Low-temperature heat-sealing non-paper packaging film for cigarettes in carton and manufacturing method thereof

A low-temperature heat-sealing and outer packaging film technology, which is applied to chemical instruments and methods, packaging, wrapping paper, etc., can solve the problems of damaging the film finish, increasing energy consumption, excessive shrinkage and melting of the film, and improving the quality of the outer packaging. Saving packaging energy consumption, excellent smoothness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

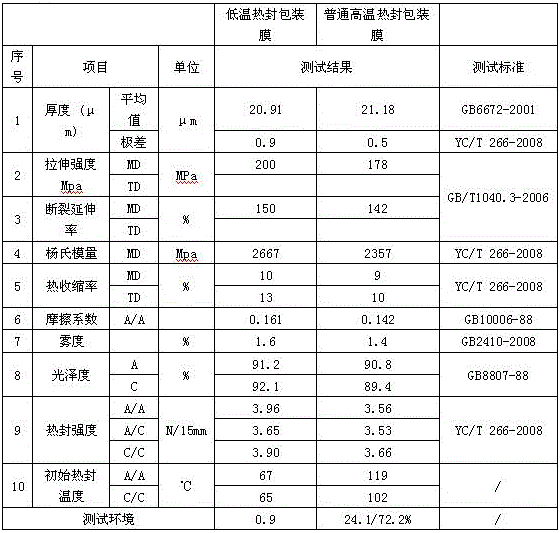

[0045] The low-temperature heat-sealing packaging film in this embodiment is obtained by co-extrusion of the surface layer A, the core layer B and the surface layer C. The total thickness of the packaging film is 20.9 μm, the thickness of the surface layer A is 0.55 μm, and the thickness of the surface layer C is 0.6 μm. The remainder is the thickness of the core layer B.

[0046] The surface layer A is made of the following components by mass:

[0047] 70 parts of ethylene-butene-propylene terpolymer,

[0048] 10 parts of ethylene-butene copolymer elastomer,

[0049] 16 parts of lubricant,

[0050] 5 parts of anti-sticking agent,

[0051] 1 part of anti-wear agent,

[0052] Among them, the slip agent is composed of 3 parts of erucamide and 13 parts of dimethicone; the anti-sticking agent is composed of 4 parts of PMMA and 1 part of silicon dioxide powder.

[0053] The core layer B is made of the following components by mass:

[0054] 80 parts of homopolypropylene,

[0...

Embodiment 2

[0067] The low-temperature heat-sealing packaging film in this embodiment is obtained by co-extrusion of the surface layer A, the core layer B and the surface layer C. The total thickness of the packaging film is 20.9 μm, the thickness of the surface layer A is 0.5 μm, and the thickness of the surface layer C is 0.8 μm. The remainder is the thickness of the core layer B.

[0068] The surface layer A is made of the following components by mass:

[0069] 80 parts of ethylene-butene-propylene terpolymer,

[0070] 8 parts of ethylene-butene copolymer elastomer,

[0071] 12 parts of lubricant,

[0072] 10 parts of anti-sticking agent,

[0073] 1 part of anti-wear agent,

[0074] Among them, the slip agent is composed of 3 parts of erucamide and 9 parts of dimethicone; the anti-sticking agent is composed of 7 parts of PMMA and 3 parts of silicon dioxide powder.

[0075] The core layer B is made of the following components by mass:

[0076] 70 parts of homopolypropylene,

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com