Fabric for safety air bag

A technology of airbags and fabrics, which is applied in the direction of fabrics, vehicle safety arrangements, pedestrian/passenger safety arrangements, etc., can solve the problems of damaging the closed structure of polymer welding beads, fabric welding beads are not completely firm, and increase subsequent processes, etc., to achieve Excellent foldability, ensuring market competitiveness, and ensuring the effect of performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

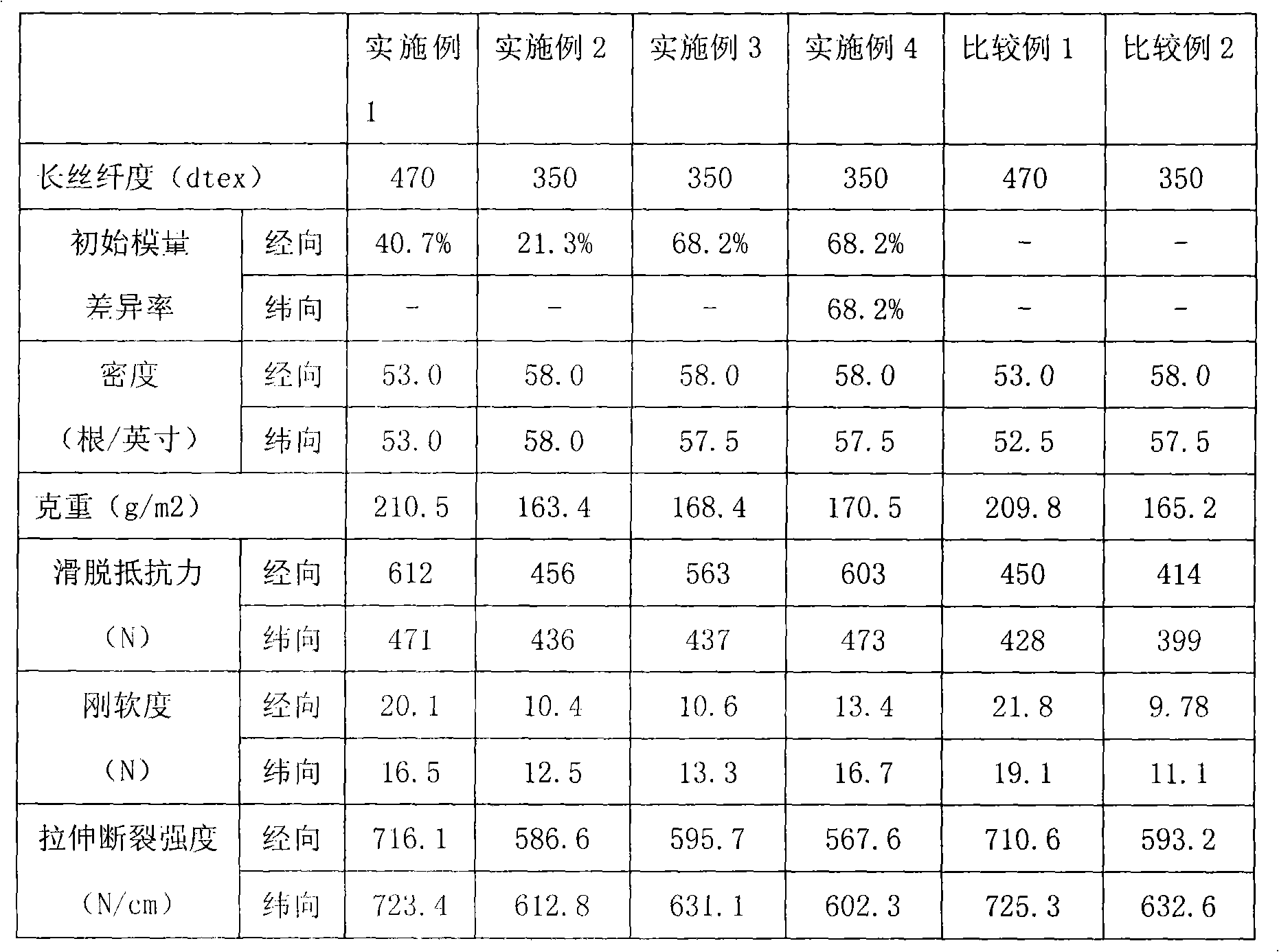

Embodiment 1

[0045] The initial modulus value is 25.8cN / dtex (the total fineness is 470dtex, the number of single filaments is 72, and the cross section is circular) and the initial modulus value is 15.3cN / dtex (the total fineness is 470dtex, the number of single filaments is 72 nylon 66 filaments with circular cross-sections have an initial modulus difference rate of 40.7%. After being warped by a warping machine, the above-mentioned two kinds of filaments are arranged evenly and spaced through parallel shafting, so that there are two kinds of filaments with different initial moduli in the warp direction, and then weaving, drying (drying temperature is 80°C), scouring, washing, Heat setting process (heat setting temperature is 180 ℃, heat setting time is 40 seconds), makes finished fabric, and the density of this finished fabric is: warp direction 53 threads / inch, weft direction 53 threads / inch. The properties of the fabric are shown in Table 1.

Embodiment 2

[0047] The initial modulus value is 25.8cN / dtex (the total fineness is 350dtex, the number of single filaments is 72, and the cross section is circular) and the initial modulus value is 20.3cN / dtex (the total fineness is 350dtex, the number of single filaments is 72 nylon 66 filaments with circular cross-sections have an initial modulus difference rate of 21.3%. After being warped by a warping machine, the above-mentioned two kinds of filaments are arranged evenly and spaced through parallel shafting, so that there are two kinds of filaments with different initial moduli in the warp direction, and then weaving, drying (drying temperature is 80°C), scouring, washing, Heat setting process (heat setting temperature is 180 ℃, heat setting time is 40 seconds), makes finished fabric, and the density of this finished fabric is: warp direction 58 threads / inch, weft direction 58 threads / inch. The properties of the fabric are shown in Table 1.

Embodiment 3

[0049] The initial modulus value is 40.3cN / dtex (the total fineness is 350dtex, the number of single filaments is 72, and the cross section is circular), and the initial modulus value is 28.5cN / dtex (the total fineness is 350dtex, and the number of single filaments is 72, the section is circular) and the initial modulus value is 12.8cN / dtex (the total fineness is 350dtex, the number of monofilaments is 72, and the section is circular) of nylon 66 filaments, the initial modulus difference is 68.2%. After being warped by a warping machine, the above-mentioned three kinds of filaments are arranged evenly at intervals through parallel shafting, so that there are three kinds of filaments with different initial moduli in the warp direction, and then weaving, drying (drying temperature is 80°C), scouring, washing, Heat setting process (heat setting temperature is 180 ℃, heat setting time is 40 seconds), makes finished fabric, and the density of this finished fabric is: warp direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial modulus | aaaaa | aaaaa |

| Initial modulus | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com