Actinic ray curable composition and film using same

An active energy ray, curable composition technology, applied in the direction of coating, can solve the problems of coating film defects, peeling charge, yield reduction, etc., and achieve the effects of excellent anti-static and anti-glare properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

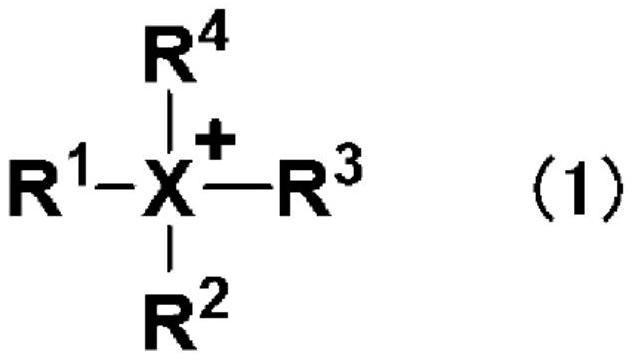

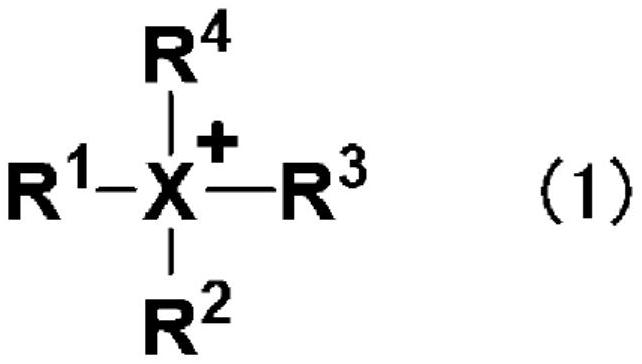

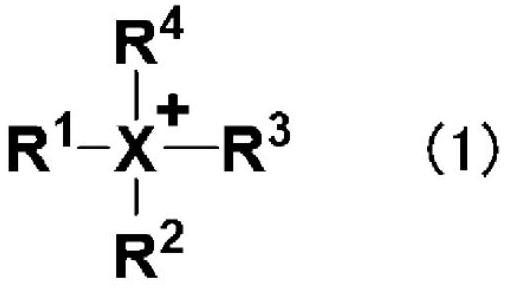

[0078] Pentaerythritol tetraacrylate (hereinafter referred to as "PETTA") and pentaerythritol triacrylate (hereinafter referred to as "PETA") equal mixture 40 parts by mass, urethane acrylate (1) (dipentaerythritol pentaacrylate ester and isophorone diisocyanate, solid content 100% by mass, hereinafter abbreviated as "UA(l)".) 20 parts by mass, urethane acrylate (2) (polytetramethylene glycol Reactant with isophorone diisocyanate and 2-hydroxyethyl acrylate, number average molecular weight; 1,600, solid content 100% by mass, hereinafter referred to as "UA (2)".), epoxy acrylate (1) ( Methyl isobutyl ketone solution of a reaction product of polyglycidyl methacrylate and acrylic acid, solid content 50% by mass, viscosity 1,000 mPa·s, hereinafter referred to as "EA (1)".) 40 parts by mass, ethanol 144 After fully mixing 5 parts by mass and 5 parts by mass of 1-hydroxycyclohexyl phenyl ketone, mix antistatic agent (B) (in formula (1), X represents phosphorus atom, R 1 ~R 3 Repre...

Embodiment 2~16、 comparative example 1~6

[0080] The active energy ray-curable compound (A) and the antistatic agent (B) used were changed as shown in Tables 1 to 4, except that the types and usage amounts of the active energy ray-curable compound (A) and antistatic agent (B) were changed in the same manner as in Example 1 to prepare an active energy ray-curable compound (A) and antistatic agent (B). sex composition.

[0081] [Preparation of samples for evaluation]

[0082] The active energy ray-curable compositions obtained in Examples and Comparative Examples were coated on a polymethyl methacrylate film having a thickness of 5 μm using a bar coater, and dried at 60° C. for 1 minute. Under a nitrogen atmosphere, use an ultraviolet irradiation device (manufactured by EYEGRAPHICS Co., Ltd., high-pressure mercury lamp) to irradiate at a light intensity of 75 mJ / m 2 The irradiation was performed twice to obtain a polymethyl methacrylate film having a cured coating film as a sample for evaluation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com