System and method for multi-beam synthesizing and focusing type roll surface texturing laser processing

A laser processing and multi-beam technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of irregular distribution of micro pits, low energy of single beam, and inability to texture, etc. The spacing can be controlled in real time, the effect of increasing the textured area and increasing the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

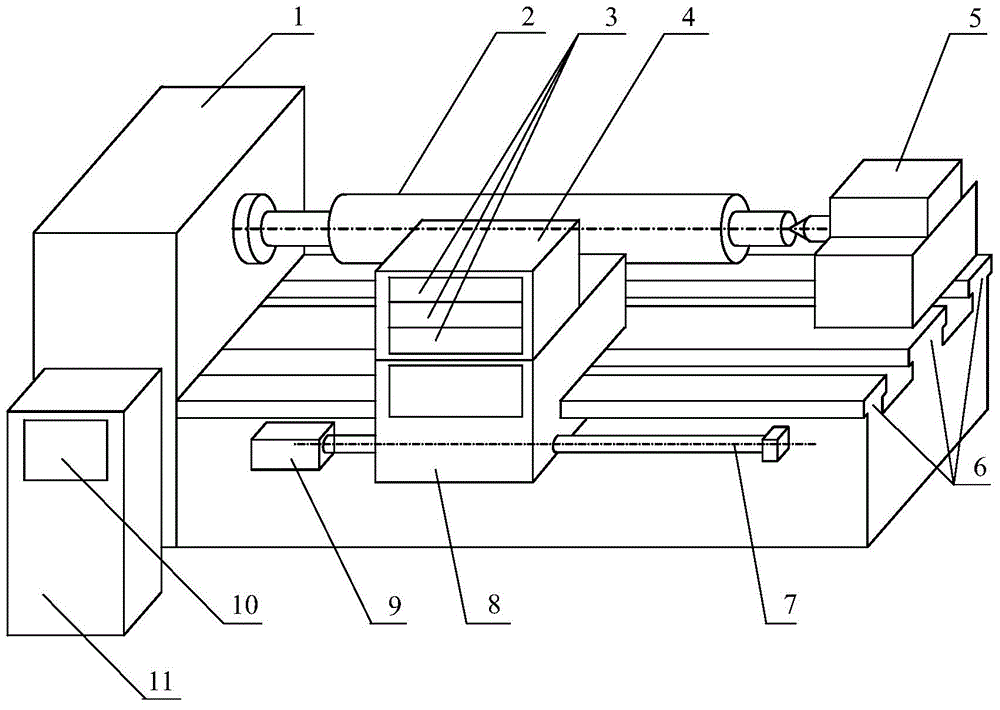

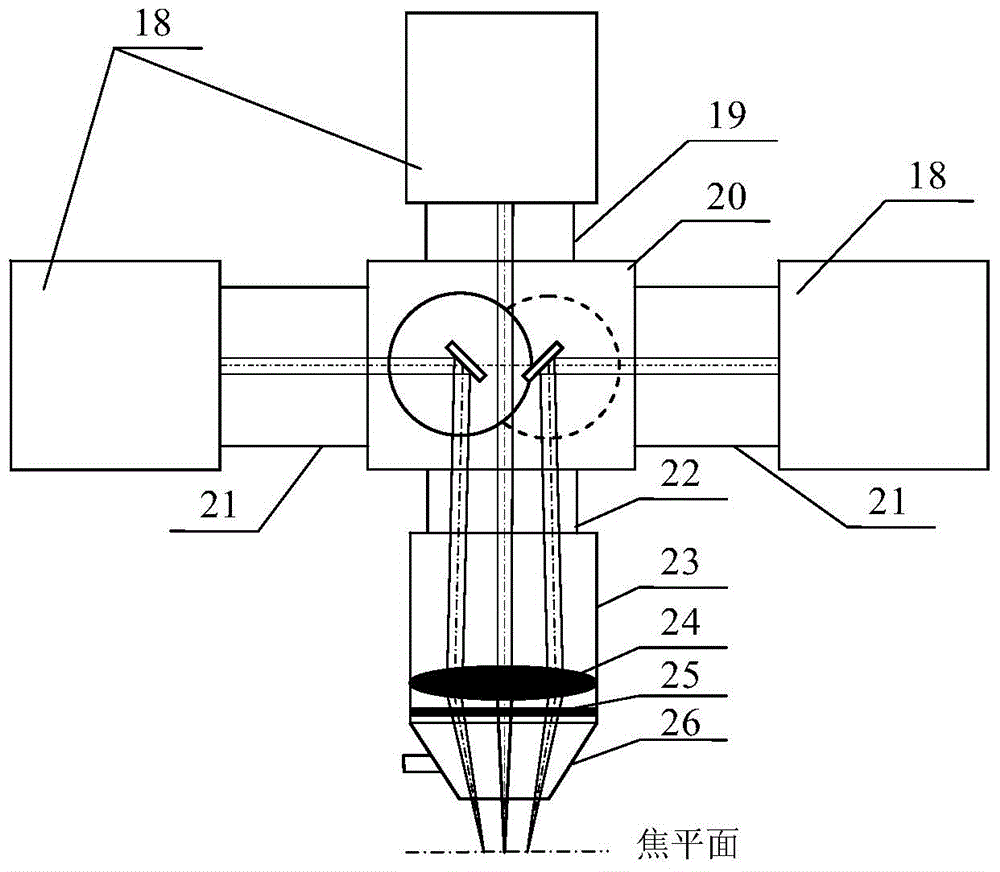

[0048] see Figure 1-7 , the embodiment of the present invention provides a multi-beam light synthesis focusing laser processing system for surface texturization of rollers, including machine tools, laser processing devices, multi-beam light synthesis focusing devices 3 and a control system;

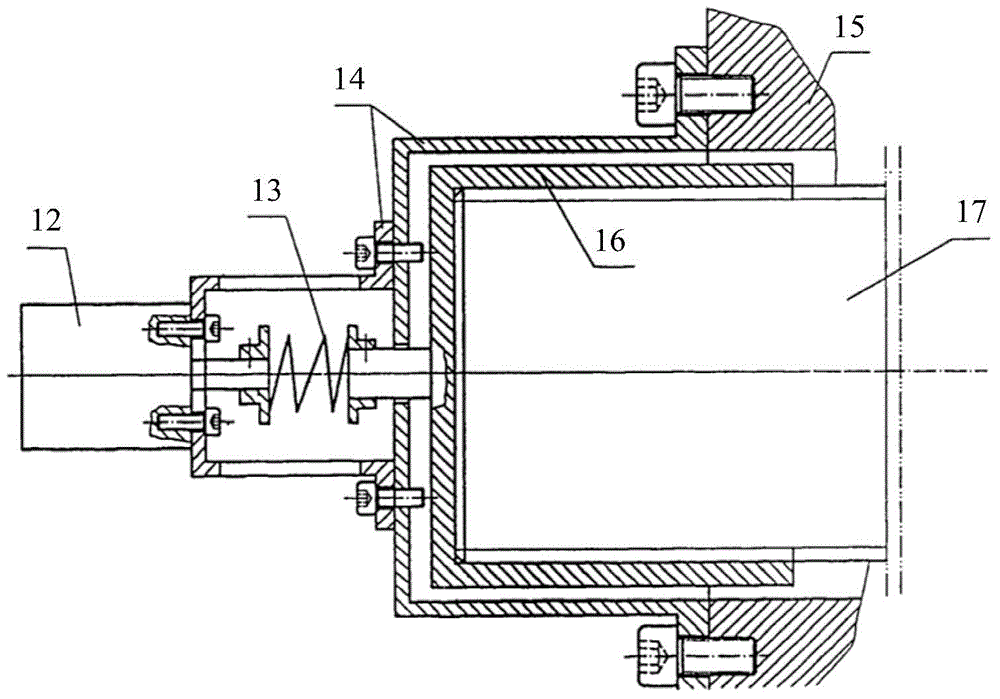

[0049] see figure 1 , the machine tool equipment is used to drive the roller workpiece 2 to rotate, including a frame and a machine tool spindle 17 arranged on the frame and a spindle motor that drives the machine tool spindle 17 to rotate; the machine tool equipment consists of a machine tool head 1, a machine bed and a control cabinet 11 Composed of three parts, it has a structure similar to that of a two-dimensional CNC lathe; the head of the machine tool 1 includes a spindle frequency conversion motor (that is, a spindle motor), a machine tool spindle gearbox 15, a machine tool spindle 17 and a machine tool spindle sleeve 16, high-precision and high-resolution Incremental encoder 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com