Multi-beam light synthesis focusing device

A focusing device, multi-beam technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of inability to texturize, low energy of a single beam of light, etc., to improve the processing speed and increase the texturing area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

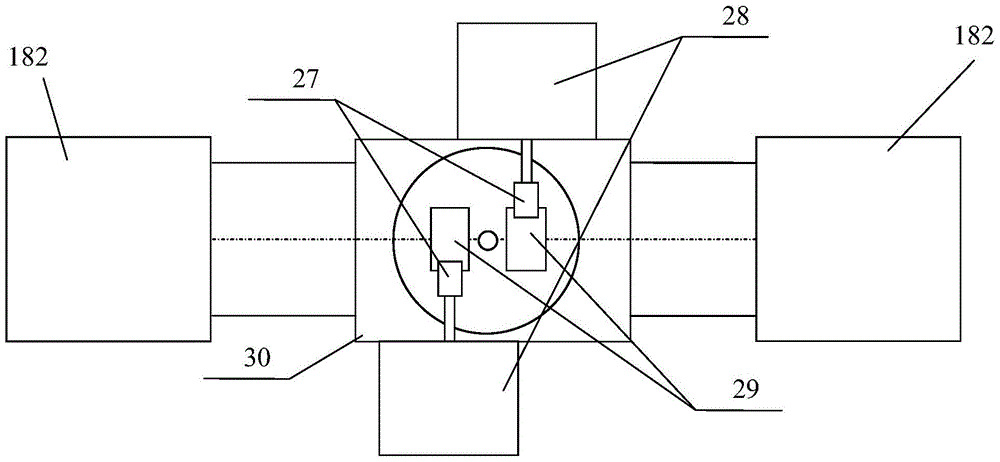

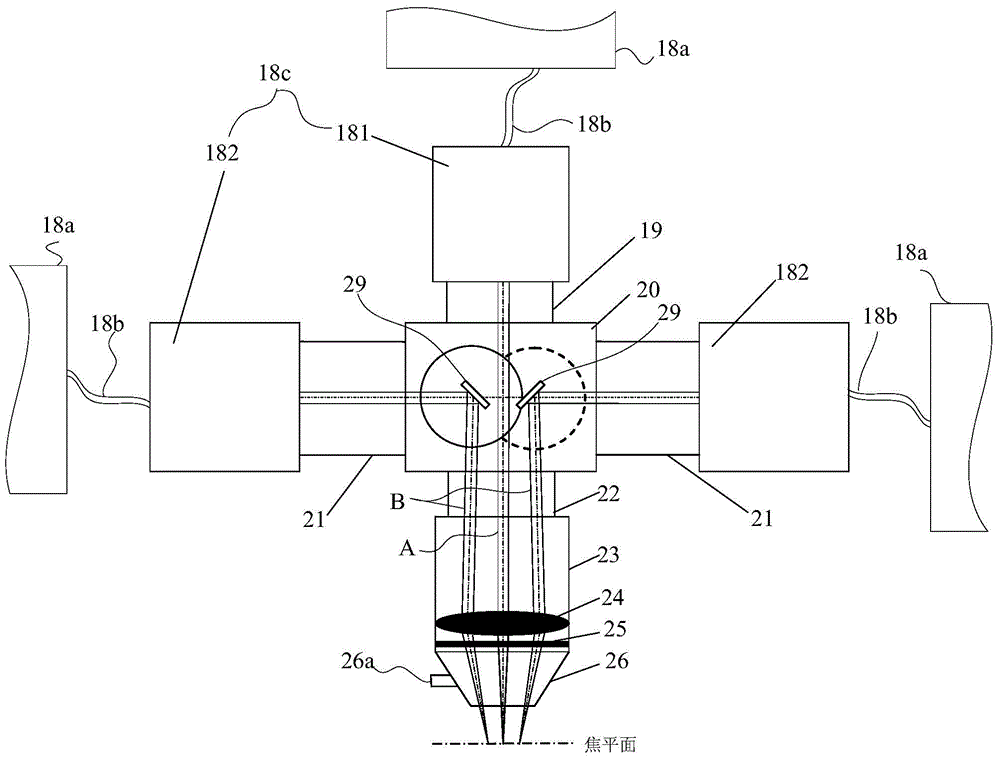

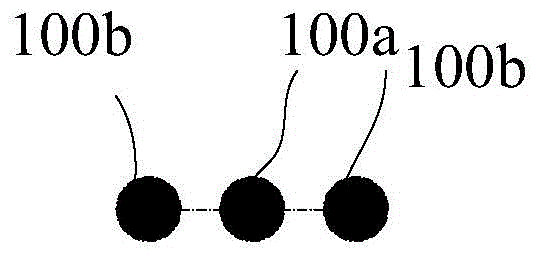

[0045] Such as figure 1 , figure 2 As shown, the embodiment of the present invention provides a multi-beam light synthesis focusing device, including a focusing component and at least one multi-beam light synthesis component, where the multi-beam light synthesis refers to the synthesis of more than two beams of light;

[0046] The multi-beam light combining component is used to combine more than two beams of incident light from different directions, and the angle between the combined beams is between 0 and 30 degrees; it includes at least two lasers 18a, and the number of optical fibers 18b equal to the number of lasers 18a , a collimator 18c equal in number to the laser 18a and a deflection assembly 20; each optical fiber is connected to a laser and a collimator for flexible transmission of the light beam emitted by the laser 18a, and the collimator 18c Used to collimate the beam transmitted by the optical fiber 18b; the deflection assembly 20 includes at least one reflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com