Aqueous joint seal structure

A technology of sealing structure and water joint, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of large sealing friction resistance torque, short life of sealing ring, low sealing pressure resistance, etc., and achieve the increase of sealing pressure resistance , the effect of reducing frictional power consumption and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in conjunction with accompanying drawing:

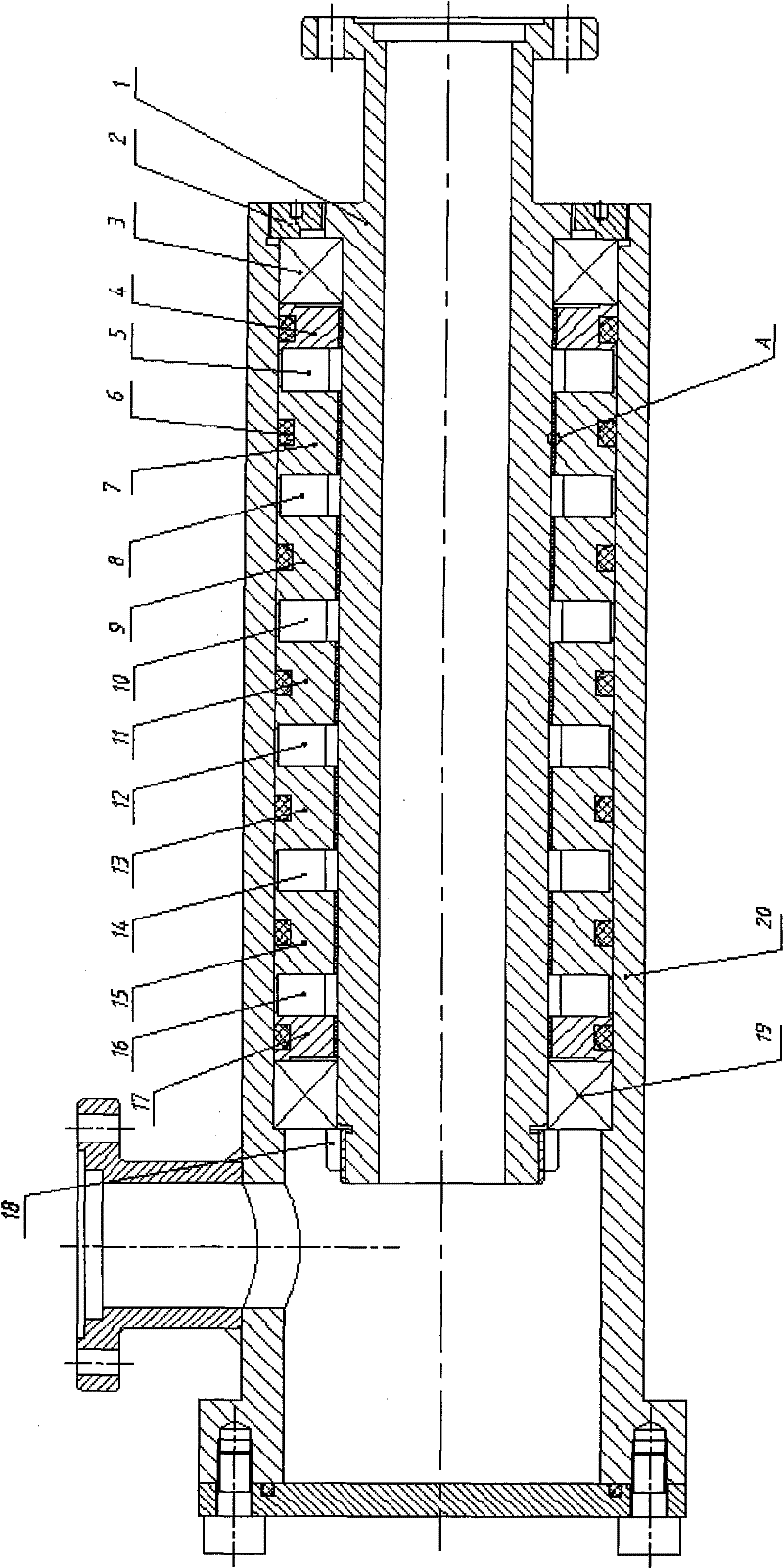

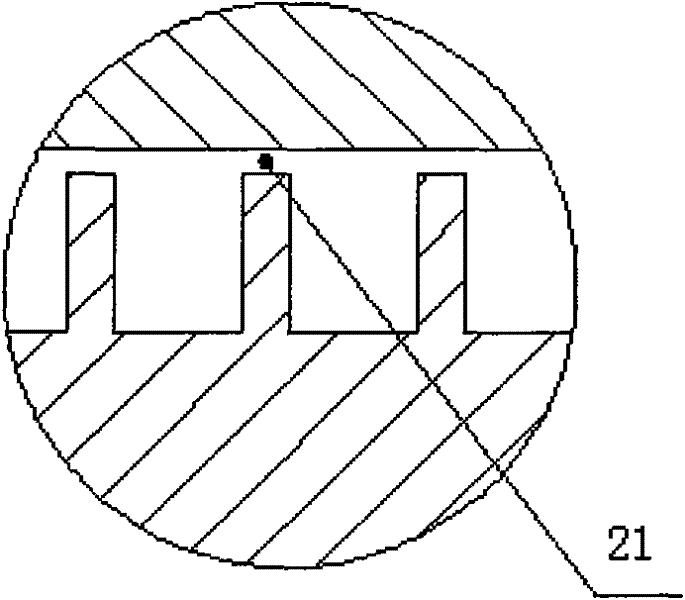

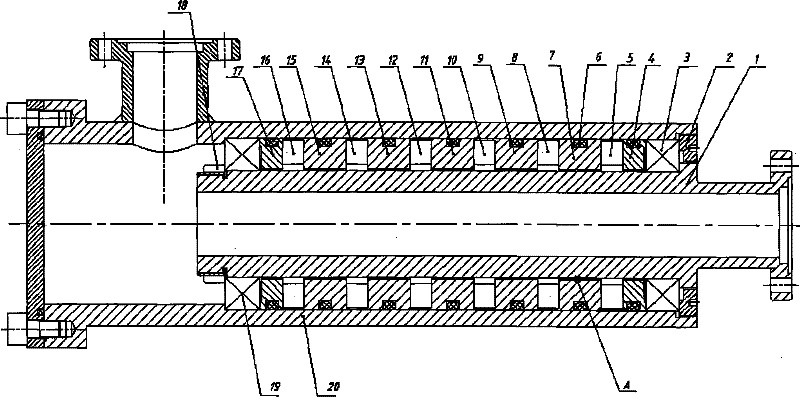

[0018] A water joint sealing structure, such as figure 1 , which consists of a hollow shaft and seal assembly supported in two bearings mounted within a housing. The sealing assembly consists of a right small pole piece 4, a first magnet 5, a first large pole piece 7, a second magnet 8, a second large pole piece 9, a third magnet 10, a third large pole piece 11, and a fourth magnet 12. , the fourth large pole piece 13, the fifth magnet 14, the fifth large pole piece 15, the sixth magnet 16, and the left small pole piece 17 are bonded in sequence;

[0019] After injecting magnetic liquid into the inner holes of the first magnet 5, the second magnet 8, the third magnet 10, the fourth magnet 12, the fifth magnet 14 and the sixth magnet 16, install the sealing assembly on the left bearing 3 and the right bearing 19 between;

[0020] The sealing assembly is fixed on the hollow shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com