Rotary pressing tooling for manufacturing asymmetric T-shaped rotary pressing belt wheels

A pulley, asymmetric technology, applied in the direction of manufacturing tools, forming tools, metal processing equipment, etc., can solve the problems of high process requirements and difficult processing, and achieve the effect of good spinning effect, stable processing process, and difficult material folding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

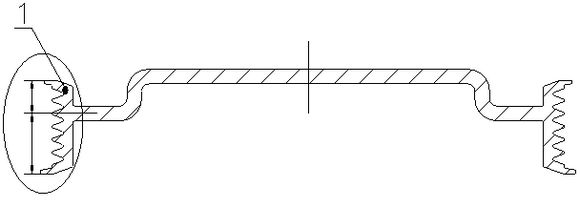

[0021] figure 1 The middle is the T-shaped pulley groove 1 (spinning pulley with T-shaped structure). The T-shaped wheel groove 1 is asymmetrical up and down relative to the center of the sheet material. The higher the asymmetric ratio, the higher the requirement for material flow control, and the more difficult it is to manufacture.

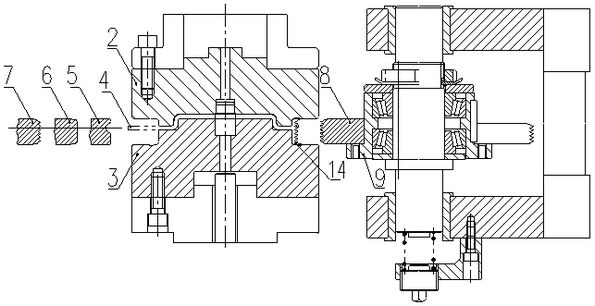

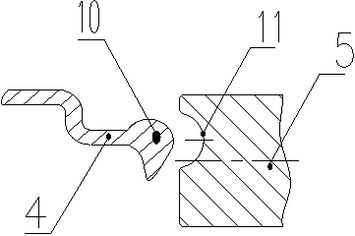

[0022] figure 2 Among them, the upper mandrel 2 and the lower mandrel 3 are installed on the central axis of the spinning equipment, which are used to clamp the sheet 4 (processing blank) and form the cavity of the product; T-shaped thickening wheel 5, flat wheel 6, The preformed toothed wheel 7 and the final formed toothed wheel 8 are respectively installed around the central axis of the spinning equipment on four symmetrically distributed wheel shafts 9 (the wheel shafts are distributed between the upper mandrel 2 and the lower mandrel 3 Around, the T-shaped thickened rotary wheel is installed on the first rotary wheel shaft; the flat rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com