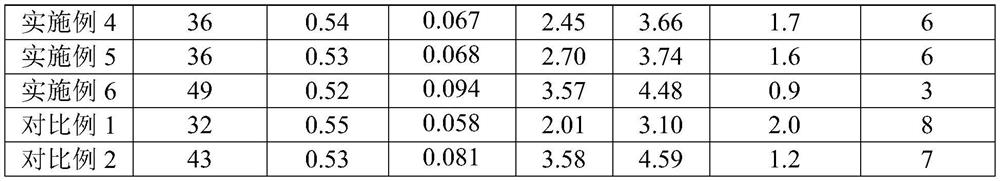

Embodiment 1

[0048] Prepare a CTP plate backing paper by the following method:

[0049] (1) prepare polyhydroxyl hyperbranched polymer:

[0050] (1.1) Under the protection of an inert gas, drop the dimethylacetamide solution of pyromellitic dianhydride into the dimethylacetamide solution of 2,2'-dihydroxydipropylamine, fully react until the cyclic anhydride The characteristic peaks disappeared; after the reaction, toluene was added to precipitate the reaction product, filtered, and the filter residue was rotary evaporated to obtain the product; the mass ratio of the above-mentioned pyromellitic dianhydride to 2,2'-dihydroxydipropylamine was 1:4.1;

[0051] (1.2) Mix the product obtained in step (1.1), glyceric acid, and p-toluenesulfonic acid in a mass ratio of 1:400:8.02, add p-toluenesulfonic acid, and react at 160°C and 0.08kPa under the protection of an inert gas 4h; after the reaction is completed, add methanol to fully dissolve, add ether to precipitate the reaction product, filter,...

Embodiment 2

[0058] Prepare a CTP plate backing paper by the following method:

[0059] (1) prepare polyhydroxyl hyperbranched polymer:

[0060] (1.1) Under the protection of an inert gas, drop the dimethylacetamide solution of pyromellitic dianhydride into the dimethylacetamide solution of 2,2'-dihydroxydipropylamine, fully react until the cyclic anhydride The characteristic peaks disappeared; after the reaction, toluene was added to precipitate the reaction product, filtered, and the filter residue was rotary evaporated to obtain the product; the mass ratio of the above-mentioned pyromellitic dianhydride to 2,2'-dihydroxydipropylamine was 1:4.3;

[0061] (1.2) Mix the product obtained in step (1.1), glyceric acid, and p-toluenesulfonic acid in a mass ratio of 1:425:9.8, add p-toluenesulfonic acid, and react at 165°C and 0.05kPa under the protection of an inert gas 4.5h; After the reaction is finished, add methanol to fully dissolve, then add ether to precipitate the reaction product, fi...

Embodiment 3

[0068] Prepare a CTP plate backing paper by the following method:

[0069] (1) prepare polyhydroxyl hyperbranched polymer:

[0070] (1.1) Under the protection of an inert gas, drop the dimethylacetamide solution of pyromellitic dianhydride into the dimethylacetamide solution of 2,2'-dihydroxydipropylamine, fully react until the cyclic anhydride The characteristic peaks disappeared; after the reaction, toluene was added to precipitate the reaction product, filtered, and the filter residue was rotary evaporated to obtain the product; the mass ratio of the above-mentioned pyromellitic dianhydride to 2,2'-dihydroxydipropylamine was 1:4.6;

[0071] (1.2) Mix the product obtained in step (1.1), glyceric acid, and p-toluenesulfonic acid at a mass ratio of 1:450:11.27, add p-toluenesulfonic acid, and react at 170°C and 0.02kPa under the protection of an inert gas 5h; after the reaction is finished, methanol is added to fully dissolve, then ether is added to precipitate the reaction p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com