Heat sealing film and preparation method thereof

A heat-sealing film, metallocene polypropylene technology, applied in chemical instruments and methods, flexible coverings, packaging, etc., can solve the problems of low sealing strength and high heat-sealing temperature of heat-sealing films, and achieve reduced packaging difficulty and low heat. The effect of sealing temperature and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a method for preparing a heat-sealing film, comprising the following steps:

[0060] Co-extruding polyethylene, metallocene ethylene propylene copolymer and polypropylene to obtain a hot-melt pipe comprising a first polyethylene layer, a first metallocene polypropylene layer and a polypropylene layer in sequential contact;

[0061] Blow molding the hot-melt pipe into a film, cooling and setting;

[0062] Corona treatment is performed on the outer surface of the film after cooling and setting to obtain a heat-sealing film.

[0063] The invention adopts a co-extrusion blow molding process to prepare the heat-sealing film, and the production process is relatively simple.

[0064] First, the raw material resins that form the first polyethylene layer, the first metallocene polypropylene layer and the polypropylene layer, namely polyethylene, metallocene ethylene propylene copolymer and polypropylene, are fed into a screw extruder for co-e...

Embodiment 1

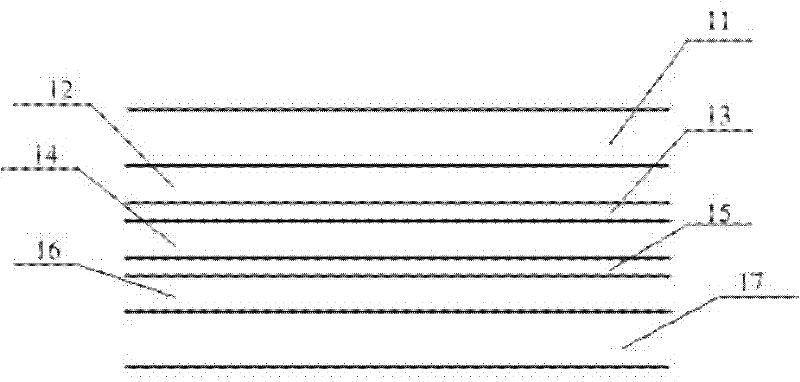

[0076] The seven-layer co-extrusion upper blow molding equipment produced by German W&H company, the model is VAREX, is used for the preparation of heat-sealing film:

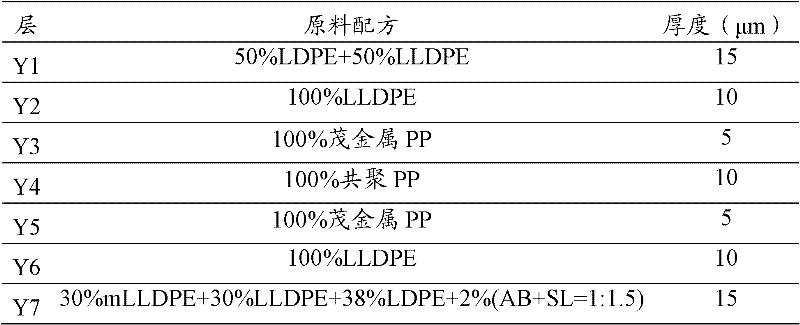

[0077] Add the first mixed polyethylene layer raw material (denoted as Y1), the first linear low density polyethylene layer raw material (denoted as Y2), the first metallocene polythene layer raw material (denoted as Y2) and the first metallocene polythene The propylene layer raw material (denoted as Y3), the polypropylene layer raw material (denoted as Y4), the second metallocene polypropylene layer raw material (denoted as Y5), the second linear low density polyethylene layer raw material (denoted as Y6) and the second Mix polyethylene layer raw materials (denoted as Y7), and the specific formula of each raw material is shown in Table 1.

[0078] Table 1 Example 1 preparation of each layer of the heat-sealing layer raw material formula used

[0079]

[0080]The raw materials in the seven barrels were co-e...

Embodiment 2

[0085] A heat-sealing film with a thickness of 70 μm was prepared according to the method and equipment provided in Example 1. The difference is that the specific formula of each raw material is shown in Table 4.

[0086] Table 4 The formula of raw materials used for each layer of the heat-sealing layer prepared in Example 2

[0087]

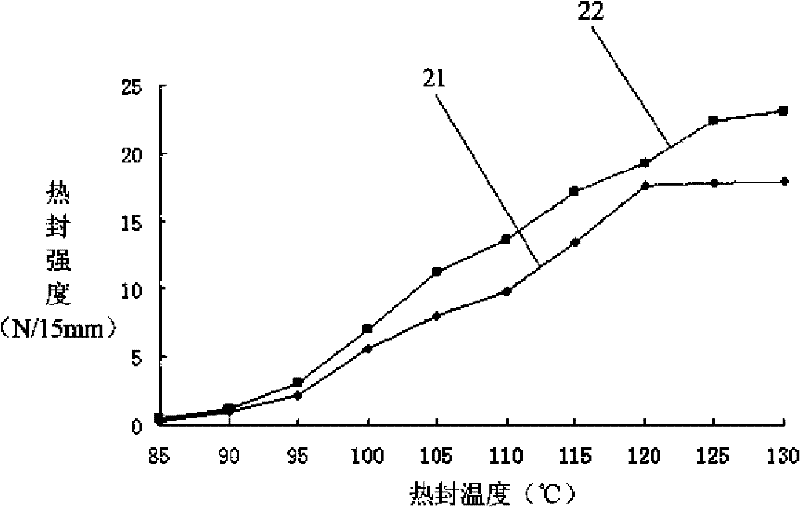

[0088] The heat-sealing performance test was carried out on the heat-sealing film, and the results are shown in Table 2. Table 2 shows the heat-sealing performance test results of the heat-sealing films provided in the examples and comparative examples of the present invention.

[0089] The heat-sealing film was composited with a PET film with a thickness of 12 μm to obtain a composite film, and the heat-sealing performance test was carried out on the composite film. The results are shown in Table 3. Table 3 shows the properties of the composite films provided by the embodiments of the present invention and comparative examples. Heat sealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com