Coextrusion composite polypropylene soft pipe and production method

A composite polypropylene and production method technology, applied in the direction of hoses, flexible tubular containers, pipes, etc., can solve the problems of increased cost of plasticizers, expensive plasticizers, safety performance concerns, etc., to achieve low heat sealing temperature, Effect of narrow molecular weight distribution and low crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

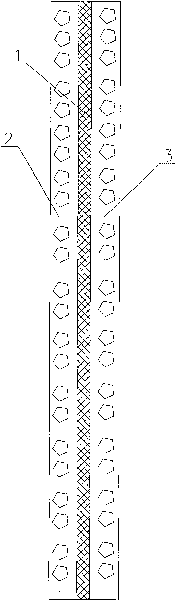

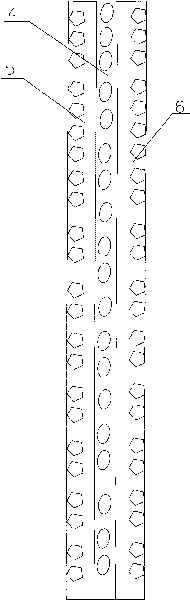

[0034] In Example 5, the raw materials used for the five layers of the hose body are respectively added to the respective single-screw extruders from each hopper, softened and melted, then co-extruded through the same molding mixing head, and then stretched, cooled, and vacuum-shaped , followed by heat treatment, traction, and cut to length in turn to obtain the hose body. The detailed production process is as follows:

[0035] 1. Start the power switch (main control box and cutter control box).

[0036] 2. Determine whether the running direction of each motor is correct.

[0037] 3. Turn on the extruder heater (screw and die), and preheat for about 60 minutes.

[0038] 4. Weigh and prepare the amount of raw materials required for each layer of hoppers and mix them evenly.

[0039] 5. After the screw extruder reaches the set temperature (the molding temperature of the polyethylene layer is 140 ° C ~ 190 ° C, metallocene-catalyzed random copolymerization of polypropylene or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com