Spraying-free polycarbonate/acrylonitrile styrene/ultrahigh molecular weight polyethylene (PC/AS/UHMWPE) composite material and preparation method thereof

A composite material and spray-free technology, which is applied in the field of polymers, can solve the problems of low surface hardness, easy to scratch the product surface, and non-repeatable use, etc., and achieve the effects of not being easy to fold, excellent fluidity, and delaying aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

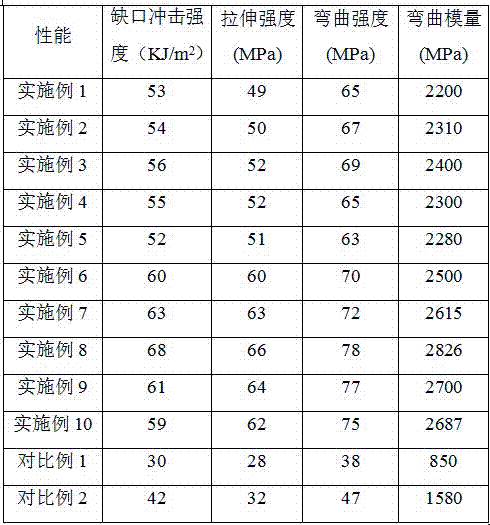

Examples

Embodiment 1

[0038] A spray-free PC / AS / UHMWPE composite material, the composite material includes the following raw materials in parts by weight:

[0039] 20 parts polycarbonate

[0040] Acrylonitrile-styrene copolymer 50 parts

[0041] UHMWPE 20 parts

[0042] Brightener 5 parts

[0043] 3 servings glass beads

[0044] Antioxidant 2 parts

[0045] Anti-UV agent 1 part

[0046] Heat stabilizer 2 parts.

[0047] The characteristic density of the polycarbonate is 1.1823-1.2186g / cm 3 , the linear expansion rate is 3.2×10 -5 cm / °C.

[0048] The relative density of the acrylonitrile-styrene copolymer is 1.0578, and the refractive index is 1.50.

[0049] The brightener is modified amide wax.

[0050] The particle size of the glass microspheres is 15 μm, and the roundness rate is 85%.

[0051] The antioxidant is 1,3,5-tris(3,5-di-tert-butyl-4-hydroxyphenyl) isocyanate.

[0052] The anti-UV agent is 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole.

[0053] The thermal st...

Embodiment 2

[0058] A spray-free PC / AS / UHMWPE composite material, the composite material includes the following raw materials in parts by weight:

[0059] 35 parts polycarbonate

[0060] Acrylonitrile-styrene copolymer 42 parts

[0061] UHMWPE 32 parts

[0062] Brightener 8 parts

[0063] 5 parts glass beads

[0064] Antioxidant 3.5 parts

[0065] Anti-UV agent 2 parts

[0066] Heat stabilizer 4 parts.

[0067] The characteristic density of the polycarbonate is 1.1913g / cm 3 , the linear expansion rate is 3.5×10 -5 cm / °C.

[0068] The relative density of the acrylonitrile-styrene copolymer is 1.0640, and the refractive index is 1.53.

[0069] The brightener is polyethylene wax.

[0070] The particle size of the glass microspheres is 42.5 μm, and the roundness rate is 88%.

[0071] The antioxidant is 4,4'-thiobis(3-methyl-6-tert-butylphenol).

[0072] The anti-UV agent is 2-hydroxyl-4-methoxybenzophenone or 2,2'-thiobis(4-tert-octylphenoxy)nickel.

[0073] The heat stabilizer is...

Embodiment 3

[0078] A spray-free PC / AS / UHMWPE composite material, the composite material includes the following raw materials in parts by weight:

[0079] Polycarbonate 50 parts

[0080] Acrylonitrile-styrene copolymer 35 parts

[0081] UHMWPE 45 parts

[0082] Brightener 10 parts

[0083] 7 servings glass beads

[0084] Antioxidant 5 servings

[0085] Anti-UV agent 3 parts

[0086] Heat stabilizer 6 parts.

[0087] The characteristic density of the polycarbonate is 1.2003g / cm 3 , the linear expansion rate is 3.8×10 -5 cm / °C.

[0088] The relative density of the acrylonitrile-styrene copolymer is 1.0702, and the refractive index is 1.58.

[0089] The brightener is RQT-G-1 type brightener.

[0090] The particle size of the glass microspheres is 70 μm, and the roundness rate is 90%.

[0091] The antioxidant is 2,6-di-tert-butyl-p-cresol or 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane.

[0092] The anti-UV agent is phenyl o-hydroxybenzoate or tris(1,2,2,6,6-pentamethylp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com