Three-layer co-extrusion ultra-low temperature heat-sealing package thin film

A low-temperature heat-sealing and three-layer co-extrusion technology, applied in packaging, wrapping paper, household packaging, etc., can solve the problems of low friction coefficient, high composite fastness, and difficult to reduce, and achieve good softness, improved quality, Increased effect of heat-sealed windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

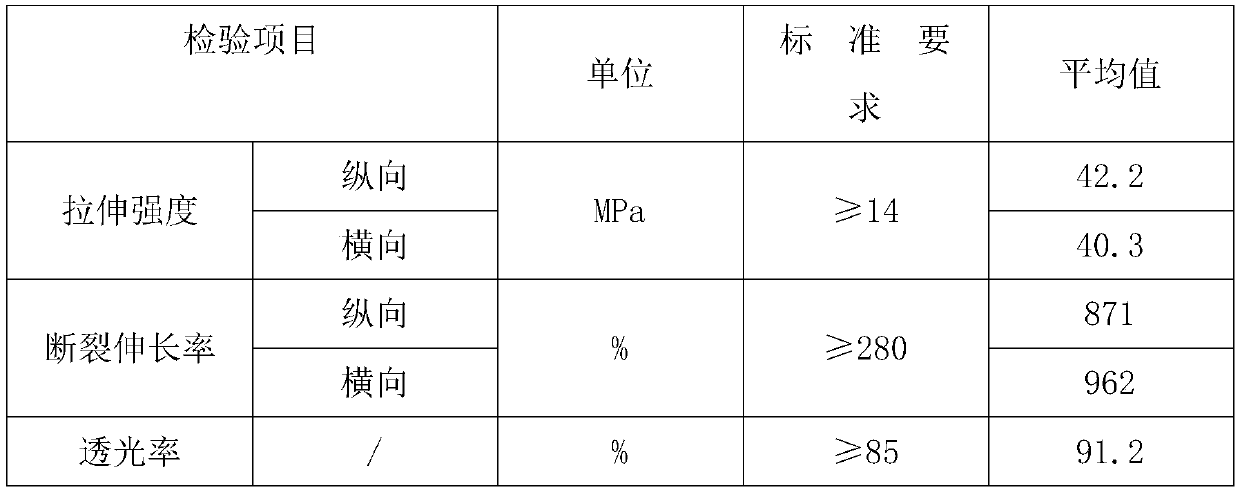

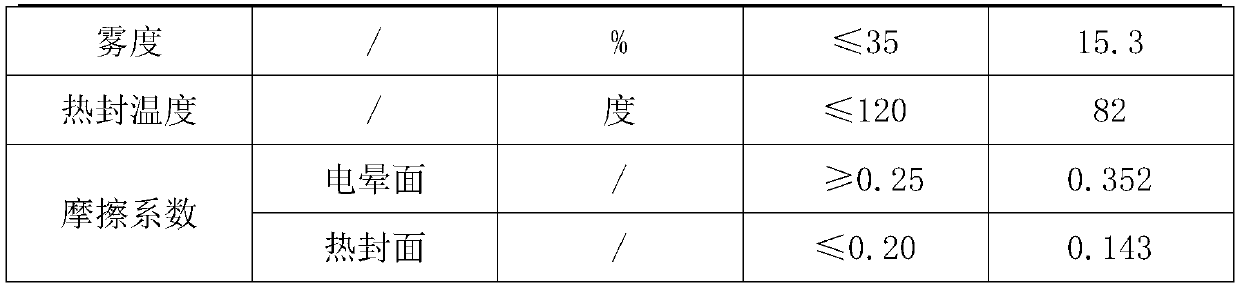

Embodiment 1

[0031] Raw material formula of the present invention is as follows: each component is by weight percentage,

[0032] inner layer:

[0033] Yamba linear polyethylene material 20%, metallocene linear material imported from Japan 55%, low density polyethylene material 19.5%, opening smooth agent: 2.5%, PPA masterbatch 3%.

[0034] Middle:

[0035] 38% metallocene linear material imported from Japan, 15% low-density polyethylene material, 44.5% domestic linear polyethylene material, and 2.5% PPA masterbatch.

[0036] Outer layer:

[0037] Yamba linear polyethylene material is 54%, metallocene linear material imported from the United States is 25%, low-density polyethylene material is 18%, and PPA masterbatch is 3%.

[0038] The Yamba linear polyethylene material is Yamba 7050H, the metallocene linear material imported from Japan is Japan KF360T, the low-density polyethylene material is China Shipping Shell 2420D, the domestic linear polyethylene is Lanzhou Petrochemical 7042, a...

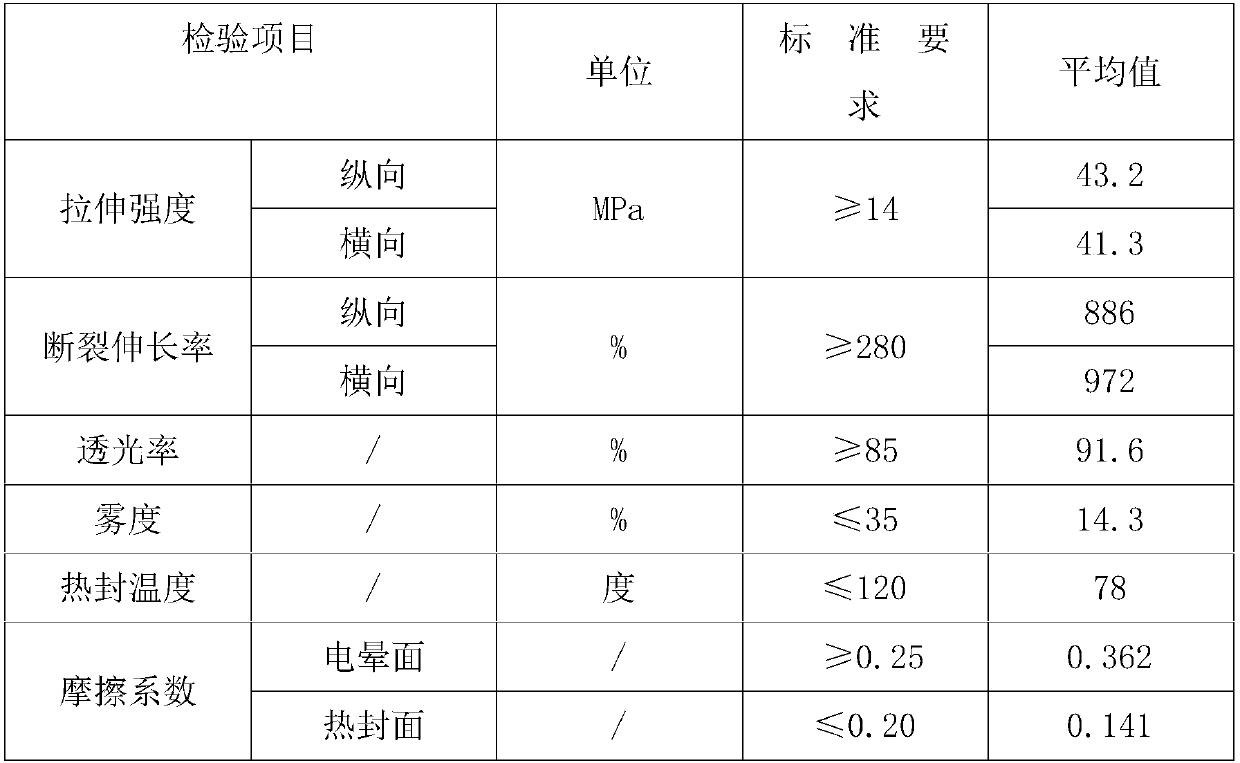

Embodiment 2

[0041] Raw material formula of the present invention is as follows: each component is by weight percentage,

[0042] 15% Yamba linear polyethylene material, 65% metallocene linear material imported from Japan, 15% low-density polyethylene material, 2% opening smoothing agent, 3% PPA masterbatch.

[0043] Middle:

[0044] 38% metallocene linear material imported from Japan, 20% low-density polyethylene material, 40% domestic linear polyethylene material, and 2% PPA masterbatch.

[0045] Outer layer:

[0046] Yamba linear polyethylene material is 45%, metallocene linear material imported from the United States is 30%, low-density polyethylene material is 22%, and PPA masterbatch is 3%.

[0047] The Yamba linear polyethylene material is Yamba 7050H, the metallocene linear material imported from Japan is Japan KF360T, the low-density polyethylene material is China Shipping Shell 2420D, the domestic linear polyethylene is Lanzhou Petrochemical 7042, and the metallocene linear pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com