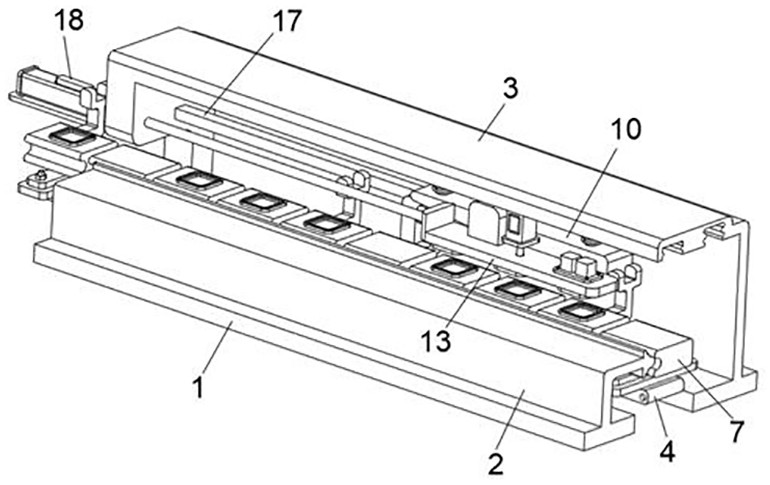

High-speed four-edge sealing reciprocating tracking heat sealing mechanism

A technology of four-side sealing and reset mechanism, which is used in packaging sealing/fastening, external support, transportation packaging, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

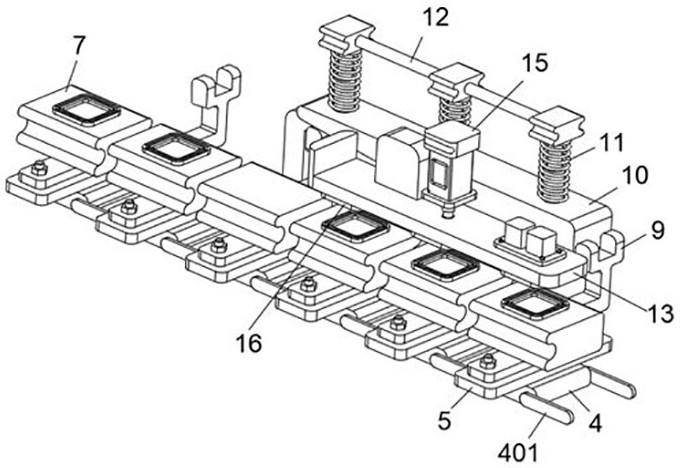

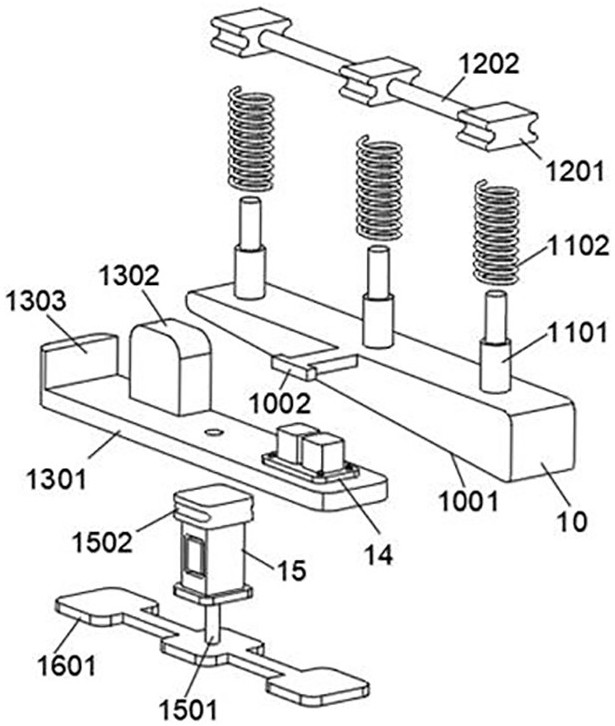

[0026] Embodiment: High-speed four-sided sealing reciprocating tracking heat-sealing mechanism, the high-speed four-sided sealing reciprocating tracking heat-sealing mechanism is composed of a conveying part, a reciprocating part and a heat-sealing part synchronized with the reciprocating part. Specifically, the conveying part adopts the existing technology Conveyor belt technology, and as a specific implementation, the existing conveyor belt is carefully divided, the conveyor belt in the prior art is changed to a plurality of conveyor blocks 4 connected, and the set of conveyor blocks 4 Through the connecting plate 401 to carry out rotational connection, under the drive of the driving motor, the conveying part provided can be driven to carry out normal conveying, and each conveying block 4 is fixedly provided with a heat-sealing plate A8, and in the actual conveying process , the film to be heat-sealed is placed on each heat-sealing plate A8, and then when the device is in ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com