Primer for spraying automobile wheel hub and preparation method of primer

A technology for automobile wheel hubs and primers, which is applied to primers, coatings, and devices for coating liquid on the surface, etc., which can solve the problems of cost, general performance of finished products, and cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

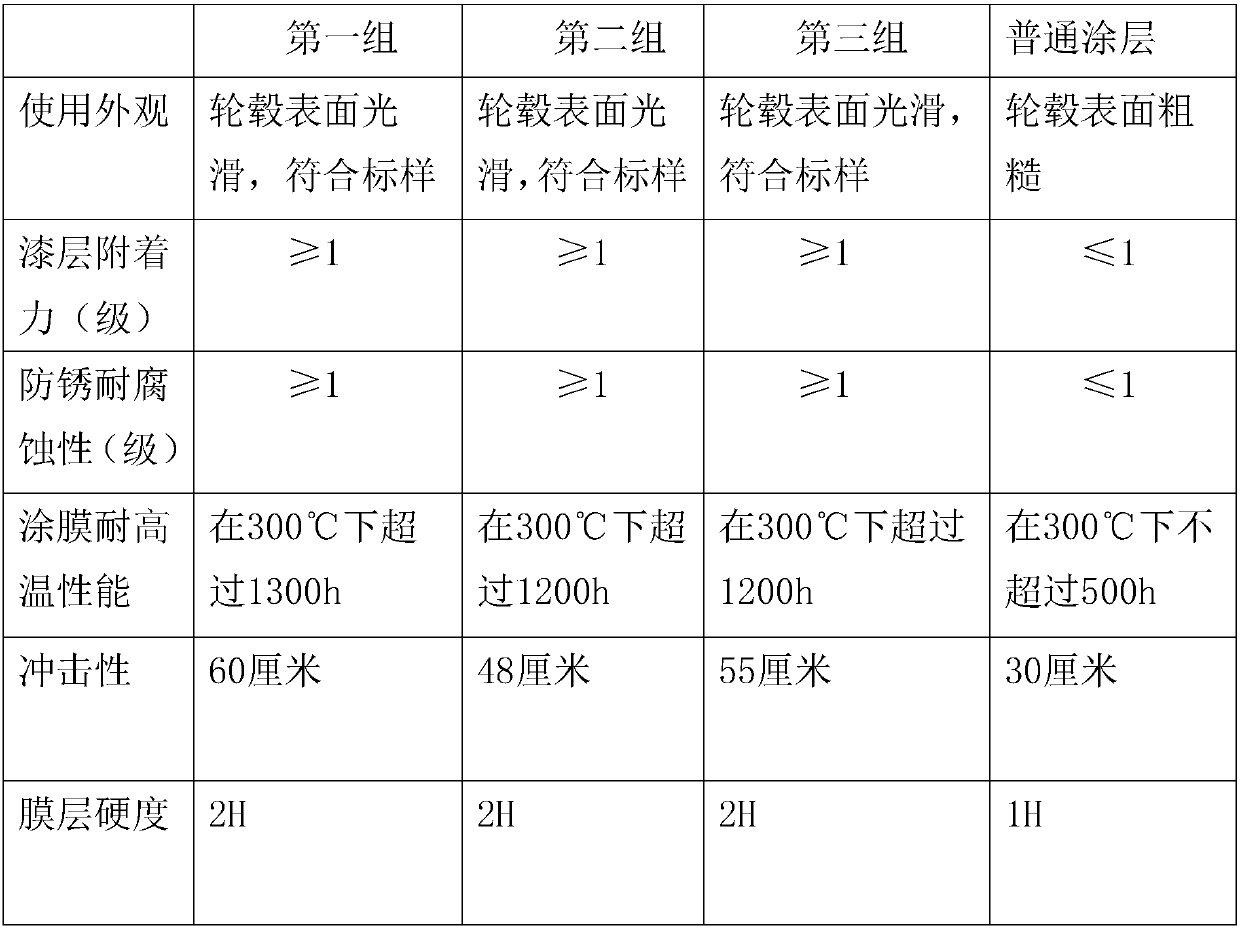

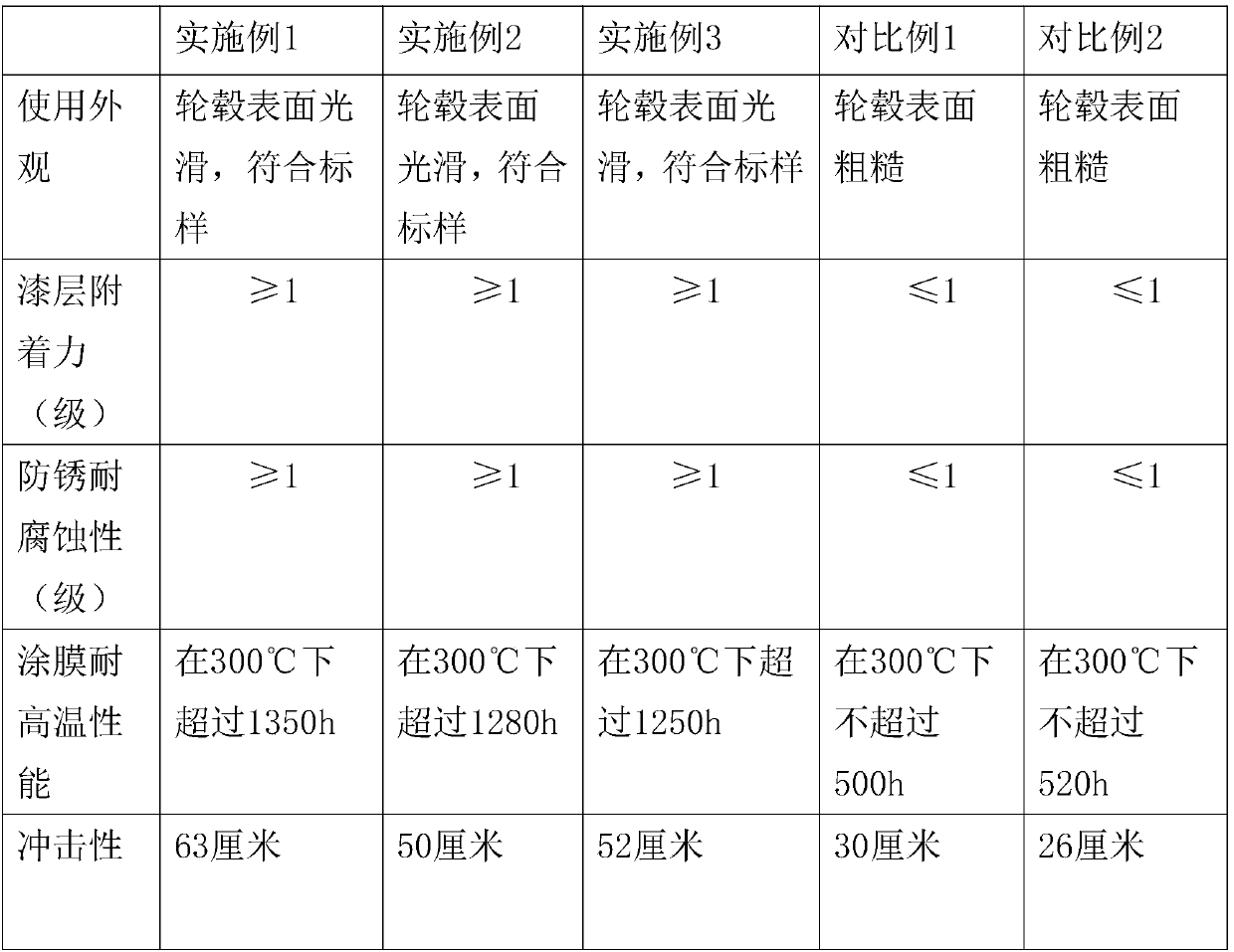

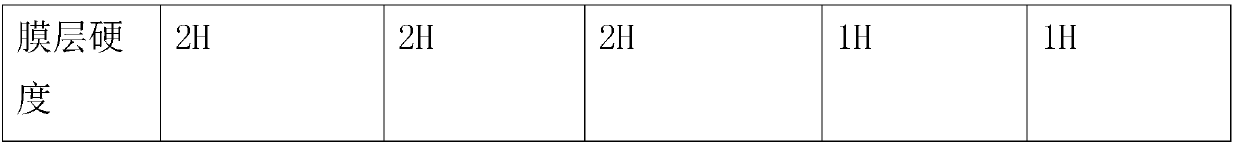

Examples

Embodiment 1

[0076] Embodiment 1: A kind of primer for automobile wheel hub spraying, by mass fraction: including 0.3 parts of graphene, 33 parts of thermoplastic acrylic resins, 10 parts of titanium dioxide, 0.1 parts of graphene dispersant BYK90760.1 parts, titanium dioxide dispersant BYK- 1630.5 parts, 0.1 parts of defoamer, 29 parts of xylene.

[0077] A preparation method for a primer for automobile wheel hub spraying, comprising:

[0078] Thinning thermoplastic acrylic resins with xylene;

[0079] Add graphene dispersant and graphene to disperse;

[0080] Add titanium dioxide dispersant and titanium dioxide, continue to disperse;

[0081] A defoamer is added to make the primer.

Embodiment 2

[0082] Embodiment 2: A kind of primer for automobile wheel hub spraying, by mass fraction: including 1 part of graphene, 46 parts of thermoplastic acrylic resins, 20 parts of titanium dioxide, 10.5 parts of graphene dispersant BYK16, titanium dioxide dispersant BYK- 43 parts of P10, 0.5 parts of leveling agent, 56 parts of xylene.

[0083] A preparation method for a primer for automobile wheel hub spraying, comprising:

[0084] Thinning thermoplastic acrylic resins with xylene;

[0085] Add graphene dispersant and graphene to disperse;

[0086] Add titanium dioxide dispersant and titanium dioxide, continue to disperse;

[0087] A leveling agent is added to make the primer.

Embodiment 3

[0088] Embodiment 3: a kind of primer for automobile wheel hub spraying, by mass fraction: including 0.5 parts of graphene, 40 parts of thermoplastic acrylic resins, 15 parts of titanium dioxide, 0.3 parts of graphene dispersant WinSperse32040,3 parts of titanium dioxide dispersant Lubrizol366002 parts , 0.3 parts of leveling agent, 40 parts of xylene.

[0089] A preparation method for a primer for automobile wheel hub spraying, comprising:

[0090] Thinning thermoplastic acrylic resins with xylene;

[0091] Add graphene dispersant and graphene to disperse;

[0092] Add titanium dioxide dispersant and titanium dioxide, continue to disperse;

[0093] A leveling agent is added to make the primer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com