Flexible packaging modified CPP (Chlorinated Polypropylene) thin film and production method thereof

A flexible packaging and modification technology, which is applied in the field of flexible packaging modified CPP film, can solve the problems of content deformation, affecting the final customer's purchase desire of the product, etc., and achieve the effect of improving the heat sealing strength, improving the appearance, and promising application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

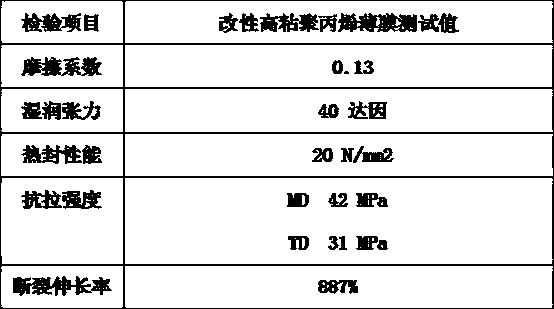

Image

Examples

Embodiment 1

[0021] Example 1 Preparation of Modified CPP Film for Flexible Packaging

[0022] ①Corona outer layer raw material A: Mix homopolymer PP (Dushanzi 830) and copolymer PP (Dushanzi 725) to form raw material A. Wherein, the weight percentage of homopolymerized PP is 20-40%, and the weight percentage of copolymerized PP is 60-80%.

[0023] ② Adhesive intermediate layer raw material B: take copolymerized PP (Dushanzi 725) and metallocene (Exxon 3518) and mix it into raw material B. Among them, the weight percentage of copolymerized PP is 70%, and the weight percentage of metallocene is 30%.

[0024] ③Heat-sealing inner layer raw material C: Mix bimodal PE (Mitsui SP0540), copolymerized PP (Korean Samsung TF400) and opening slip agent to form raw material C. Among them, bimodal PE weight percentage: copolymerized PP weight percentage is 25%,: 75%, and the weight of opening smooth agent is 2% of the sum of bimodal PE and copolymerized PP weight.

[0025] ④ Feed corona outer layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com