Thermosetting two-component coating composition and coated articles

A two-component coating, thermosetting technology, applied in the coating and other directions, to achieve the effect of stable extinction and excellent coating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

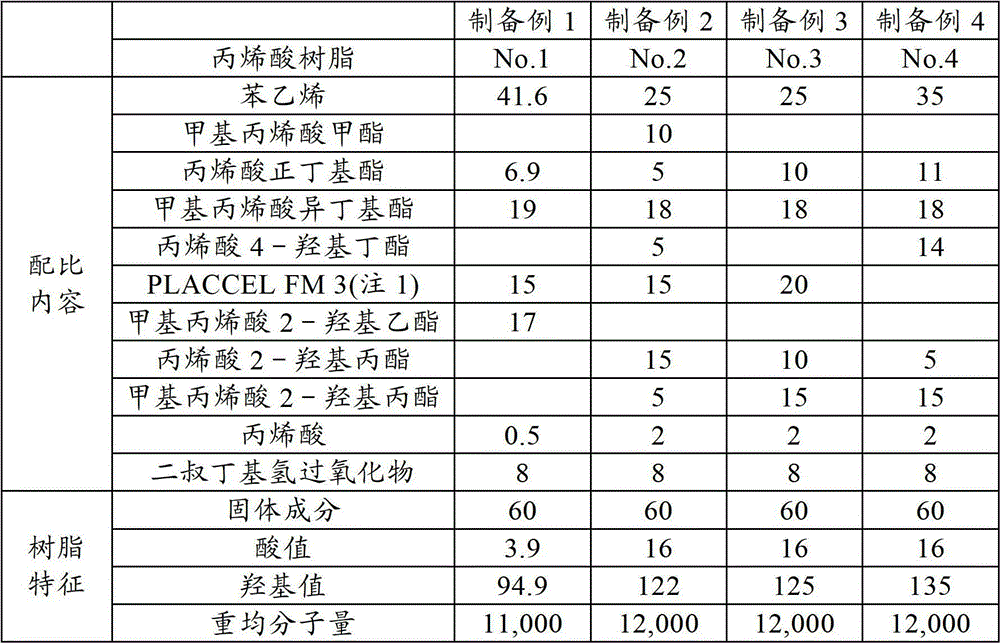

[0092] The preparation of preparation example 1 acrylic resin No.1 solution

[0093] 28 parts of SWASOLVE 1000 (manufactured by COSMO Petroleum Co., Ltd., aromatic hydrocarbon solvent), 85 parts of toluene, 41.6 parts of styrene, 6.9 parts of n-butyl acrylate, 19 parts of isobutyl methacrylate, PLACCEL FM 3 ( Note 1) 15 parts, 17 parts of 2-hydroxyethyl methacrylate, 0.5 parts of acrylic acid, and 8 parts of di-tert-butyl hydroperoxide were reacted at 110°C under nitrogen to obtain an acid value of 3.9 mgKOH / g and a hydroxyl value of 94.9 mgKOH / g. Acrylic resin No.1 with a weight average molecular weight of 11,000.

[0094] (Note 1) PLACCEL FM 3: manufactured by DIACEL Chemical Industry Co., Ltd., brand name, ε-caprolactone-modified vinyl monomer of 2-hydroxyethyl acrylate.

[0095] Preparation Examples 2-4 Acrylic Resin No.2-No.4

[0096] Acrylic resins No. 2 to No. 4 were obtained in the same manner as in Preparation Example 1 except that the monomer mixture of the compon...

preparation example 5

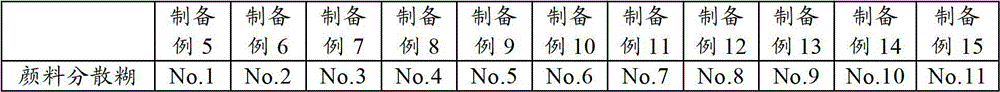

[0099] Preparation Example 5 Preparation Example of Pigment Dispersion Paste No.1

[0100] Mix 1100 parts of acrylic resin No. 1100 (60 parts of solid content), 5 parts of Monarch 1300 (Note 2), 100 parts of LAKABAR SF (Note 3), and MIZUKASIL P-526 (Note 8) obtained in Preparation Example 1. ) 10 parts, the solid content was adjusted with SWASOLVE 1000 (manufactured by COSMO Petroleum Co., Ltd., aromatic hydrocarbon solvent), put into a ball mill and stirred for 6 hours to obtain pigment dispersion paste No. 1 with a solid content of 60%.

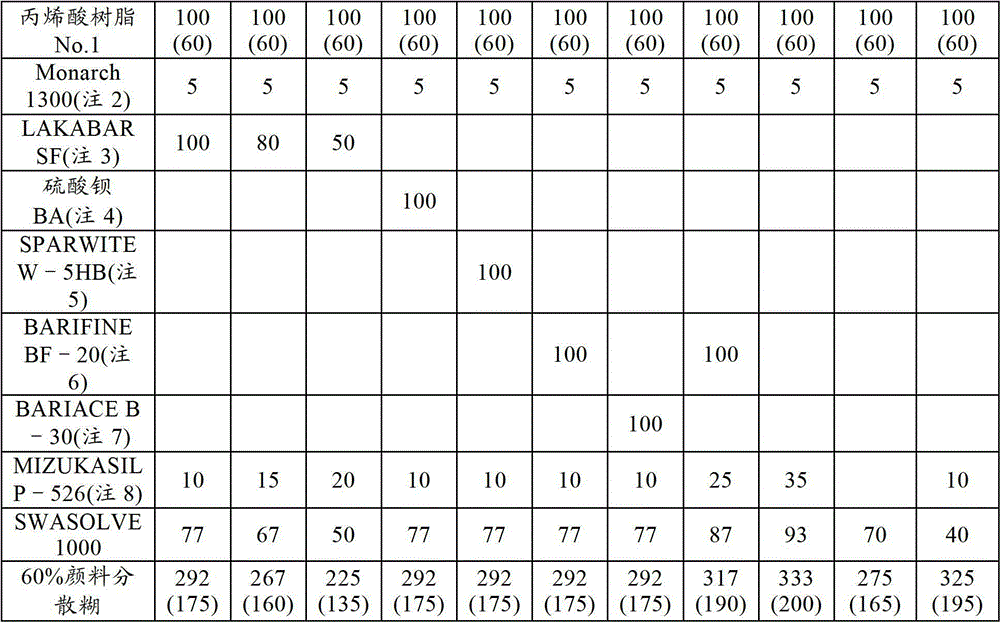

[0101] Preparation Example 6~15 Preparation Example of Pigment Dispersion Paste No.2~No.11

[0102] Pigment dispersion pastes No. 2 to No. 11 were obtained in the same manner as in Preparation Example 5 except that the content of the compounding ratio in Table 2 was adopted.

[0103] Table 2

[0104]

[0105]

[0106] ( ) indicates solid content

[0107] (Note 2) Monarch 1300: manufactured by Cabot Corporation, trade name, carbon b...

Embodiment 1

[0115] Embodiment 1 coating composition No.1

[0116] Mix Acrylic Resin No. 119 parts (solid content) obtained in Preparation Example 1, Sumidur N3300 (Note 9) 21 parts (solid content), Pigment Dispersion Paste No. 1175 parts (solid content) obtained in Preparation Example 5, BYK -410 (Note 11) 0.8 part was adjusted to 60 mass % of solid content, and the coating composition No. 1 was obtained.

[0117] Embodiment 2~14 coating composition No.2~No.14

[0118] Except having used the compounding content of Table 3, it carried out similarly to Example 1, and obtained the coating composition No.2-No.14 of 60 mass % of solid content. The results obtained by performing tests according to the following "production of test panels" are also given.

[0119] table 3

[0120]

[0121]

[0122] The value in the ratio table indicates the solid content

[0123] (Note 9) Sumidur N3300: manufactured by Sumika Bayer Polyurethane Co., Ltd., trade name, trimeric isocyanate body of 1,6-hex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com