Net reel for papermaking forming net inspection

A papermaking forming net and net rolling machine technology, applied in the field of net rolling machine, can solve the problems of poor control of roller line speed, undense coiling of forming net, shedding of forming net, etc., so as to reduce non-production time and achieve high dehydration performance , the effect of not easy to fold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

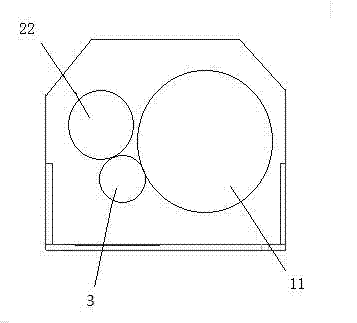

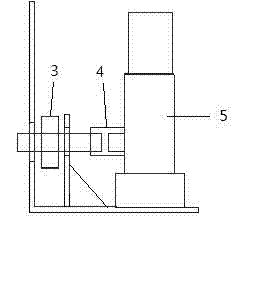

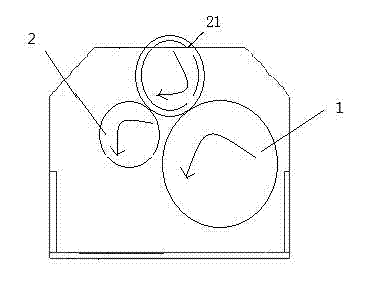

[0013] see figure 1 , figure 2 and image 3 , the present embodiment provides a paper-making forming net inspection net winding machine, including a large roll 1, a small roll 2, the large roll 1 and the small roll 2 are respectively driven by the large roll gear 11 and the small roll gear 22, the large roll gear 11 And the small roll gear 22 meshes with the driving gear 3, the driving gear 3 is driven by the web rolling motor 5, the driving gear 3 and the web rolling motor 5 are connected by the motor coupling 4, the large roll 1 and the small roll 2 are different in size, And the linear speeds of the big roll 1 and the small roll 2 are different. The linear speed of the small roll 2 is greater than that of the large roll 1. Among them, the small roller is made of seamless steel pipe with a diameter of 219 mm. The diameter ratio of big roll 1 and small roll 2 is 409 / 219, and the line speed ratio is 24720 / 24747.

[0014] The driving gear 3 and the web rolling motor 5 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com