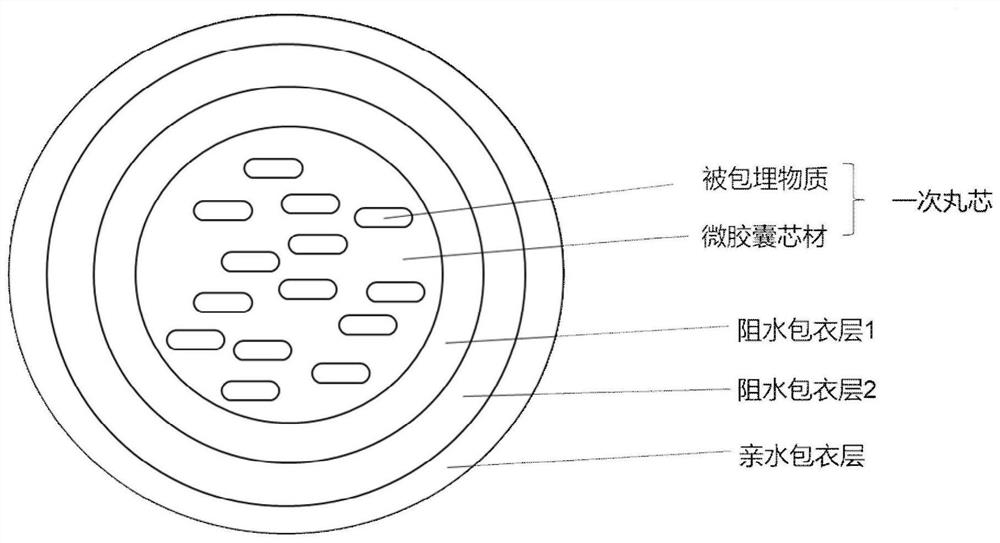

Microcapsule containing active substance and preparation method thereof

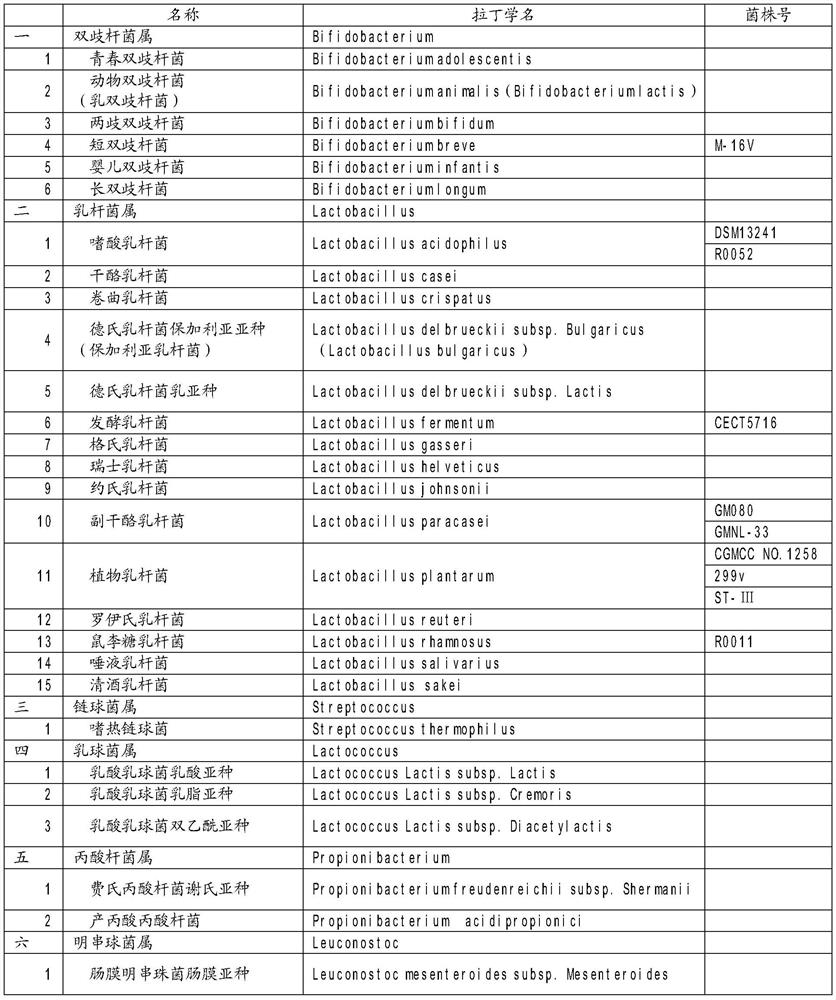

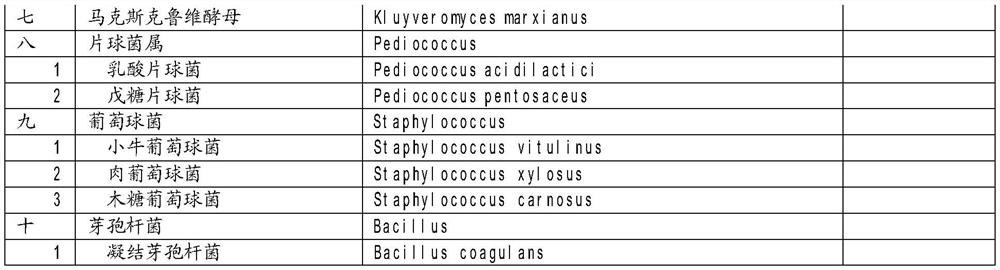

A technology of microcapsules and substances, applied in dairy products, food science, milk formulations, etc., can solve problems such as low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment L1~3

[0181] Embodiment L1~3 and comparative example thereof

Embodiment L1

[0183] Raw materials (based on 150kg dry microcapsules):

[0184] Ball core: Bacillus coagulans 200g, microcrystalline cellulose 800g, water 1000g.

[0185] Water blocking coating layer solution 1: 288g gliadin, 112g oleic acid, 1200g 75% ethanol.

[0186] Water-blocking coating layer solution 2: 54.4g of gliadin, 12.8g of glycerin, and 252.8g of 75% ethanol.

[0187] Hydrophilic coating layer solution: 110g pectin, 2090g water.

[0188] Preparation:

[0189] Mix Bacillus coagulans powder and microcrystalline cellulose evenly and add them to the wet granulation pot for pre-mixing for 10 minutes.

[0190] Turn on the cutting knife, turn on the peristaltic pump 20-30r / min, use 1000kg of water, and take 30mins. A soft material with a moisture content of 49.7% was obtained.

[0191] Start the granulator, feed the material at a speed of 30 rpm, adjust the extrusion speed to 50 rpm, and add soft material for 60 minutes. The strip-shaped soft material is extruded through the ori...

Embodiment L2

[0200] Raw materials (based on 150kg dry microcapsules):

[0201] Ball core: Bacillus coagulans 200g, microcrystalline cellulose 800g, water 1000g.

[0202] Water blocking coating layer solution 1: 270g prolamin, 105g oleic acid, 1125g 75% ethanol.

[0203] Water-blocking coating layer solution 2: 54.4g of gliadin, 12.8g of glycerin, and 252.8g of 75% ethanol.

[0204] Hydrophilic coating layer solution: 110g pectin, 2090g water.

[0205] Preparation:

[0206] Mix Bacillus coagulans powder and microcrystalline cellulose evenly and add them to the wet granulation pot for pre-mixing for 10 minutes.

[0207] Turn on the cutting knife, turn on the peristaltic pump 20-30r / min, use 1000kg of water, and take 30mins. A soft material with a moisture content of 49.7% was obtained.

[0208] Start the granulator, feed the material at a speed of 30 rpm, adjust the extrusion speed to 50 rpm, and add soft material for 60 minutes. The strip-shaped soft material is extruded through the or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com