Foldable carrying net cage structure based on marine transportation engineering

A marine transportation and engineering technology, applied in the field of foldable load net cage structure, can solve the problems of not being able to guarantee the usability of the worn parts of the cargo, affecting the operation process time, not having the limit and setting, etc., so as to facilitate assembly and timely replacement , increase the labor force, and the effect of inflexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

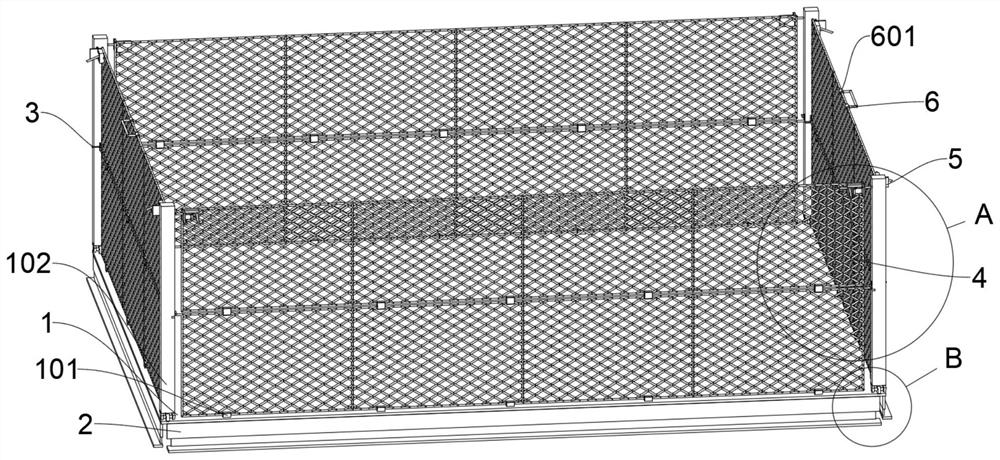

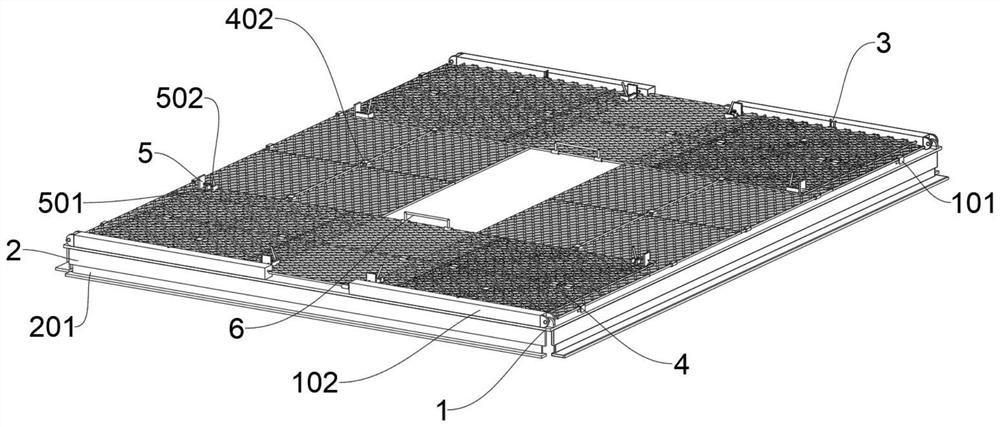

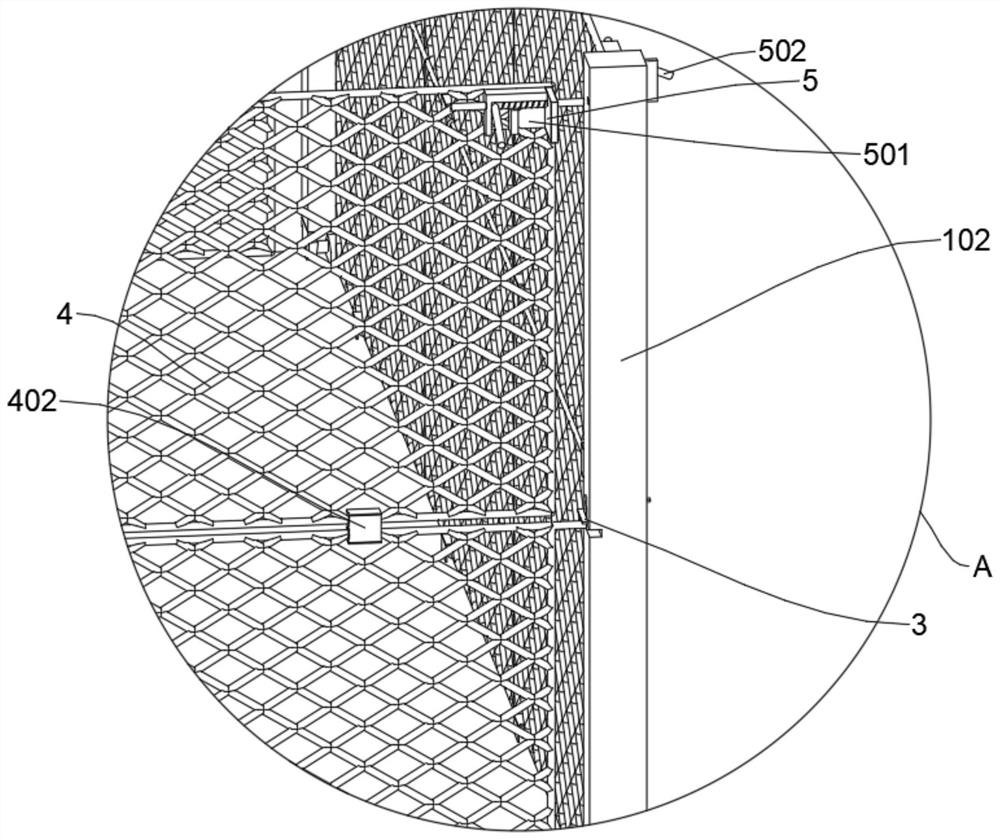

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The present invention provides a foldable net cage structure based on marine transportation engineering, including a main board 1; plate 2, and the length of the telescopic plate 2 is slightly shorter than the length of the main board 1; a groove is provided in the middle of the support rod 102, and a pressing plate 3 is fixed inside the groove; a grid plate 4 is installed on the top of the main board 1, and the grid The number of plates 4 is set to four groups; the top end of the grid plate 4 is fixedly provided with a fixed plate 5, and the number of the fixed plates 5 is set to multiple groups; two groups.

[0035]Wherein, the top surface of the main board 1 is fixedly provided with rotating shafts 101, and the number of rotating shafts 101 is set to multiple groups; font; the top of the main board 1 is fixedly provided with lugs, and the top of the lugs is rotated to set a support rod 102, and a groove is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com