Anti-crushing corrugated board

A corrugated cardboard and paper core technology, applied in the field of compressive corrugated cardboard, can solve the problems of paper core folding and low compressive strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

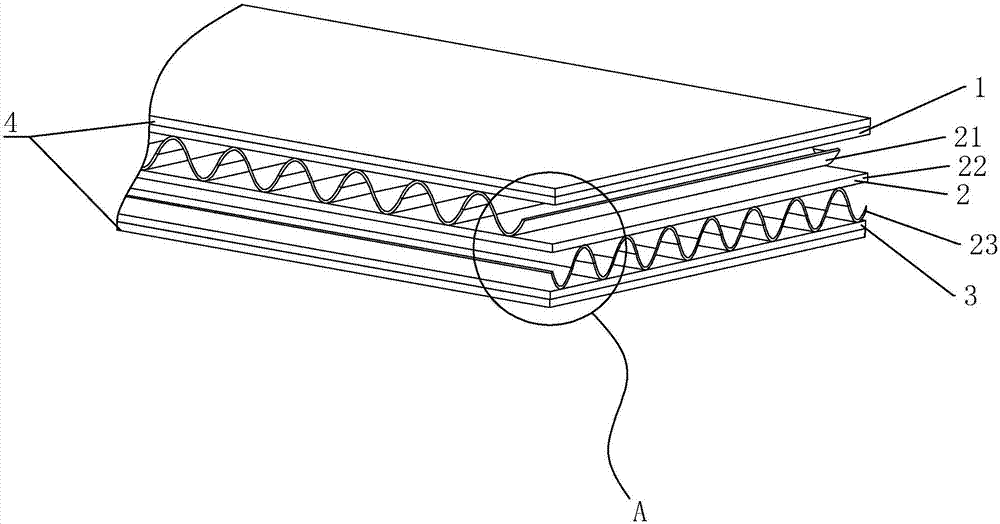

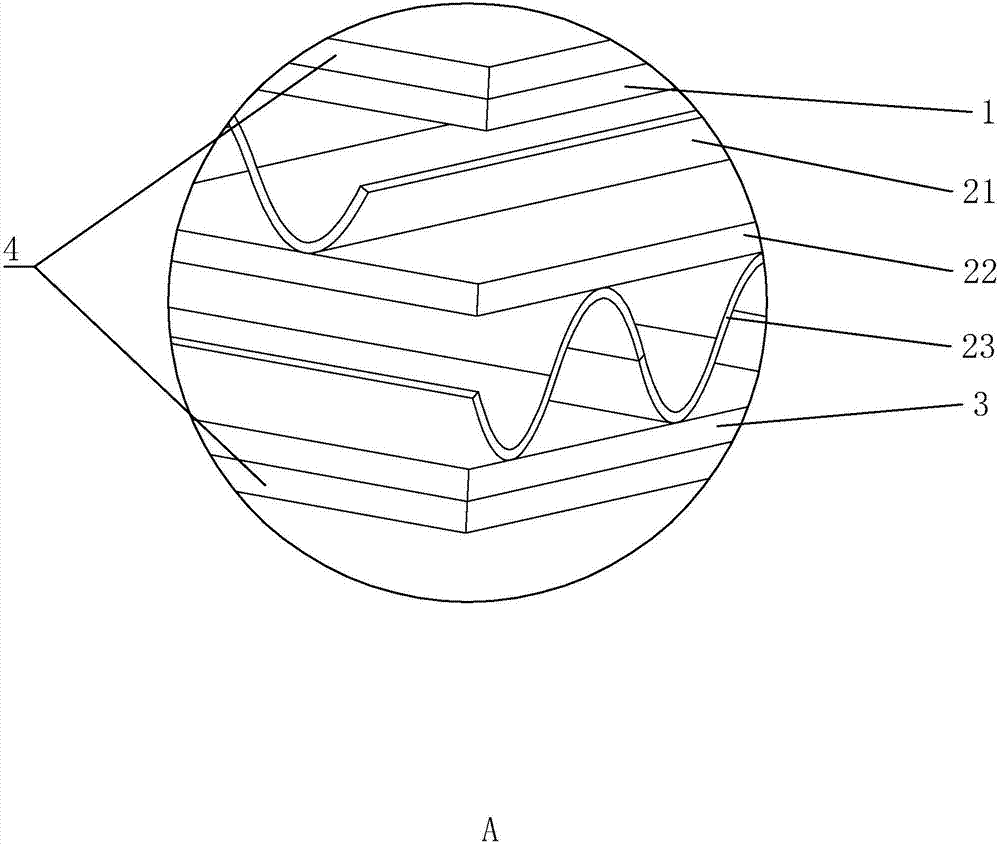

[0013] refer to Figure 1 to Figure 2 An embodiment of a compression-resistant corrugated cardboard of the present invention will be further described.

[0014] Such as figure 1 and figure 2 As shown, the main structure of this compression-resistant corrugated cardboard is the face paper 1, the paper core layer 2 and the inner paper from the outside to the inside, and the paper core layer 2 is the upper paper core layer 212, the separator 22 and the inner paper from top to bottom. The lower paper core layer 232, the upper paper core layer 212 and the lower paper core layer 232 are all arranged in a parabolic shape, and the extending direction of the upper paper core layer 212 and the extending direction of the lower paper core layer 232 are set at an angle (that is, the upper paper core layer 212 set in a different direction from the lower paper core layer 232), when the parabolic groove (or extension direction) of any layer of the upper paper core layer 212 and the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com