Cardanol modified phenolic amide curing agent and preparation method thereof

A technology of phenalkamide and cardanol, which is applied in the preparation of carboxylic acid amide, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of uncurable and limited usability, and achieve good adhesion, toughness and anti-corrosion performance. Good, long-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

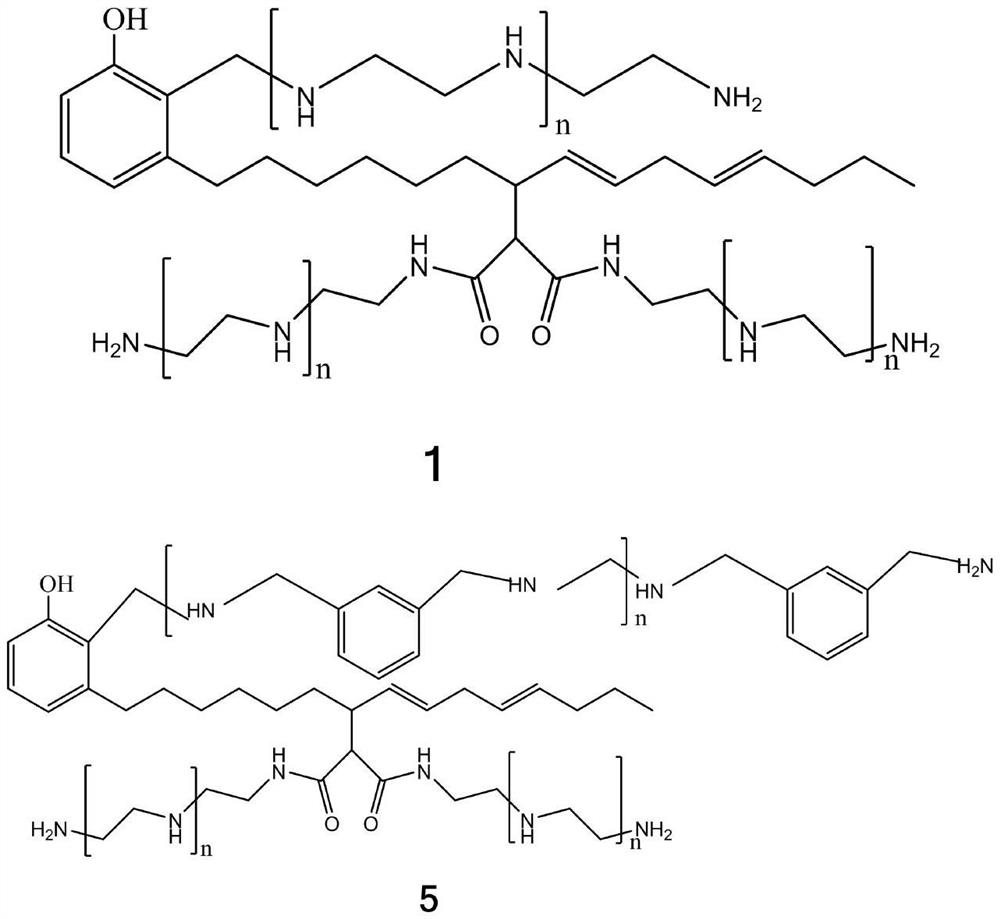

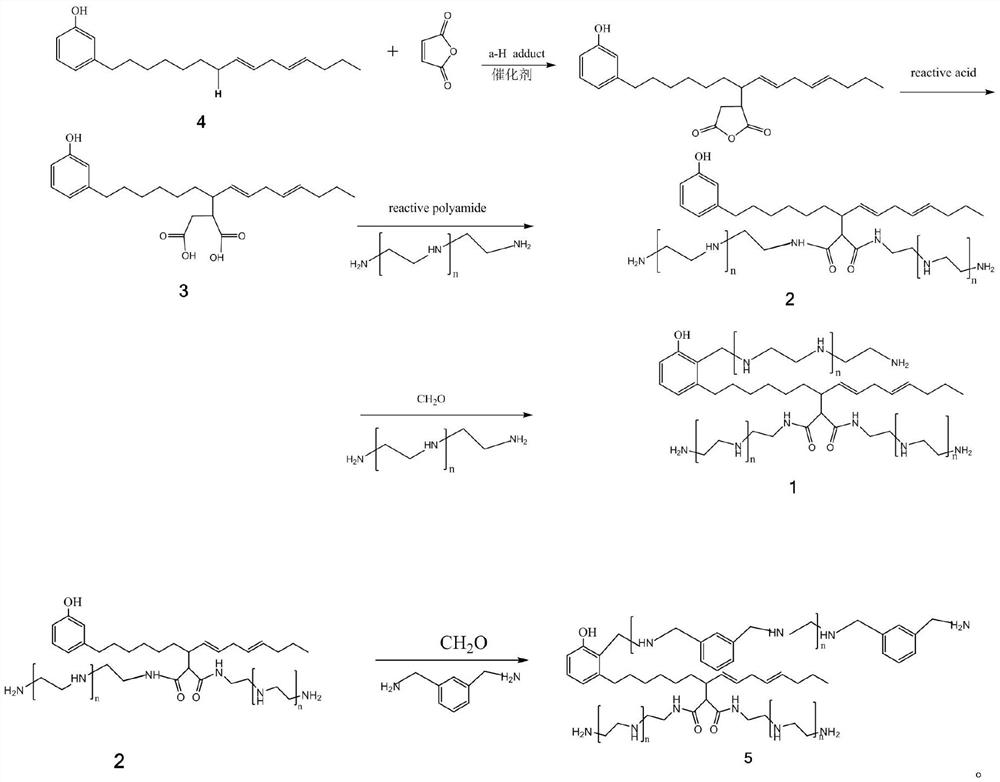

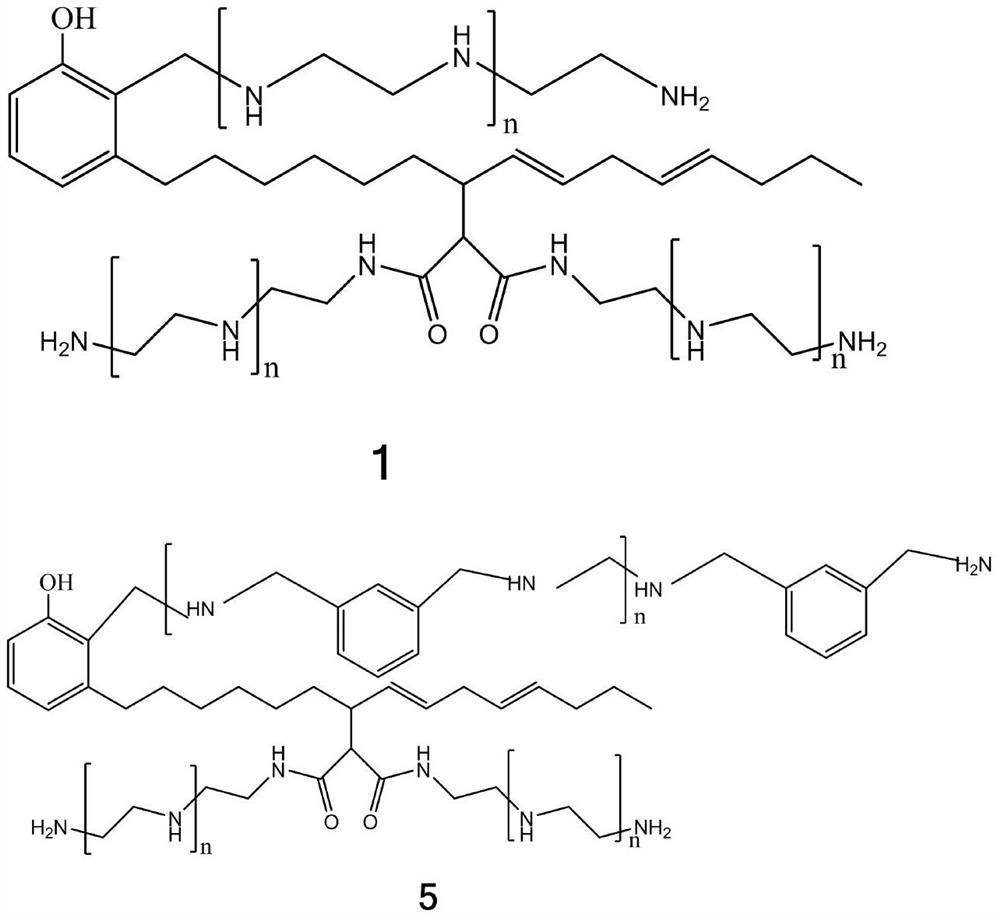

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Preparation of compound of formula (3)

[0025] Put 150g cardanol, 53.9g maleic anhydride into the reaction flask, add 0.75g catalyst cobalt isooctanoate and 9g pyrrolidone, carry out nitrogen replacement and be warmed up to 150-190 DEG C reaction, keep warm for 4-5hr, cool down, add xylene 90g, water 90g, stand for stratification, liquid separation, the organic layer is desolvated under reduced pressure at 100-120°C to obtain the compound represented by formula (3); analysis result: acid value is 230mgKOH / g, iodine value is 110g / 100g.

Embodiment 1a

[0026] Example 1a: Preparation of compound of formula (3)

[0027] Put 150g cardanol, 63.7g maleic anhydride in the reaction flask, add 1.0g catalyst cobalt naphthenate and solvent 10g pyrrolidone, carry out nitrogen replacement and be warmed up to 150-190 ℃ reaction, keep warm for 5-7hr, cool down, add ethyl acetate 100g, 100g water, stand for stratification, liquid separation, and desolventizing under reduced pressure at 100-120°C to obtain the compound shown in formula (3); analysis result: acid value is 236mgKOH / g, iodine value is 105g / 100g.

Embodiment 2

[0028] Example 2: Preparation of compound represented by formula (2)

[0029] 100g of compound shown in formula (3), 42.2g of diethylenetriamine (DETA) were put into the reaction flask, the temperature was raised to 150-160 DEG C for reaction, the temperature was kept for 4-5hr, and the temperature was lowered to obtain the compound of formula (2). Analysis result: amine The value was 510 mgKOH / g; the viscosity was 22000 cp@25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com