Packaging box manufactured by adopting light calcium silicate hollow board

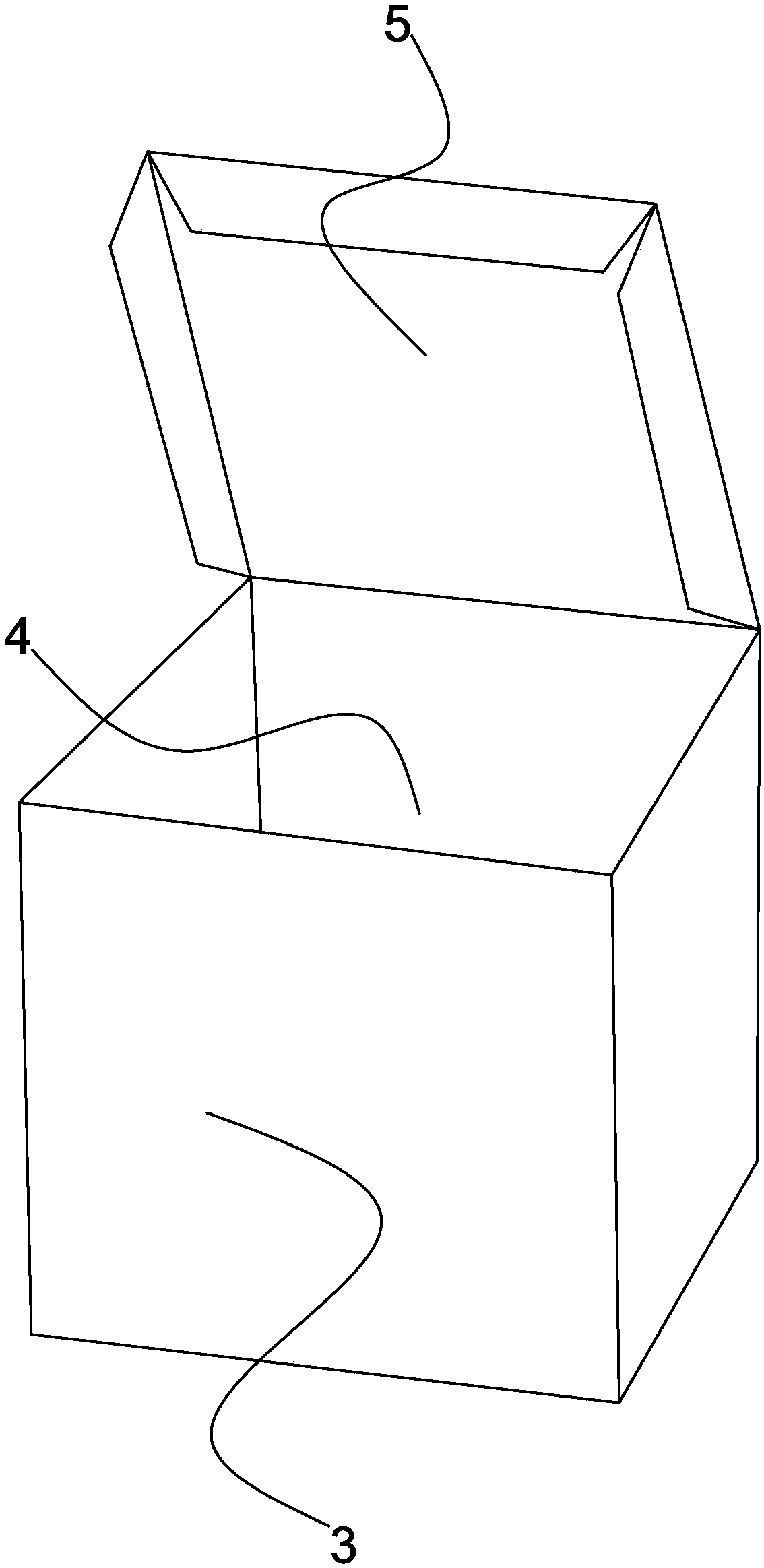

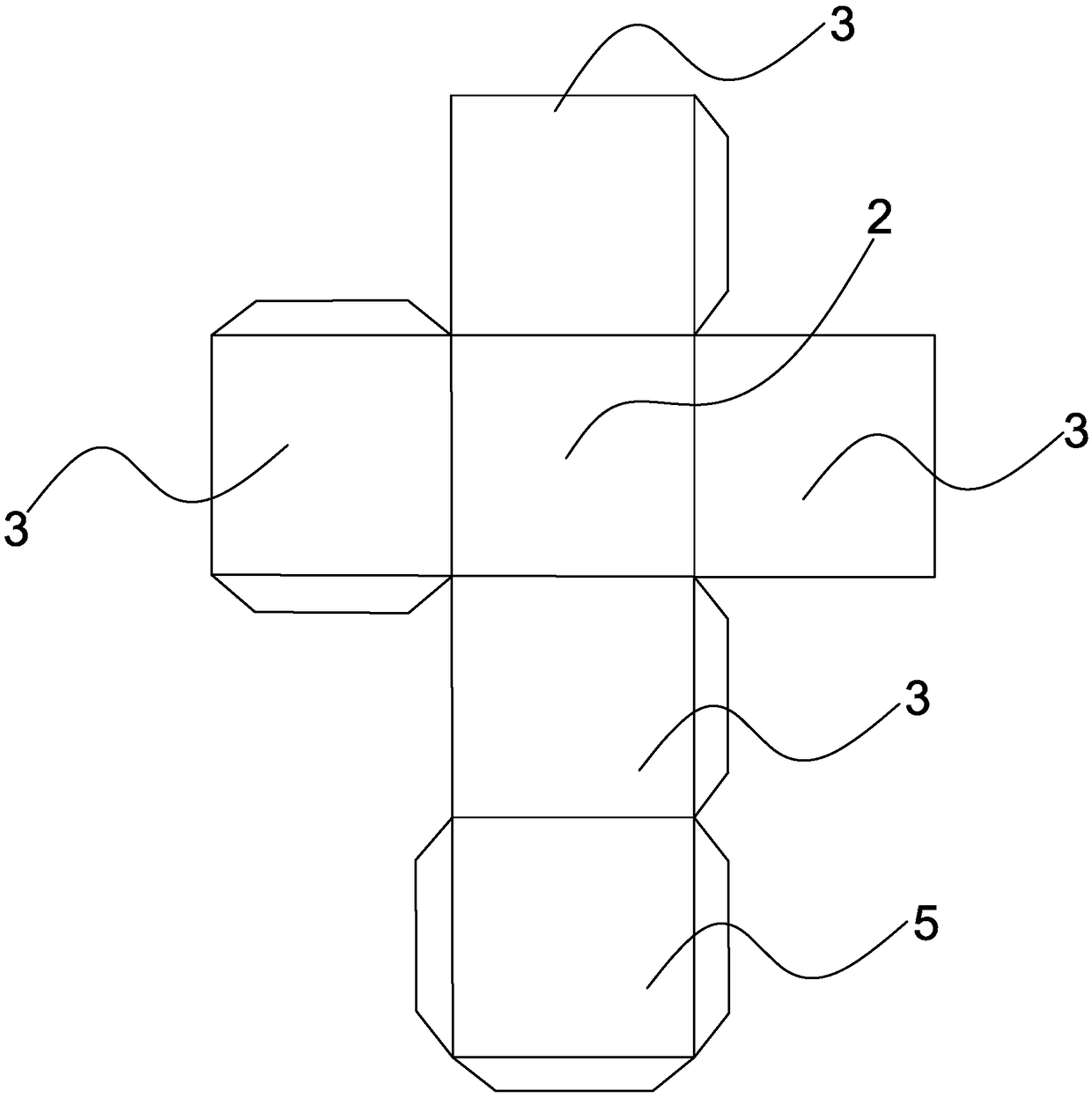

A packaging box, silicon calcium technology, applied in the field of packaging boxes, can solve the problems of poor toughness and tear resistance, easy to pollute the environment, high production cost, achieve good cushioning and shock absorption performance and bending performance, not easy to break, less consumables Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

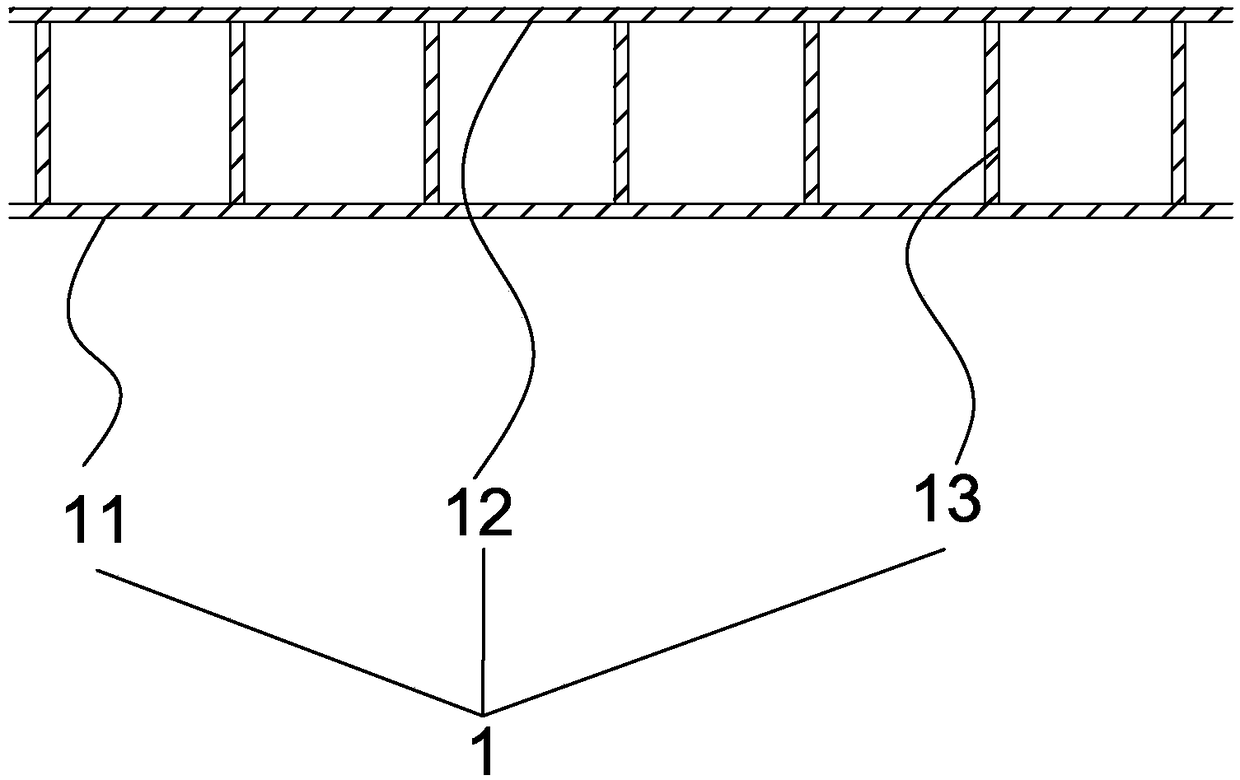

[0038] A lightweight calcium silicate hollow board 1, its material is composed of the following components by weight percentage: PP resin 65%, diatomaceous earth 23%, talcum powder 7%, toughening agent 2%, compatibilizer 7%, even Joint agent 0.3%, antioxidant 0.3%.

[0039] The preparation method of the lightweight calcium-silicon hollow board 1 of this embodiment 1 is as follows:

[0040] 1 Raw material handling and mixing

[0041] Mix the PP resin, diatomaceous earth, talcum powder and toughening agent in a mixing mixer for 3 minutes, stir well to disperse the components evenly, and the temperature is 100°C; then add compatibilizer, coupling agent and anti-corrosion agent The oxygen agent was mixed and stirred for 5 minutes to obtain a mixture;

[0042] 2 melt extrusion

[0043] Put the mixture into a twin-screw extruder to heat, melt, extrude and plasticize to obtain a semi-finished product. The working conditions are: the temperature is 200°C, and the screw speed is 400...

Embodiment 2

[0047] The preparation method of the lightweight calcium-silicon hollow board 1 of this embodiment 2 is as follows:

[0048]A lightweight calcium silicate hollow board 1, its material is composed of the following components by weight percentage: PP resin 66%, diatomaceous earth 25%, talcum powder 6%, toughening agent 1%, compatibilizer 6%, even Joint agent 0.4%, antioxidant 0.3%.

[0049] 1 Raw material handling and mixing

[0050] Mix the PP resin, diatomaceous earth, talcum powder and toughening agent in a mixing mixer for 5 minutes, stir well to disperse the components evenly, and the temperature is 90°C; then add compatibilizer, coupling agent and anti-corrosion agent The oxygen agent was mixed and stirred for 8 minutes to obtain a mixture;

[0051] 2 melt extrusion

[0052] Put the mixture into a twin-screw extruder to heat, melt, extrude and plasticize to obtain a semi-finished product. The working conditions are as follows: the temperature is 195°C, and the screw spe...

Embodiment 3

[0056] The preparation method of the lightweight calcium-silicon hollow board 1 of this embodiment 3 is as follows:

[0057] A lightweight calcium silicate hollow board 1, its material is composed of the following components by weight percentage: PP resin 68%, diatomaceous earth 24%, talcum powder 6%, toughening agent 3%, compatibilizer 6%, even Joint agent 0.4%, antioxidant 0.4%.

[0058] 1 Raw material handling and mixing

[0059] Mix the PP resin, diatomaceous earth, talcum powder and toughening agent in a mixing mixer for 3 minutes, fully stir to disperse the components evenly, and the temperature is 80°C; then add compatibilizer, coupling agent and anti-corrosion agent The oxygen agent was mixed and stirred for 6 minutes to obtain a mixture;

[0060] 2 melt extrusion

[0061] Put the mixture into a twin-screw extruder to heat, melt, extrude and plasticize to obtain a semi-finished product. The working conditions are as follows: the temperature is 205°C, and the screw s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com