A kind of low-temperature polymer conductive silver paste and preparation method thereof

A technology of conductive silver paste and polymer, which is used in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., which can solve problems such as mass production capacity, adhesion, weather resistance and stability gaps , to achieve the effect of non-toxic light transmittance, good printability, and soft matt feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

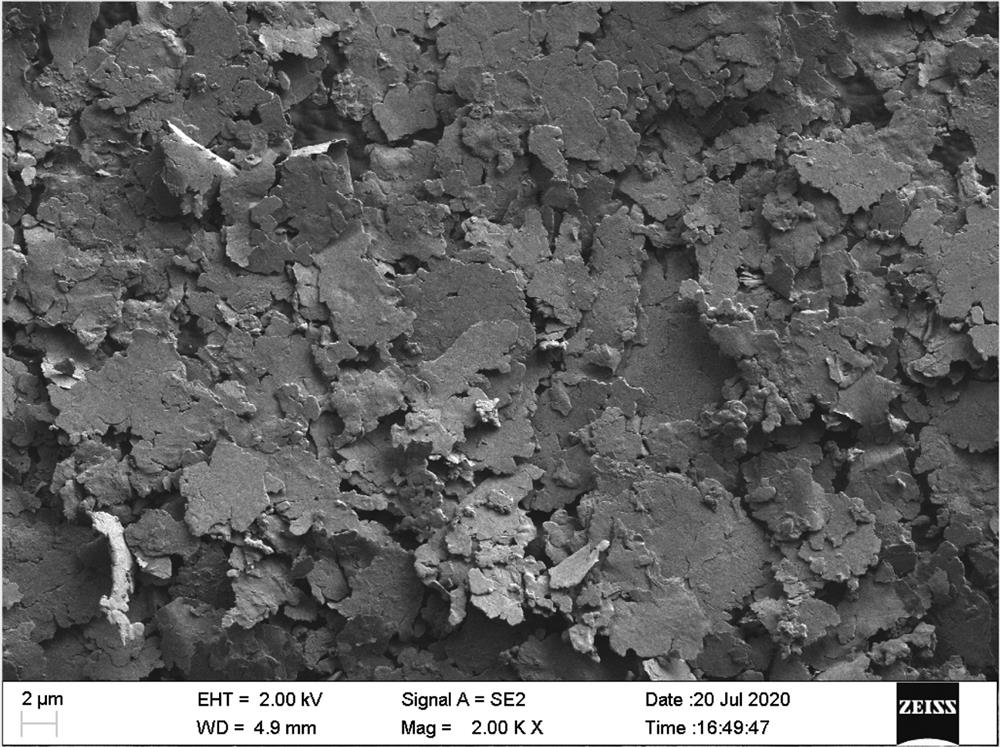

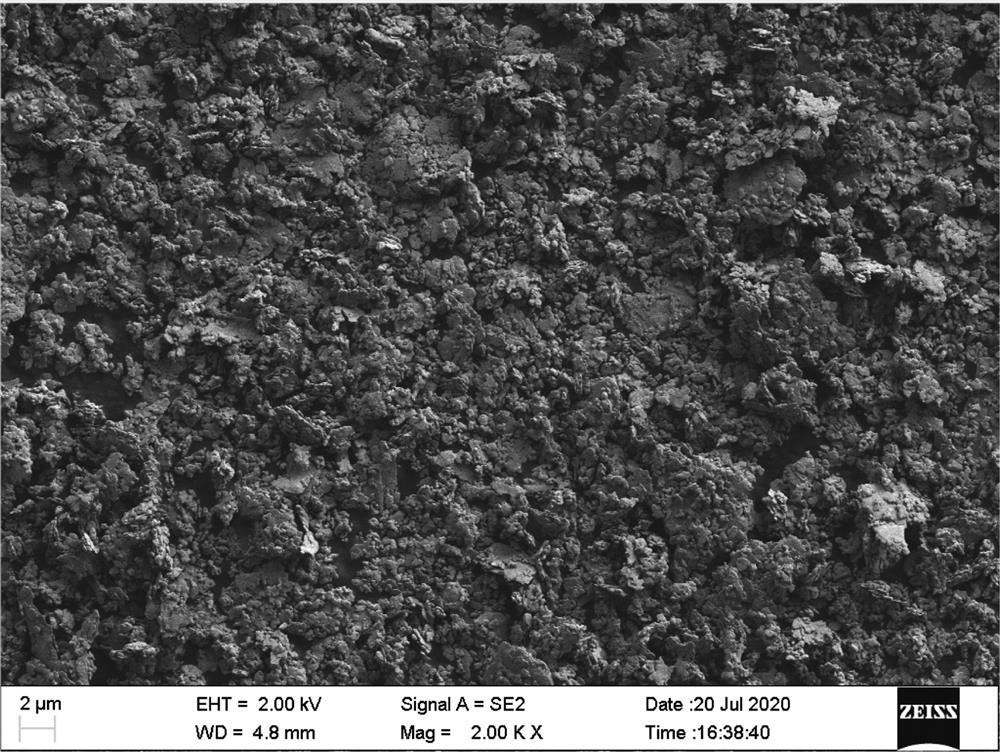

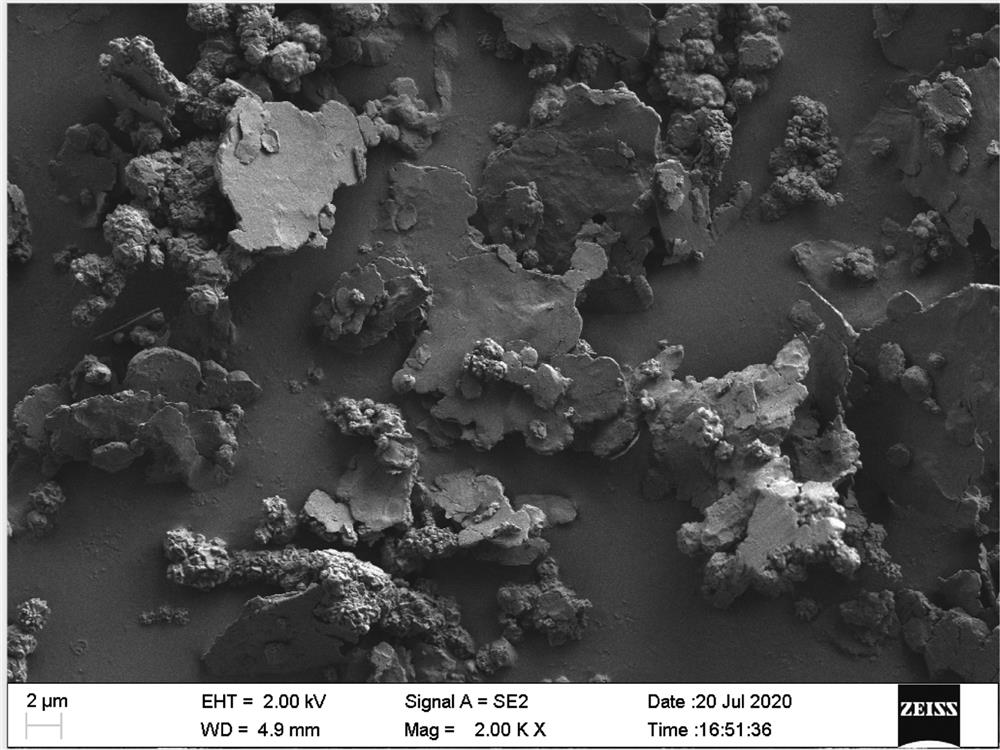

Image

Examples

Embodiment 1

[0032] The conductive silver paste of the present embodiment is made up of following mass percentage material: flaky silver powder SF-1# 38%, SF-2#1%, flaky nickel powder NF-1# 4%, organic vehicle 1# 46%, organic Bentonite 0.8%, polyethylene micropowder wax 0.5%, YL-2 glass resin 0.5%, 9100 varnish 0.7%, dibasic ester (DBE) 8.5%.

[0033] The D50 values of the flaky silver powder SF-1# and SF-2# are 3.49 μm and 1.46 μm respectively, the D50 value of the flaky nickel powder NF-1# is 8.28 μm, and the organic carrier 1# is 12 % Dow VAGH-004 resin is fully stirred and dispersed in 88% DBE.

[0034] Above-mentioned conductive silver paste preparation method comprises the following steps:

[0035] Step 1, premixing of slurry: Firstly, organic carrier 1#, organic bentonite, polyethylene micropowder wax, YL-2 glass resin, 9100 varnish, and DBE are fully dissolved and mixed in a container using a high-speed disperser and dispersed evenly. Then pour in the flaky silver powder SF-1#,...

Embodiment 2

[0043] The conductive silver paste of the present embodiment is made up of following mass percentage material: flaky silver powder SF-1# 38%, SF-2#1%, flaky nickel powder NF-1# 4%, organic carrier 1# 42%, organic Carrier 2# 7%, organic bentonite 0.8%, polyethylene micronized wax 0.5%, YL-2 glass resin 0.5%, 9100 varnish 0.7%, dibasic ester (DBE) 5.5%.

[0044] The D50 values of the flaky silver powder SF-1# and SF-2# are 3.49 μm and 1.46 μm respectively, the D50 value of the flaky nickel powder NF-1# is 8.28 μm, and the organic carrier 1# is 12 % Dow VAGH-004 resin is fully stirred and dispersed in 88% DBE, and the organic vehicle 2# is 20% Dow VAGH-003A resin, fully stirred and dispersed in 80% DBE.

[0045] Above-mentioned conductive silver paste preparation method comprises the following steps:

[0046] Step 1, premixing of the slurry: First, fully dissolve the organic carrier 1#, organic carrier 2#, organic bentonite, polyethylene micronized wax, YL-2 glass resin, 9100 ...

Embodiment 3

[0050] The conductive silver paste of the present embodiment is made up of following mass percentage material: flaky silver powder SF-1# 38%, SF-2#1%, flaky nickel powder NF-1# 4%, organic carrier 1# 42%, organic Carrier 3# 7%, organic bentonite 0.8%, polyethylene micronized wax 0.5%, YL-2 glass resin 0.5%, 9100 varnish 0.7%, dibasic ester (DBE) 5.5%.

[0051] The D50 values of the flaky silver powder SF-1# and SF-2# are 3.49 μm and 1.46 μm respectively, the D50 value of the flaky nickel powder NF-1# is 8.28 μm, and the organic carrier 1# is 12 % Dow VAGH-004 resin is fully stirred and dispersed in 88% DBE, and the organic vehicle 3# is 20% Dow VAGH resin, fully stirred and dispersed in 80% DBE.

[0052] Above-mentioned conductive silver paste preparation method comprises the following steps:

[0053] Step 1, premixing of the slurry: First, fully dissolve the organic carrier 1#, organic carrier 3#, organic bentonite, polyethylene micronized wax, YL-2 glass resin, 9100 varni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com