Polyethylene composite film and preparation method thereof

A composite film and polyethylene technology, which is applied in chemical instruments and methods, flat products, and other household appliances, etc., can solve problems such as poor compatibility, limited use of PE film, and weak antibacterial properties of antibacterial agents, and achieve high compatibility, Effect of improving tearability and enhancing straight-line tearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The raw materials for the preparation of the outer layer include the first low-density polyethylene and high-density polyethylene;

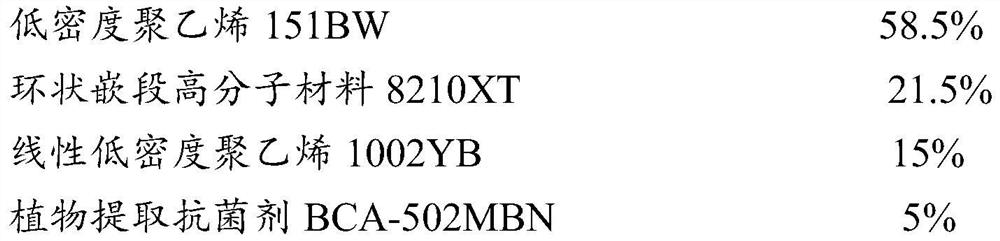

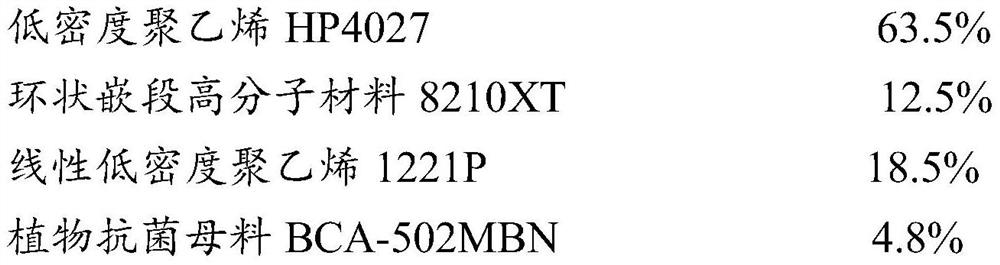

[0024] The raw materials for the preparation of the middle layer include second low-density polyethylene, cyclic block polymer material, plant antibacterial masterbatch and linear low-density polyethylene;

[0025] The raw materials for preparing the inner layer include the first low-density polyethylene, metallocene low-density polyethylene and plant antibacterial masterbatch.

[0026] In the present invention, unless otherwise specified, the raw materials used in the present invention are preferably commercially available products.

[0027] In terms of the mass percentage of the outer layer, the raw material for the preparation of the outer layer in the present invention preferably includes 50-90% by mass of the first low-density polyethylene, more preferably 60-85%. In the present invention, the melt index of the first low-density poly...

Embodiment 1

[0070] In the polyethylene composite film prepared in this example, the mass ratio of the outer layer, middle layer and inner layer is 30:40:30;

[0071] In terms of mass percentage, the preparation raw materials of the outer layer are:

[0072] Low Density Polyethylene LB7500N 82%

[0073] Density Polyethylene C828A 18%

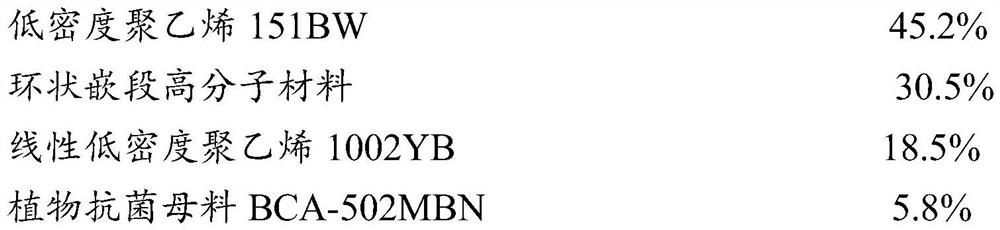

[0074] In terms of mass percentage, the preparation raw materials of the middle layer are:

[0075]

[0076] In terms of mass percentage, the preparation raw materials of the inner layer are:

[0077] Low Density Polyethylene LB7500N 75.5%

[0078] Metallocene Low Density Polyethylene 3518PA 20%

[0079] Plant antibacterial masterbatch BCA-502MBN 4.5%

[0080] The preparation method is:

[0081] The raw materials of the outer layer, the middle layer and the inner layer are respectively dosed in proportion by the automatic batching system, and then sent to the feed ports of the outer layer, middle layer and inner layer of the extruder respectively, a...

Embodiment 2

[0086] The difference between this embodiment and Embodiment 1 is that the mass ratio of the outer layer, middle layer and inner layer is 25:45:30, and other operations and parameters remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com