PFTTH (power fiber to the home) cable

A technology of power optical fiber and cable, which is applied in the direction of power cables, insulated cables, cables, etc., can solve the problems of thick outer diameter, poor stripping performance, and inconvenient construction, and achieve increased communication capacity, good tearing performance, and easy construction. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

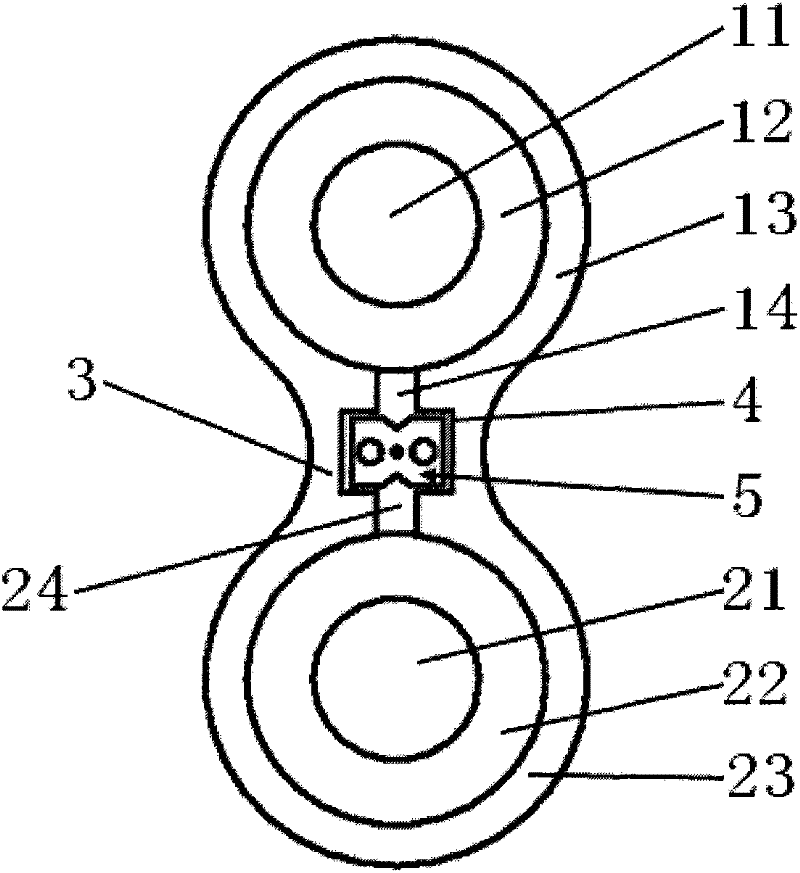

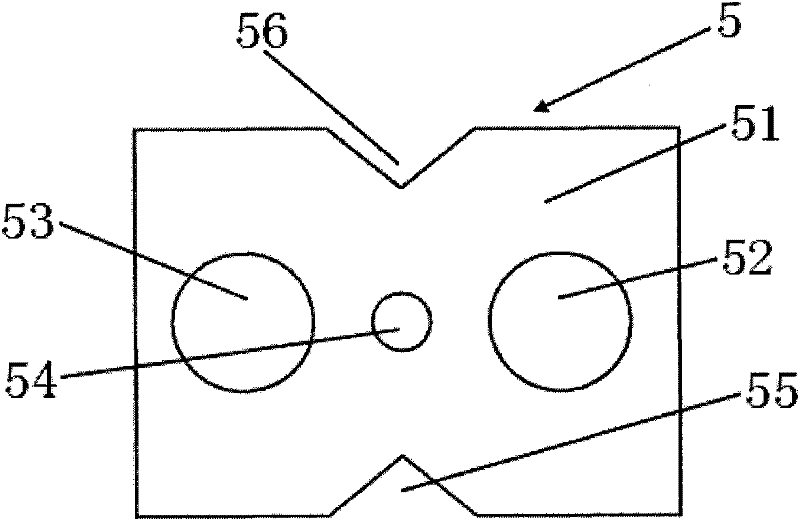

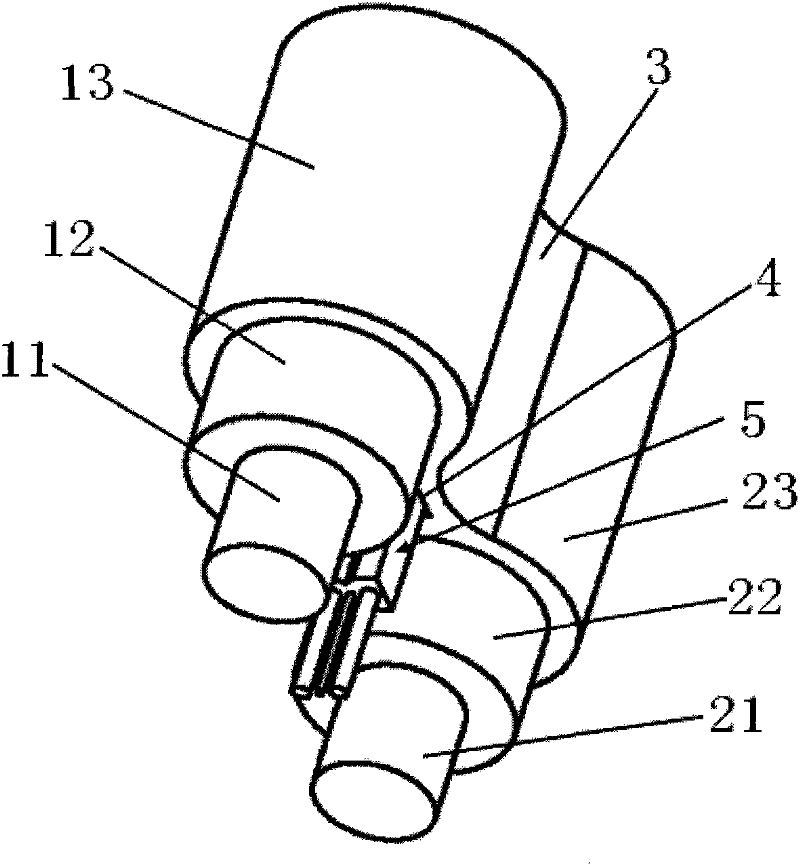

[0032] See Figure 1 to Figure 3, a power optical fiber to the home cable is characterized in that it includes: a first insulated wire made of a first conductor 11 and a first insulating layer 12 covering the first conductor, a second conductor 21 and a first insulating layer covering the first conductor The second insulated wire made of the second insulating layer 22 of the second conductor, a butterfly cable 5, the first outer sheath 13 covering the first insulated wire, the second outer sheath covering the second insulated wire Layer 23, the third outer sheath 3 covering the butterfly optical cable and the cavity 4 that is located in the third outer sheath and can accommodate the butterfly optical cable; the first insulated wire, the second insulated wire, the butterfly The cable is distributed in parallel in space, and the first insulated wire and the second insulated wire are respectively located on both sides of the butterfly cable; the first outer sheath 13, the second ...

Embodiment 2

[0034] please see Figure 4 , and refer to Figure 1 to Figure 3 , a power optical fiber to the home cable is characterized in that it includes: a first insulated wire made of a first conductor 11 and a first insulating layer 12 covering the first conductor, a second conductor 21 and a first insulating layer covering the first conductor The second insulated wire made of the second insulating layer 22 of the second conductor, a butterfly cable 5, the first outer sheath 13 covering the first insulated wire, the second outer sheath covering the second insulated wire Layer 23, the third outer sheath 3 covering the butterfly optical cable and the cavity 4 that is located in the third outer sheath and can accommodate the butterfly optical cable; the first insulated wire, the second insulated wire, the butterfly The cable is distributed in parallel in space, and the first insulated wire and the second insulated wire are respectively located on both sides of the butterfly cable; the ...

Embodiment 3

[0037] please see Figure 5 , and refer to Figure 1 to Figure 3 , a power optical fiber to the home cable, basically the same as the implementation example 1, the difference is that the third outer sheath has an external tear opening 6 facing the cavity and not penetrating into the cavity; the external tear opening and The minimum distance between the inner walls of the cavity is 0.4mm.

[0038] Of course, the power fiber-to-the-home cable in any of the above embodiments is characterized in that the third outer sheath has an external tear opening 6 facing the cavity and not penetrating into the cavity.

[0039] Certainly, the power fiber-to-the-home cable in any of the above-mentioned embodiments is characterized in that the optical fiber is a G.652 type, a G.655 type, a G.657 type, or a multimode optical fiber type.

[0040] Certainly, the power fiber-to-the-home cable in any of the above embodiments is characterized in that the first strengthening member is steel wire or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com