Ultralow temperature heat-sealing tape-casting polypropylene aluminum plating film

A technology for casting polypropylene and aluminized films, used in the fields of lamination, rapid packaging, packaging, and printing, it can solve the problems of film delamination, film adhesion, and low heat sealing temperature, achieve good aluminization adaptability, reduce heat The effect of sealing temperature and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

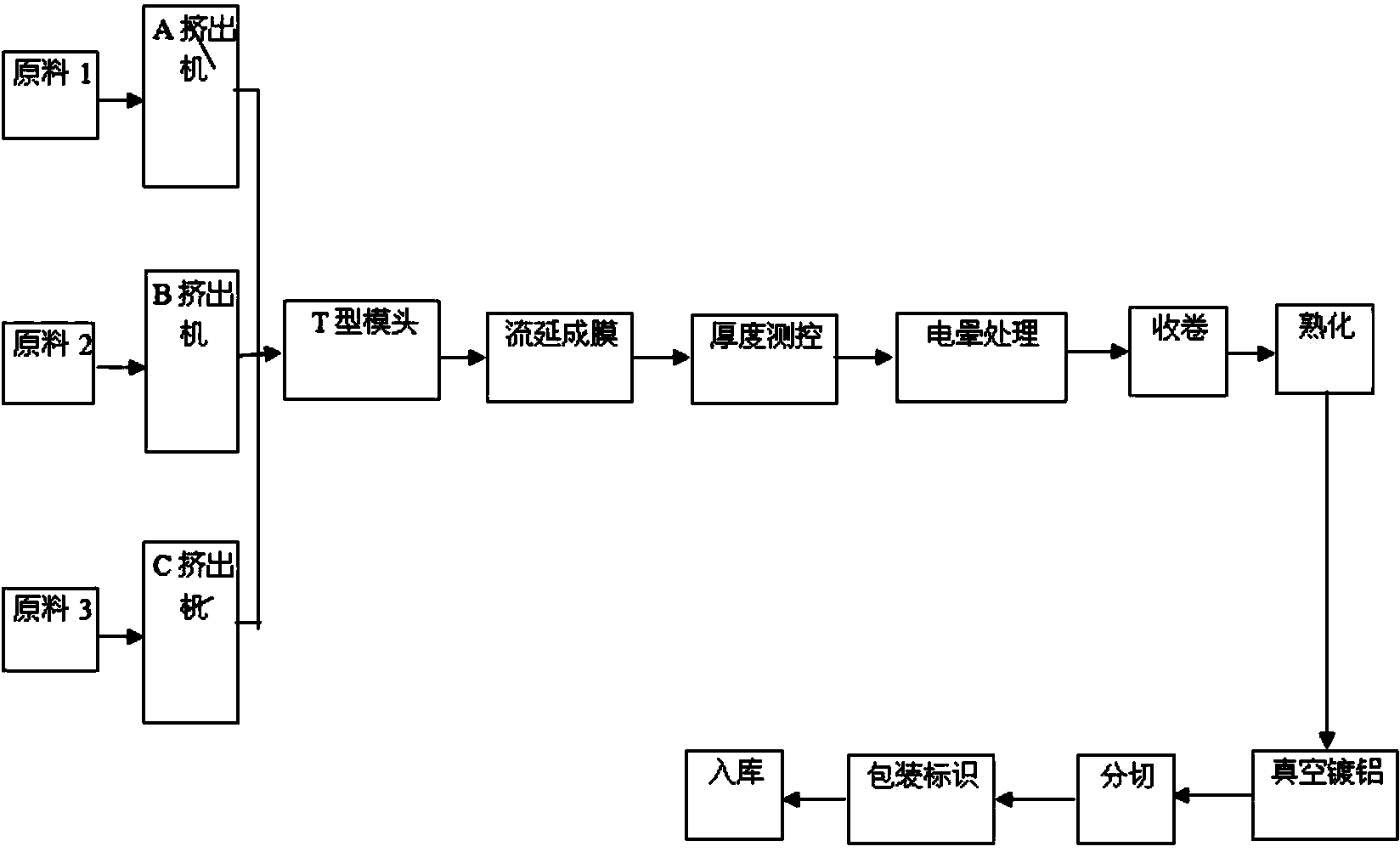

Method used

Image

Examples

Embodiment 1

[0012] An ultra-low temperature heat-sealed cast polypropylene aluminum-coated film. The base film is produced by a three-layer co-extrusion casting method. The three-layer structure is: a corona layer, an intermediate layer and a heat-sealing layer. The corona layer of the base film is vacuum-plated aluminized, and the layer thickness ratios of the corona layer, the intermediate layer and the heat-sealing layer structure are respectively 20% of the corona layer, 70% of the intermediate layer, and 10% of the heat-sealing layer. The corona layer is composed of polypropylene and maleic anhydride graft-modified polypropylene, the weight ratio of the polypropylene and maleic anhydride graft-modified polypropylene is 10:4; the middle layer is composed of identical Composed of stereotactic polypropylene; the heat-sealing layer is composed of polypropylene copolymer, anti-sticking agent and octamethylcyclotetrasiloxane in a weight ratio of 98:7:1.

[0013] The invention relates to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com