Megnetoelectric changing element and its producing method

A manufacturing method and technology of magneto-sensitive elements, which are applied in the manufacture/processing of electromagnetic devices, measurement of magnetic variables, and parts of electromagnetic equipment, etc. problem, to achieve the effect of reducing the manufacturing process, simple structure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

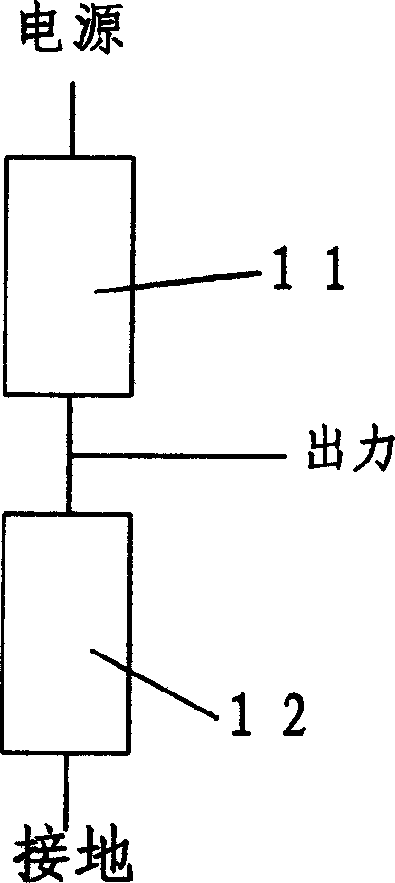

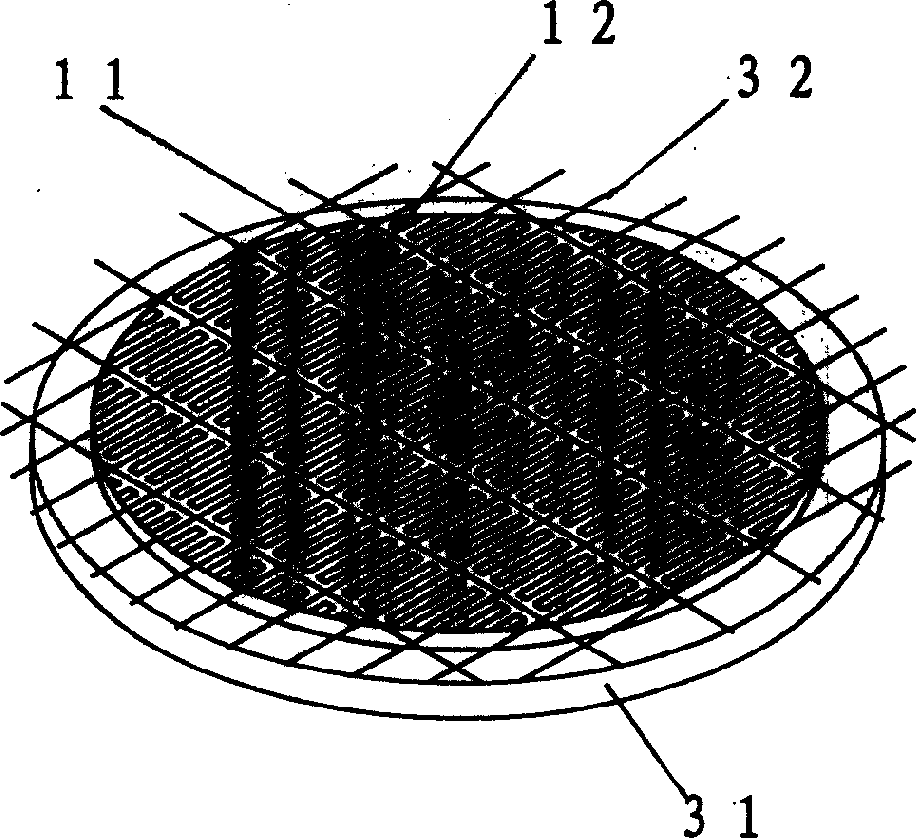

[0043] The inventive point of the present invention is that the magnetoelectric conversion element uses a small permanent magnet as the substrate supporting the magnetic sensitive element that changes with the change of the magnetic field, instead of Figure 4 , Figure 5 In the substrate 31 shown in the prior art, the small permanent magnet not only functions as a substrate, but also acts as a bias magnet.

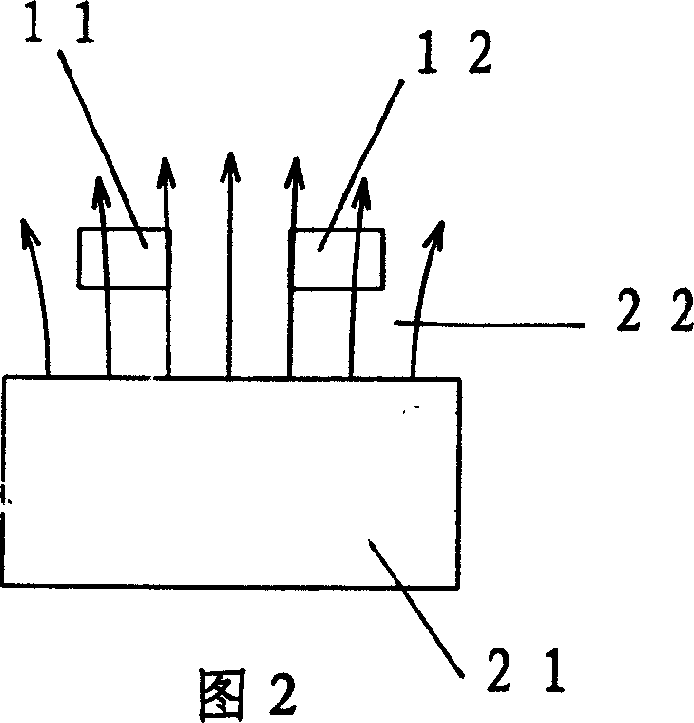

[0044] With the magnetoelectric conversion element made by the present invention, its structure and positional relationship are as follows: Figure 15 As shown, 11 and 12 are a pair of divided magnetic sensitive elements, and the magnetic sensitive elements can be made of indium antimonide material; Two pairs of divided magnetic sensitive elements 11 , 12 and permanent magnet 122 are glued and fixed on the fixing plate 51 . The fixing plate 51 and the magnetoelectric conversion element are electrically connected by a metal wire 152 . In order to leave a certain distanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com