Automobile crankshaft thickened hub multi-wedge wheel forming technique and tool

A molding process and molding tooling technology, applied in molding tools, manufacturing tools, metal processing equipment, etc., can solve the problems of lack of positioning core, long processing time, and high consumption of materials, so as to reduce material and processing costs, and achieve stable processing. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention relates to a molding process and tooling of thickened wheel hub multi-wedge wheel of automobile crankshaft, and the specific steps are as follows:

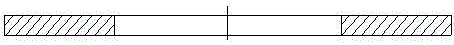

[0027] 1) Blanking punching: Punch the cut steel sheet through the special punching equipment for the center hole, such as figure 1 said;

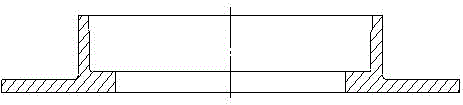

[0028] 2) Shovel forming: the steel material with the center hole punched out is rotated to create a gap from the side of the outer ring, and the surface above the gap is formed vertically, such as figure 2 said;

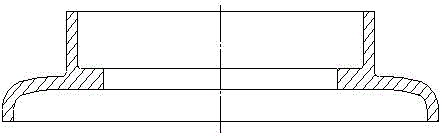

[0029] 3) Stamping and forming arc: The semi-finished product formed by shovel rotation is stamped on the surface under the gap to form an arc, such as image 3 said;

[0030] 4) Thickened helical gears: through the thickened helical gears, the arc spinning, the first preforming spinning, the second preforming wheel and the final forming spinning are respectively performed to complete the entire forming process, such as Figure 4 mentioned.

[0031] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com