Water-resistant and anti-flatulence aluminum-plastic film for packaging lithium battery and preparation method of water-resistant and anti-flatulence aluminum-plastic film

A packaging and anti-flatulence technology, applied in the field of aluminum-plastic composite film, can solve the problems of poor barrier performance, poor tear strength, and affecting the safety and life of lithium-ion batteries, and achieve the effect of improving oxygen and water resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail

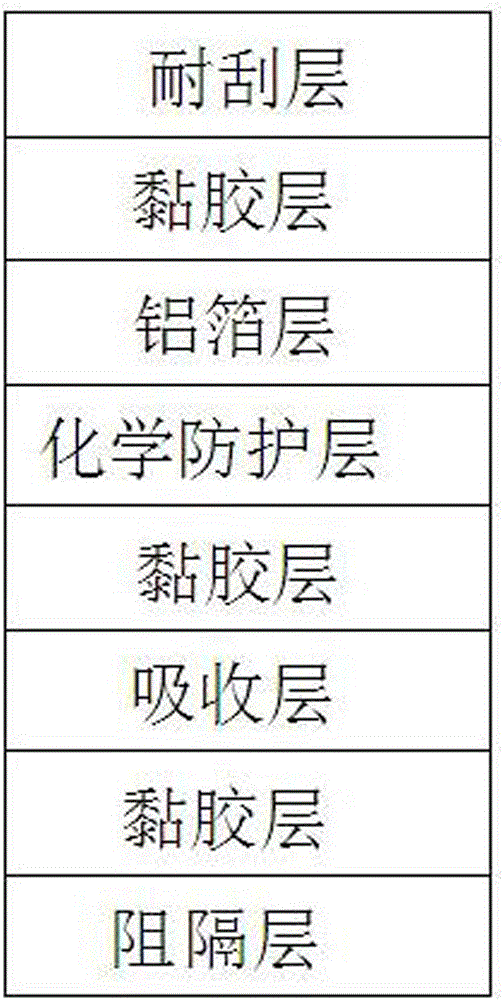

[0059] like figure 1 As shown, the water-resistant and anti-flatulence aluminum-plastic film for lithium battery packaging of the present invention has a scratch-resistant layer, an aluminum foil layer, a chemical protection layer, an absorption layer, and a barrier layer from the outside to the inside. Between the scratch-resistant layer and the aluminum foil layer, the chemical protection There are adhesive layers between the layer and the absorbing layer and between the absorbing layer and the barrier layer, and the aluminum foil layer and the chemical protection layer are formed together. in:

[0060] The scratch-resistant layer contains the following raw materials in parts by mass:

[0061] 90 parts of polyethylene terephthalate;

[0062] 7 parts of benzoyl peroxide;

[0063] Acrylonitrile 3 parts.

[0064] The aluminum foil is an aluminum ...

Embodiment 2

[0099] like figure 1 As shown, the water-resistant and anti-flatulence aluminum-plastic film for lithium battery packaging of the present invention has a scratch-resistant layer, an aluminum foil layer, a chemical protection layer, an absorption layer, and a barrier layer from the outside to the inside. Between the scratch-resistant layer and the aluminum foil layer, the chemical protection There are adhesive layers between the layer and the absorbing layer and between the absorbing layer and the barrier layer, and the aluminum foil layer and the chemical protection layer are formed together. in:

[0100] The scratch-resistant layer contains the following raw materials in parts by mass:

[0101] 93 parts of polyethylene terephthalate;

[0102] 10 parts of benzoyl peroxide;

[0103] Acrylonitrile 1 part.

[0104] The aluminum foil is an aluminum foil with a thickness of 40 microns.

[0105] The chemical protection layer is an inorganic-organosiloxane passivation solution. ...

Embodiment 3

[0139] Such as figure 1 As shown, the water-resistant and anti-flatulence aluminum-plastic film for lithium battery packaging of the present invention has a scratch-resistant layer, an aluminum foil layer, a chemical protection layer, an absorption layer, and a barrier layer from the outside to the inside. Between the scratch-resistant layer and the aluminum foil layer, the chemical protection There are adhesive layers between the layer and the absorbing layer and between the absorbing layer and the barrier layer, and the aluminum foil layer and the chemical protection layer are formed together. in:

[0140] The scratch-resistant layer contains the following raw materials in parts by mass:

[0141] 95 parts of polyethylene terephthalate;

[0142] 5 parts of benzoyl peroxide;

[0143] Acrylonitrile 2 parts.

[0144] The aluminum foil is an aluminum foil with a thickness of 50 microns.

[0145] The chemical protection layer is an inorganic-organosiloxane passivation solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com