Low-temperature polymer conductive silver paste with low silver content, and preparation method thereof

A technology of conductive silver paste and polymer, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of weather resistance and stability gap, and achieve soft matt feeling, The effect of good printing reproducibility and low silver content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

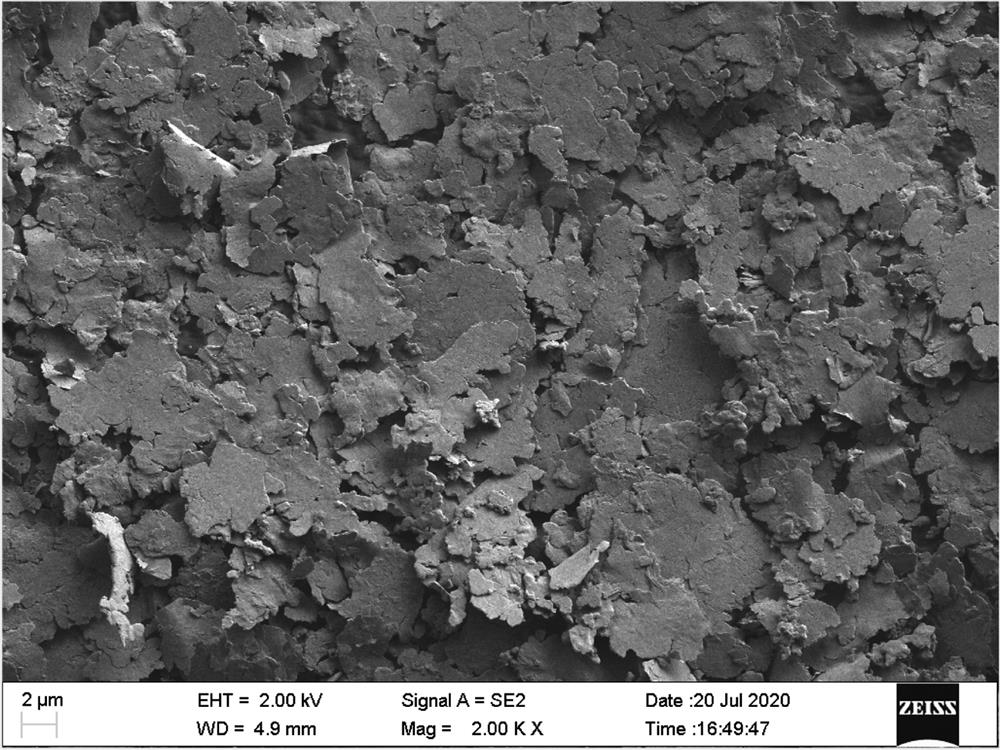

[0034] The conductive silver paste of the present embodiment is composed of the following mass percentage substances: flake silver powder SF-1#43%, VAGH-004 organic vehicle 43%, VMCH organic vehicle 8%, organic bentonite 0.8%, polyethylene micronized wax 0.5%, YL-2 glass resin 0.5%, 9100 varnish 0.7%, dibasic ester (DBE) 3.5%.

[0035] The D50 value of flake silver powder SF-1# is 3.49 μm, the VAGH-004 organic vehicle is 12% Dow VAGH-004 resin and fully stirred and dispersed in 88% DBE, and the VMCH organic vehicle is 20% Dow VMCH resin is fully stirred and dispersed in 80% DBE.

[0036] The preparation method of the above-mentioned conductive silver paste includes the following steps.

[0037] Step 1, premixing of the slurry: first, fully dissolve and mix VAGH-004 and VMCH organic vehicle, organic bentonite, polyethylene micronized wax, YL-2 glass resin, 9100 varnish, and DBE in a container using a high-speed disperser and Disperse evenly, then pour in flake silver powder S...

Embodiment 2

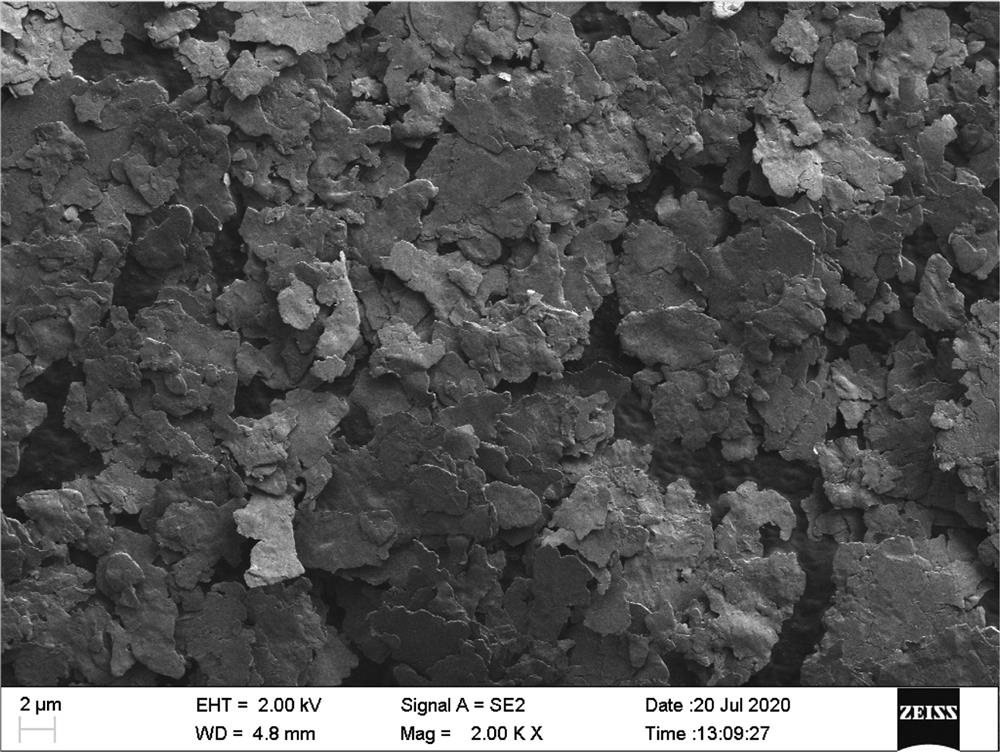

[0045] The conductive silver paste of the present embodiment is composed of the following mass percentage substances: flake silver powder SF-2#43%, VAGH-004 organic vehicle 43%, VMCH organic vehicle 8%, organic bentonite 0.8%, polyethylene micronized wax 0.5%, YL-2 glass resin 0.5%, 9100 varnish 0.7%, dibasic ester (DBE) 3.5%.

[0046] The D50 value of flaky silver powder SF-2# is 4.16 μm, the VAGH-004 organic vehicle is 12% Dow VAGH-004 resin and fully stirred and dispersed in 88% DBE, and the VMCH organic vehicle is 20% Dow VMCH resin is fully stirred and dispersed in 80% DBE.

[0047] The preparation method of the above-mentioned conductive silver paste includes the following steps.

[0048] Step 1, premixing of the slurry: first, fully dissolve and mix VAGH-004 and VMCH organic vehicle, organic bentonite, polyethylene micronized wax, YL-2 glass resin, 9100 varnish, and DBE in a container using a high-speed disperser and Disperse evenly, and then pour in flake silver powd...

Embodiment 3

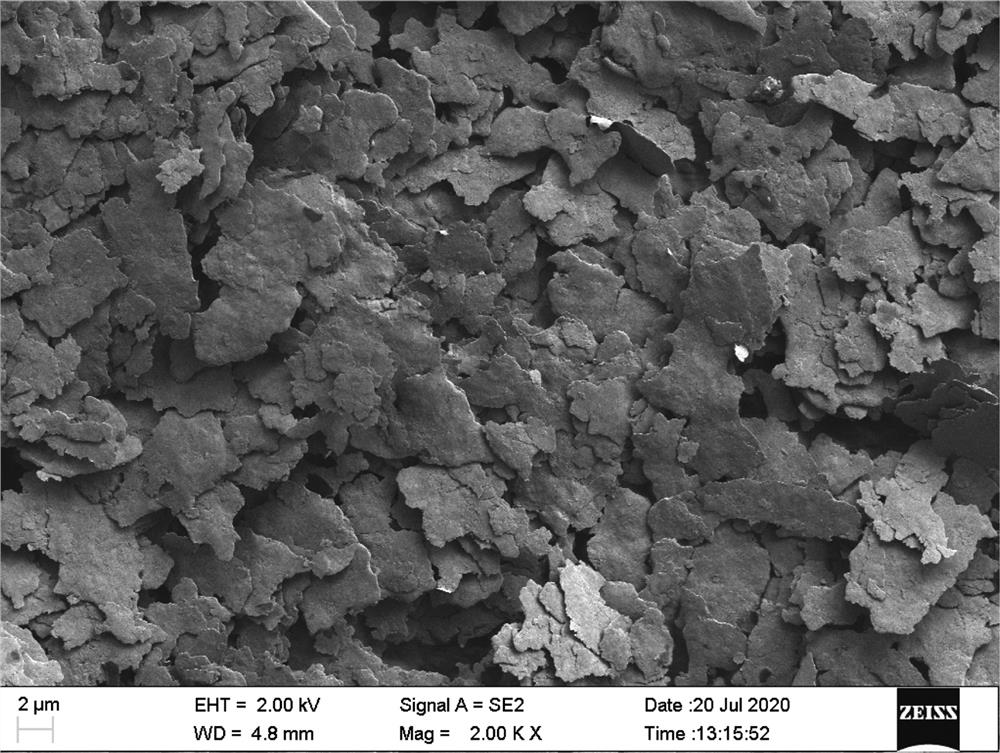

[0052] The conductive silver paste of the present embodiment is composed of the following mass percentage substances: flake silver powder SF-3#43%, VAGH-004 organic vehicle 43%, VMCH organic vehicle 8%, organic bentonite 0.8%, polyethylene micronized wax 0.5%, YL-2 glass resin 0.5%, 9100 varnish 0.7%, dibasic ester (DBE) 3.5%.

[0053] The D50 value of flaky silver powder SF-3# is 2.97 μm, the VAGH-004 organic vehicle is 12% Dow VAGH-004 resin and fully stirred and dispersed in 88% DBE, and the VMCH organic vehicle is 20% Dow VMCH resin is fully stirred and dispersed in 80% DBE.

[0054] The preparation method of the above-mentioned conductive silver paste includes the following steps.

[0055] Step 1, premixing of the slurry: first, fully dissolve and mix VAGH-004 and VMCH organic vehicle, organic bentonite, polyethylene micronized wax, YL-2 glass resin, 9100 varnish, and DBE in a container using a high-speed disperser and Disperse evenly, and then pour in flake silver powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com