Low-temperature cured single-component epoxy adhesive as well as preparation method and application thereof

An epoxy adhesive, one-component technology, used in epoxy resin adhesives, adhesives, organic chemistry, etc., can solve the problems of short service life, defective oxygen and moisture barrier properties, high transportation costs, and improve service life. , Solve the problem of storage stability and improve the effect of hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

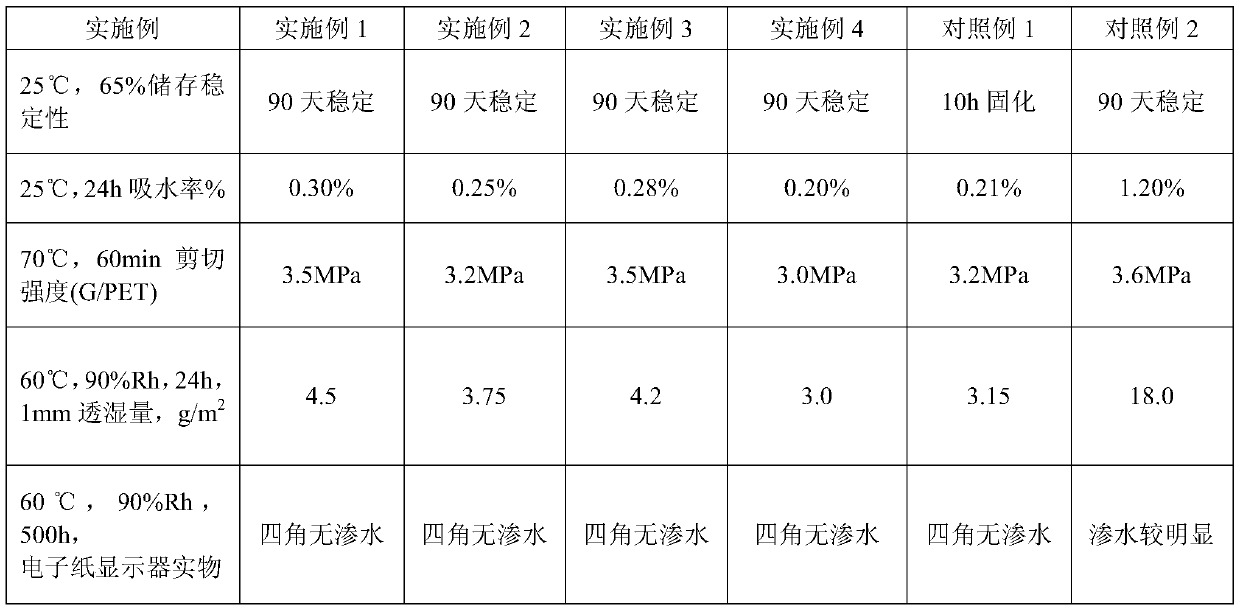

Examples

Embodiment 1

[0035] Prepare a low-temperature curing one-component epoxy adhesive, which is prepared according to the following method:

[0036] (1) Preparation of latent mercaptans: adding epoxy-containing compounds (1,3,5-triglycidyl isocyanurate) and thioacetic acid in sequence, wherein 1,3,5-triglycidyl The mol ratio of the epoxy group in the isocyanurate and thioacetic acid is 1:1.2, and tetrabutylammonium bromide is added as a catalyst (the quality of tetrabutylammonium bromide is 1,3,5-triglycidyl 0.5% of the total mass of isocyanurate and thioacetic acid), reacted at 95°C for 2h, and distilled under reduced pressure to obtain latent mercaptan TGICS;

[0037] (2) By weight, 45 parts of bisphenol A epoxy resin 128, 20 parts of bisphenol S epoxy resin, 20 parts of diphenol base hexafluoropropane diglycidyl ether, 15 parts of glycidyl propyl octafluoropentyl Add ether, 1.0 part of coupling agent (KH-560) and 1.0 part of thixotropic thickener (Cabot TS720) into the planetary reactor, s...

Embodiment 2

[0041] Prepare a low-temperature curing one-component epoxy adhesive, which is prepared according to the following method:

[0042] (1) Preparation of latent mercaptans: adding epoxy-containing compounds (trimethylolpropane triglycidyl ether) and monothioacid compounds (thiopropionic acid) in sequence, wherein trimethylolpropane triglycidyl The mol ratio of the epoxy group in the ether to thiopropionic acid is 1:1.5, adding tetrabutylammonium bromide is a catalyst (the quality of tetrabutylammonium bromide is trimethylolpropane triglycidyl ether and thiosulfate 1.0% of the total mass of propionic acid), reacted at 85°C for 6h, and distilled under reduced pressure to obtain latent mercaptan TMPEGS;

[0043](2) By weight, 20 parts of UVR6103 epoxy resin, 10 parts of bisphenol F epoxy resin, 25 parts of 4080E hydrogenated bisphenol A epoxy resin, 40 parts of octafluorobiphenyl diglycidyl ether, 5 parts of glycidyl Glycerin propyl dodecafluoroheptyl ether, 2.0 parts of coupling a...

Embodiment 3

[0047] Prepare a low-temperature curing one-component epoxy adhesive, which is prepared according to the following method:

[0048] (1) Preparation of latent mercaptans: Add epoxy-containing compound (pentaerythritol tetraglycidyl ether) and monothioacid compound (thioacetic acid) in sequence, wherein the epoxy group in pentaerythritol tetraglycidyl ether and thioxate The molar ratio of acetic acid is 1:1.3, add tetrabutylammonium bromide as catalyst (the quality of tetrabutylammonium bromide is 0.8% of the total mass of pentaerythritol tetraglycidyl ether and thioacetic acid), and react at 90°C for 4h , distillation under reduced pressure, obtain latent mercaptan PETEGS;

[0049] (2) In parts by weight, 25 parts of UVR6103 epoxy resin, 40 parts of 4080E hydrogenated bisphenol A epoxy resin, 25 parts of two-(hexafluorohydroxypropyl) benzene diglycidyl ether, 10 parts of glycidyl propyl Hexafluorobutyl ether, 1.0 parts of coupling agent (KH-563) and 3.0 parts of thixotropic th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com