Lithium ion battery plastic-aluminum membrane heat-sealing technology

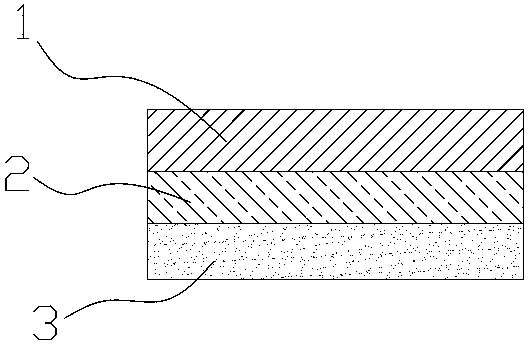

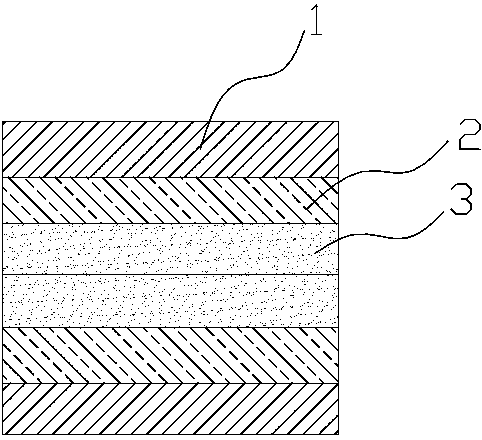

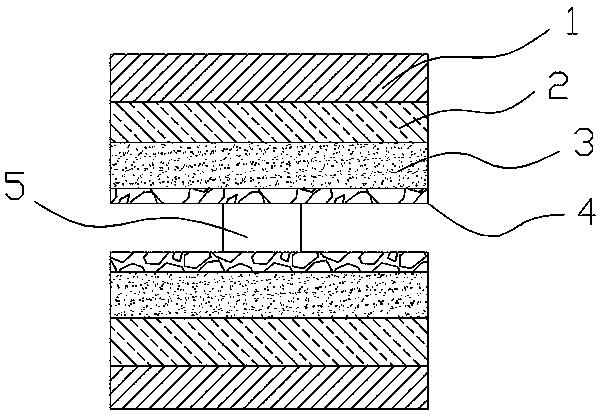

A lithium-ion battery and aluminum-plastic film technology, which is used in battery pack parts, non-aqueous electrolyte batteries, and electrolyte battery manufacturing, etc., can solve the problems of easy wrinkles, poor flatness, and inconsistent heat-sealing strength in the edge sealing of aluminum-plastic films. , to achieve the effect of good heat sealing strength, smooth surface and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A lithium-ion battery aluminum-plastic film heat-sealing process, comprising top sealing and side sealing the aluminum-plastic film, wherein the top sealing of the aluminum-plastic film includes the following steps:

[0037] (1) One-time top sealing: Based on the determined optimal top sealing process parameters, the heat sealing pressure is reduced by 30% (0.245Mpa) on the basis of the optimal top sealing pressure, and the heat sealing temperature is based on the optimal top sealing temperature 12% (224°C), the heat sealing time is reduced by 40% (1.8S) on the basis of the optimal top sealing time, and the first top sealing is performed on the aluminum-plastic film of the lithium-ion battery, that is, a top sealing is completed.

[0038] (2) Secondary top sealing: Based on the determined optimal top sealing process parameters, the heat sealing pressure is increased by 20% (0.42 Mpa) on the basis of the optimal top sealing pressure, and the heat sealing temperature is at...

Embodiment 2

[0044] A lithium-ion battery aluminum-plastic film heat-sealing process, comprising top sealing and side sealing the aluminum-plastic film, wherein the top sealing of the aluminum-plastic film includes the following steps:

[0045] (1) Primary top sealing: Based on the determined optimal top sealing process parameters, the heat sealing pressure is reduced by 45% (0.1925MPa) on the basis of the optimal top sealing pressure, and the heat sealing temperature is based on the optimal top sealing temperature The temperature is increased by 5% (210°C), and the heat-sealing time is reduced by 20% (2.4S) on the basis of the optimal top-sealing time, and the first top-sealing is performed on the aluminum-plastic film of the lithium-ion battery, that is, a top-sealing is completed.

[0046] (2) Secondary top sealing: Based on the determined optimal top sealing process parameters, the heat sealing pressure is increased by 40% (0.49MPa) on the basis of the optimal top sealing pressure, and ...

Embodiment 3

[0052] A lithium-ion battery aluminum-plastic film heat-sealing process, comprising top sealing and side sealing the aluminum-plastic film, wherein the top sealing of the aluminum-plastic film includes the following steps:

[0053] (1) Primary top sealing: Based on the determined optimal top sealing process parameters, the heat sealing pressure is reduced by 33% (0.2345MPa) on the basis of the optimal top sealing pressure, and the heat sealing temperature is based on the optimal top sealing temperature The temperature is increased by 7% (214°C), and the heat-sealing time is reduced by 23% (2.31S) on the basis of the optimal top-sealing time. The first top-sealing is performed on the aluminum-plastic film of the lithium-ion battery, that is, a top-sealing is completed.

[0054] (2) Secondary top sealing: Based on the determined optimal top sealing process parameters, the heat sealing pressure is increased by 24% (0.434MPa) on the basis of the optimal top sealing pressure, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com