Easy-tearing, anti-fake, and ultrahigh frequency paper-base RFID label and manufacturing method thereof

A technology of RFID tags and manufacturing methods, which is applied to record carriers, instruments, computer parts, etc. used in machines, can solve the problems of high manufacturing cost, high rejection rate, unstable performance, etc., and achieves improved process stability and low cost. , the effect of high qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

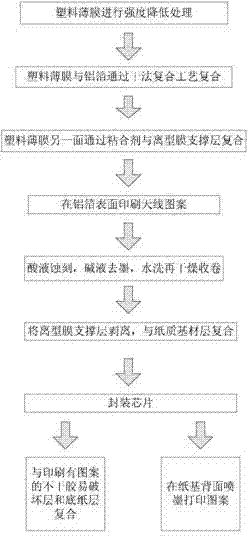

[0044] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through preferred embodiments.

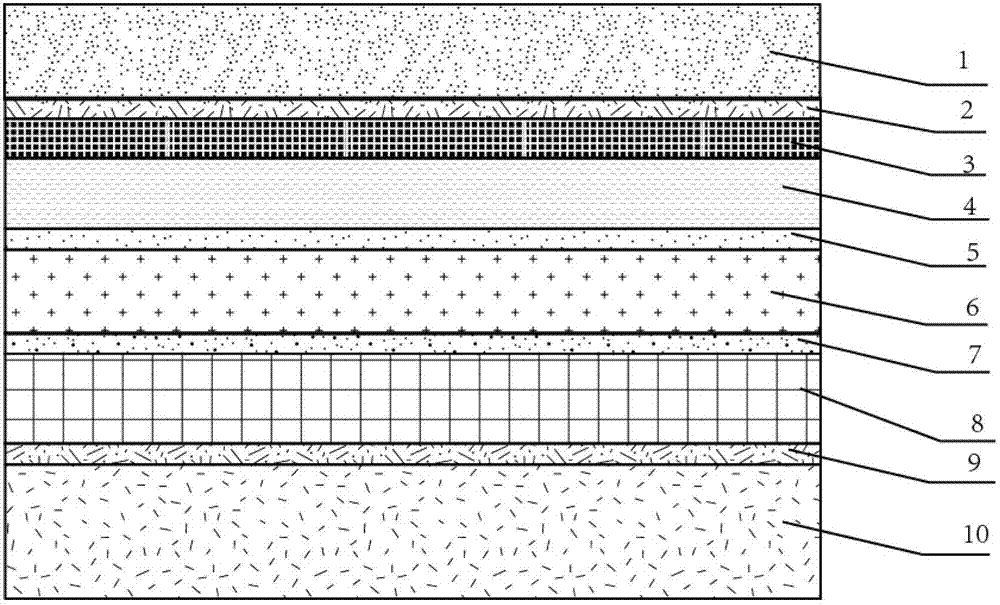

[0045] see figure 1 As shown, the paper-based easy-tear anti-counterfeiting ultra-high frequency RFID tag in this embodiment, the easy-to-break layer 1, the first self-adhesive layer 2, the electronic chip layer 3, the antenna circuit layer 4, the dry composite process adhesive layer 5, The film base layer 6, the adhesive layer 7, the paper base support layer 8, the second self-adhesive layer 9, the bottom paper layer 10, the inner surface of the fragile layer 1 is bonded to the electronic chip through the first self-adhesive layer 2 One side of the layer 3, the other side of the electronic chip layer 3 is compounded with one side of the antenna circuit layer 4, and the other side of the antenna circuit layer 4 is bonded to one side of the film base material layer 6 through the dry lamination process adhesive layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com