Active energy ray-curable composition and film using same

A technology of active energy rays and curable compositions, applied in the direction of coating, etc., can solve the problems of low cost and high precision requirements, coating film defects, easy to generate peeling static electricity, etc., to achieve the appearance of the coating film and antistatic excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0085] (Manufacturing example 1: Synthesis of urethane acrylate (A2-1) composition)

[0086] 55.5 parts by mass of butyl acetate, 222 parts by mass of isophorone diisocyanate (hereinafter referred to as "IPDI"), 222 parts by mass of p-methoxyphenol 0.5 parts by mass, 0.5 parts by mass of dibutyltin diacetate, after heating up to 70°C, dropwise added pentaerythritol triacrylate (hereinafter referred to as "PE3A") / pentaerythritol tetraacrylate (hereinafter referred to as "PE4A") .) 993.4 parts by mass of 80% by mass butyl acetate solution of the mixture (the mixture of mass ratio 75 / 25). After the dropwise addition, react at 70°C for 3 hours, and then proceed until the isocyanate group is represented by 2250cm -1 Until the infrared absorption spectrum disappears, after desolventization based on vacuum drying, the urethane acrylate (A2-1) / PE4A mixture (the mixture of mass ratio 80 / 20, the non-volatile content is 100% by mass or less, and It is described as "urethane acrylate (A...

manufacture example 2

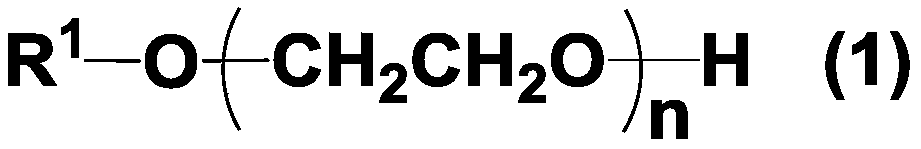

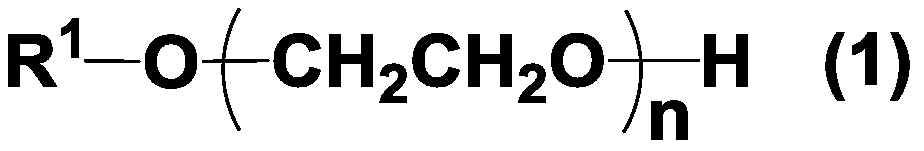

[0087] (Production example 2: Production of resin (B-1) having an alicyclic structure and a quaternary ammonium salt)

[0088] Into a flask equipped with a stirring device, a reflux condenser, and a nitrogen introduction pipe, nitrogen gas was introduced to replace the air in the flask with nitrogen. Thereafter, 54.2 parts by mass of 2-(methacryloyloxy)ethyltrimethylammonium chloride, 19.9 parts by mass of cyclohexyl methacrylate, methoxypolyethylene glycol methacrylate ("BLEMMERPME-1000" manufactured by NOF Corporation; number of repeating units n≈23, molecular weight 1,000) 24.9 parts by mass, 0.5 parts by mass of methacrylic acid, 50 parts by mass of methanol (hereinafter, abbreviated as "MeOH"), and propylene glycol 10 parts by mass of monomethyl ether (hereinafter, abbreviated as "PGME"). Then, after dripping the solution which melt|dissolved 0.1 mass part of polymerization initiators (azobisisobutyronitrile) in 2.4 mass parts of PGME over 30 minutes, it was made to reac...

Embodiment 1

[0118] 65 parts by mass of PE4A, 35 parts by mass of the urethane acrylate (UA) composition obtained in Production Example 1 (28 parts by mass of (UA), 7 parts by mass of PE4A), 10 parts by mass of 1-hydroxycyclohexyl phenyl ketone , 5 parts by mass of the solid content of the resin (B-1) obtained in Production Example 2, methyl ethyl ketone (hereinafter, abbreviated as "MEK"), dimethyl carbonate (hereinafter, abbreviated as "DMC"), PGME , 2-phenoxyethanol (hereinafter, abbreviated as "PhG") is diluted so that the solvent composition becomes MEK / DMC / PGME / MeOH / PhG=67.5 / 19.9 / 7.5 / 4.6 / 0.5 (mass ratio) The method was adjusted and uniformly mixed to obtain an active energy ray-curable composition (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com